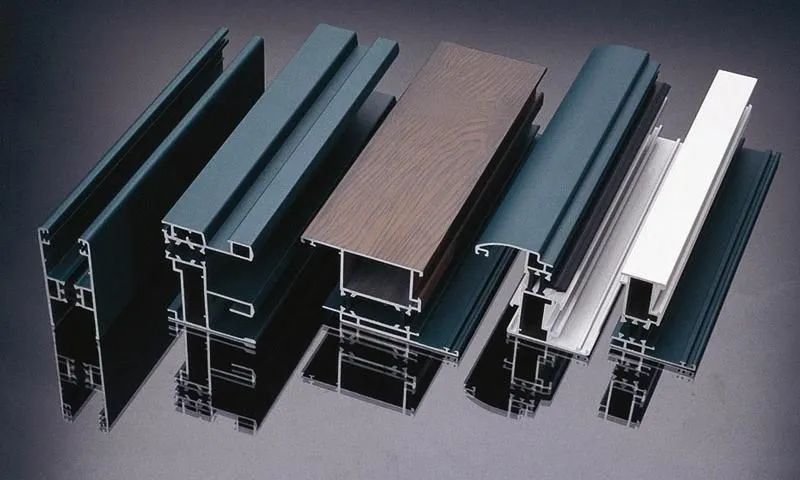

Wenn es um Metalloberflächen geht, stechen oft zwei Optionen hervor: Eloxieren Und Pulverbeschichtung. Beide Methoden verbessern die Haltbarkeit, Aussehen, Und Korrosionsbeständigkeit von Metalloberflächen – insbesondere Aluminium. Obwohl sie auf den ersten Blick ähnlich erscheinen mögen, dienen sie unterschiedlichen Zwecken. unterschiedliche Zwecke abhängig von den Anforderungen Ihres Projekts.

In diesem Leitfaden erklären wir Ihnen alles, was Sie wissen müssen. Von der Kernprozesse Und visuelle Unterschiede zum kosten, Anwendungen, Und wie man die richtige Oberflächenbehandlung auswählt, Sie erhalten so ein klares Bild davon, welche Option am besten zu Ihren Bedürfnissen passt. Legen wir los!

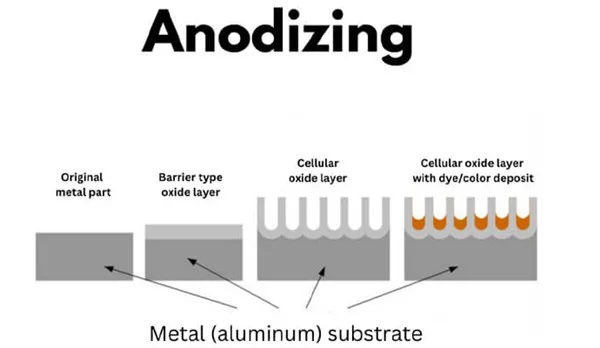

Was ist Anodisieren?

Eloxieren ist ein elektrochemischer Prozess, der die natürliche Oxidschicht auf Metallen verstärkt – am häufigsten Aluminium. Diese Schicht wird dicker, härter und schützender und verleiht der Oberfläche ausgezeichnete Korrosionsbeständigkeit, verbessert Kratzfestigkeit, und eine saubere, metallische Oberfläche. Im Gegensatz zu Lack oder Pulverbeschichtung wird durch Anodisieren eine glatte, metallische Oberfläche erzeugt. Teil des Metalls, Es splittert, blättert oder bröckelt daher mit der Zeit nicht ab.

Es bietet außerdem die Flexibilität, hinzuzufügen Farbe durch Färben, ohne Schichten auf der Oberfläche aufzubauen – perfekt für Projekte, die ein eleganter, metallischer Look mit zusätzlichem Schutz.

Wichtigste Vorteile der Anodisierung:

Erstellt ein härtere Oberfläche als Pulverbeschichtung

Exzellent UV- und Witterungsbeständigkeit

Produziert ein natürliches metallisches Aussehen

Unterstützt Farbtönung ohne Ablagerungen oder Abblättern

Anodisieren eignet sich ideal für Projekte im Außenbereich, architektonische Elemente und alle Anwendungen, bei denen Langlebigkeit und eine raffinierte Ästhetik Gegenstand.

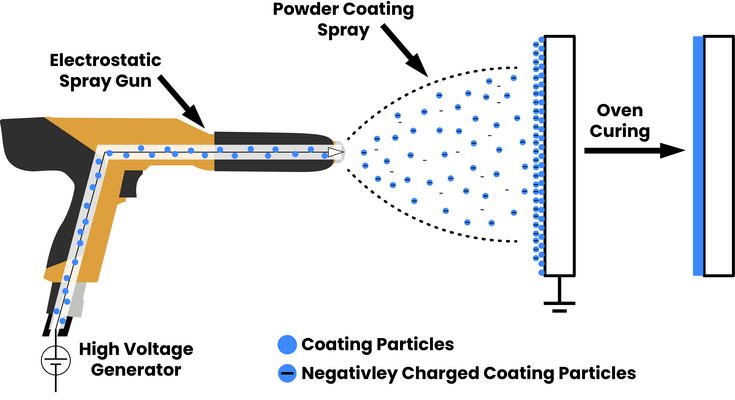

Was ist Pulverbeschichtung?

Pulverbeschichtung ist beliebt Trockenveredelungsverfahren das verwendet elektrostatisch geladenes Pulver, auf eine Oberfläche aufgetragen und dann durch Hitze gehärtet. Das Ergebnis? Eine glatte, strapazierfähige und farbenfrohe Schicht, die sich fest mit dem Material verbindet. Im Gegensatz zu Flüssigfarbe, Es tropft und verläuft nicht – und es deckt Oberflächen gleichmäßig ab, selbst bei komplexen Formen.

Es funktioniert auf Metalle wie Aluminium und Stahl, und sogar einige nichtmetallische Oberflächen wie MDF, Dadurch eignet es sich vielseitig sowohl für industrielle als auch für dekorative Zwecke.

Wichtigste Vorteile der Pulverbeschichtung:

Angebote glatte dekorative Oberflächen in matten, glänzenden oder strukturierten Ausführungen

Erstellt ein dickere Beschichtung das stoßfest, chemikalienbeständig und verschleißfest ist

Kostengünstig für Projekte mit hohem Volumen

Enthält niedrige VOC-Konzentrationen, wodurch es zu einem grüner Oberflächenbehandlung

Wenn Sie einen lebendiger, einheitlicher Look Pulverbeschichtung ist aufgrund ihrer hohen Haltbarkeit und geringeren Kosten eine beliebte Wahl – insbesondere für Produkte, die keine extreme Beständigkeit gegenüber Umwelteinflüssen erfordern.

Wesentliche Unterschiede zwischen Anodisieren und Pulverbeschichten

| Besonderheit | Eloxieren | Pulverbeschichtung |

| Verfahren | Elektrochemische Oxidation | Elektrostatische Sprühtechnik und Wärmehärtung |

| Haltbarkeit | Harte, integrierte Oberfläche | Dicke, schützende Oberflächenschicht |

| Farbspektrum | Begrenzte, natürliche Metallic-Töne | Große Auswahl an leuchtenden Farben |

| UV-Beständigkeit | Exzellent | Sehr gut, kann aber mit der Zeit nachlassen. |

| Korrosionsbeständigkeit | Hoch (insbesondere bei Abdichtung) | Hoch (bei entsprechender Vorbereitung) |

| Kosten | Im Allgemeinen höher | Kostengünstiger |

| Oberflächenbeschaffenheit | Metallisch, weist Materialfehler auf | Glatt, kaschiert Unreinheiten |

| Umweltfreundlichkeit | Mäßig (kann Nebenprodukte erzeugen) | Hoher Wert (keine VOCs oder Lösungsmittel) |

1. Anwendungen und ideale Anwendungsfälle

Zu wissen, wann man wählen sollte Anodisieren vs. Pulverbeschichten Das spart Zeit, Geld und Nerven. Jede Oberflächenbehandlung glänzt in bestimmten Anwendungsfällen – schauen wir uns das also genauer an.

Wann man Anodisieren anwendet

Anodisieren ist ideal für Luft- und Raumfahrtteile, Marinekomponenten, Architektur, und jede Anwendung, die eine dauerhafte, strapazierfähige und UV-beständige Oberfläche. Es eignet sich auch perfekt für Projekte, bei denen Kratzfestigkeit Und metallische Ästhetik sind von entscheidender Bedeutung.

Wann man Pulverbeschichtung einsetzt

Pulverbeschichtungs-Anzüge Autoteile, Geräte, Möbel, Und Beschilderung wo leuchtende Farben, dickere Deckkraft oder Sonderausführungen werden bevorzugt. Es eignet sich am besten für Artikel im Innen- und Außenbereich, bei denen kleinere Oberflächenfehler kaschiert werden sollen.

2. Kostenvergleich

Pulverbeschichtung ist in der Regel günstiger aufgrund des einfacheren Aufbaus und der einfacheren Materialien. Anodisieren ist teurer aufgrund spezieller Ausrüstung, längerer Bearbeitungszeiten und strengerer Chemikalienhandhabung. Die Anodisierung hingegen Langlebigkeit kann die höheren Anfangskosten bei Hochleistungsanwendungen ausgleichen.

3. Ästhetische und farbliche Unterschiede

Durch Anodisieren erhält man metallischer Look das sich harmonisch in den Untergrund einfügt und so eine elegante, natürliche Haptik erzeugt. Seine Farben sind oft weniger lebendig, Pulverbeschichtung bietet, dass sie nicht abblättert. kräftige, einheitliche Farbtöne und lässt sich problemlos an Markenfarben anpassen. Außerdem kaschiert es Mängel besser.

4. Umweltauswirkungen

Pulverbeschichtung ist im Allgemeinen mehr umweltfreundlich, emittierend NEIN VOCs und erzeugt dabei nur minimalen Abfall. Beim Anodisieren können je nach verwendeten Chemikalien gefährliche Abfälle entstehen, aber moderne Methoden Verwenden Sie recycelbare Elektrolyte und begrenzen Sie die Emissionen. Eine ordnungsgemäße Abfallentsorgung ist in beiden Fällen entscheidend.

5. Wartungsanforderungen

Beide Endlagen sind einfach zu pflegen. Einfach regelmäßig reinigen mit milde Seife und Wasser– Keine aggressiven Chemikalien oder Schleifmittel. Pulverbeschichtungen können bei Stößen zerkratzen, während eloxierte Oberflächen können matt werden in stark beanspruchten Bereichen. Durch schonende Pflege bleibt die Oberfläche stets frisch und langlebig.

Kann man beides kombinieren?

Rein technisch gesehen ja – aber ideal ist es nicht. Das Aufbringen von Pulverbeschichtung auf eloxiertes Aluminium erfordert spezielle Oberflächenvorbereitung und können die Vorteile beider Oberflächenbehandlungen aufheben. Sofern Sie keine sehr speziellen Anforderungen haben, ist es sinnvoller, Wählen Sie eine Oberfläche. basierend auf den Anforderungen Ihres Projekts hinsichtlich Haltbarkeit und Optik.

Wie man die richtige Oberflächenbehandlung auswählt

Sie sind sich nicht sicher, welche Oberfläche am besten passt? Wir erklären es Ihnen ganz einfach. Fragen Sie sich, was Ihnen am wichtigsten ist –Haltbarkeit, Farbe, kosten, oder sehen—und passen Sie es Ihren Bedürfnissen an:

UmfeldWenn Ihr Produkt extremen Witterungsbedingungen ausgesetzt ist oder direkte UV-Strahlung, Die Anodisierung bietet einen besseren Langzeitschutz.

FarbbedürfnisseWünschen Sie sich kräftige Farbtöne oder Markenfarben? Pulverbeschichtung bietet Ihnen lebendigere und vielfältigere Optionen.

HaltbarkeitWenn die Oberfläche sieht Reibung oder wiederholter Verschleiß, Die harte Oxidschicht der Anodisierung hält länger.

Budget: Zusammenarbeit mit begrenzte MittelPulverbeschichtung ist in der Regel in der Anschaffung günstiger.

ÄsthetikIch liebe das roher metallischer GlanzAnodisieren ist die bessere Wahl. Bevorzugen Sie ein glattes, makelloses FinishPulverbeschichtung ist die beste Lösung.

FAQs

1. Welche Oberflächenbehandlung ist haltbarer – Anodisieren oder Pulverbeschichten?

Anodisieren ist in der Regel langlebiger, da das Anodisieren ein Teil der Metalloberfläche wird. Es eignet sich besonders gut für rauen Außenumgebungen oder stark beanspruchten Bereichen.

2. Kann man eloxiertes Aluminium pulverbeschichten?

Ja, aber das ist nicht optimal. Die eloxierte Oberfläche muss … geschliffen oder geätzt Damit das Pulver haftet. Sie erzielen in der Regel bessere Ergebnisse, wenn Sie von Anfang an eine Methode wählen.

3. Ist die Pulverbeschichtung wasserdicht?

Pulverbeschichtung ist wasserfest. Wenn es aber abplatzt oder Risse bekommt, kann Wasser an das darunterliegende Metall gelangen und Korrosion verursachen.

Abschluss

Sowohl Anodisieren als auch Pulverbeschichten bieten langlebige und attraktive Oberflächenveredelungen für Metalle. Die Wahl der richtigen Lösung hängt von den Bedürfnissen Ihres Projekts ab.Anodisierung für UV-Beständigkeit und Kratzfestigkeit, oder Pulverbeschichtung für Farbvielfalt und Kosteneffizienz. Berücksichtigen Sie Anwendungsbereich, Budget und Umfeld, bevor Sie Ihre Entscheidung treffen.

Sie sind sich noch nicht sicher, welche Oberflächenbehandlung die richtige für Ihr Produkt ist? Kontaktieren Sie uns noch heute Wir bieten Ihnen fachkundige Beratung, individuell auf Ihr Projekt zugeschnitten. Wir helfen Ihnen, die zuverlässigste und kostengünstigste Lösung auszuwählen, die dauerhafte Leistung und eine ansprechende Ästhetik gewährleistet.

![Apro-Logo - Einblicke in den Markt für Aluminiumtüren und -fenster [2030] - APRO Apro-Logo](https://aprowin.com/wp-content/uploads/2024/08/Apro-logo.webp)

![APRO-Logo weiß – Markteinblicke in den Markt für Aluminiumtüren und -fenster [2030] – APRO APRO Logo weiß](https://aprowin.com/wp-content/uploads/2024/07/APRO-logo-white.webp)