The aluminum door and window industry is experiencing rapid growth, driven by rising demand for durable, energy-efficient, and modern building materials.

Aluminum’s lightweight structure, corrosion resistance, and sleek design make it a top choice for both residential and commercial construction projects worldwide.

With urbanization on the rise and sustainability becoming a priority, the market for aluminum doors and windows is expanding rapidly.

Entrepreneurs entering this industry have a golden opportunity to tap into a sector that combines steady demand with long-term growth potential.

Whether you’re a seasoned professional or a budding entrepreneur, this business offers exciting prospects to build a profitable and future-ready enterprise.

Market Overview

Starting an aluminum door and window manufacturing business is an exciting opportunity, but understanding the market landscape is essential for success. In this section, we’ll explore the key global trends, regional opportunities, and target customer segments to help you make informed decisions.

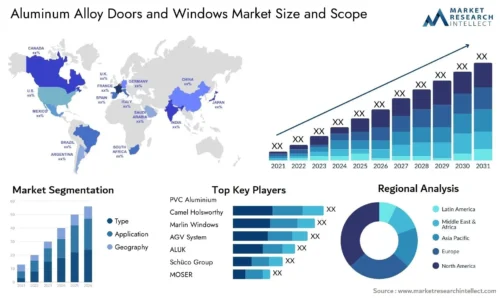

Global Market Trends

The global market for aluminum doors and windows is booming, thanks to rapid urbanization, growing infrastructure projects, and increasing demand for sustainable construction materials.

Aluminum has become a preferred choice due to its durability, lightweight nature, and resistance to corrosion.

According to recent market studies, the global aluminum door and window market was valued at over $72 billion in 2020 and is projected to exceed $118 billion by 2028, growing at a compound annual growth rate (CAGR) of approximately 6.2%.

This growth is driven by rising demand for energy-efficient building solutions, modern architectural trends, and the replacement of outdated wooden and steel installations.

Additionally, aluminum products are gaining popularity for their ability to improve thermal insulation and reduce energy consumption, making them an eco-friendly choice in both residential and commercial settings.

As environmental concerns continue to rise, the market is shifting towards greener practices, further fueling demand for aluminum-based solutions.

In short, the aluminum door and window market isn’t just growing—it’s thriving.

Entrepreneurs stepping into this space are tapping into an industry poised for long-term expansion.

Regional Opportunities

While the global market is promising, certain regions stand out for their exceptional growth potential.

Asia-Pacific: This region leads the global market, with countries like China, India, and Japan driving demand. Rapid urbanization, government investments in smart city projects, and increasing disposable incomes make this market highly lucrative.

North America: In this region, the focus is on renovation and remodeling projects, especially in commercial spaces. Energy efficiency and sustainable construction practices are key drivers here.

Europe: With stringent building regulations emphasizing energy-efficient materials, aluminum doors and windows are in high demand. Renovation projects in older structures are a major growth factor.

Middle East and Africa: Infrastructure projects in cities like Dubai and Riyadh are driving significant demand for premium aluminum products. Modern architectural designs in commercial and residential spaces create consistent opportunities.

By focusing on these regions, you can strategically position your business to capitalize on growing demand and maximize your market reach.

Target Market Analysis

Understanding your target market is a critical step in building a successful aluminum door and window business.

Here are the key customer segments you should focus on:

Residential Customers: Homeowners looking to renovate or build modern, energy-efficient homes are a key market segment. They value sleek designs, durability, and energy-saving benefits.

Commercial Clients: Offices, retail spaces, hotels, and restaurants require aluminum doors and windows for both functionality and aesthetic appeal. Security, energy efficiency, and brand image often guide their purchasing decisions.

Contractors and Builders: These professionals play a pivotal role in large-scale projects. Partnering with them can ensure bulk orders and long-term contracts.

Architects and Designers: Architects often specify materials for projects, making them important influencers in purchasing decisions. Building strong relationships with architects can significantly boost your visibility in the industry.

Renovation and Remodeling Market: Many existing structures are transitioning from wooden or steel installations to aluminum due to its durability and aesthetic appeal. This market provides a steady flow of orders.

By identifying and understanding these segments, you’ll be better equipped to tailor your marketing, pricing, and product strategies to meet their needs.

Business Plan Essentials

Every successful business starts with a strong plan.

Your aluminum door and window manufacturing venture is no different.

In this section, we’ll guide you through setting objectives, exploring business models, and conducting a SWOT analysis to lay the foundation for success.

Defining Business Objectives

Before diving into manufacturing, ask yourself: What do I want to achieve with this business?

Clear objectives are like a GPS—they keep you on track and help measure progress.

- Are you focusing on mass production or high-end custom designs?

- Do you want to dominate a local market or expand globally?

- Are your goals revenue-driven, or do you aim to provide innovative, sustainable solutions?

Setting SMART (Specific, Measurable, Achievable, Relevant, and Time-bound) goals will give you clarity and direction.

For example, “Achieve a production capacity of 10,000 units per year by the end of Year 2” is far more actionable than simply saying, “Grow production.”

A clear set of objectives not only keeps your team aligned but also helps when communicating your vision to potential investors and partners.

Business Model Options

Your business model determines how you’ll operate, generate revenue, and serve customers.

Here are some common models in the aluminum door and window manufacturing industry:

Manufacturing and Installation: You handle both production and installation. This model ensures quality control but requires significant investment in machinery and skilled labor.

Wholesale and Distribution: Focus on producing products and supplying them to retailers or contractors. It reduces overhead costs but depends heavily on strong distribution networks.

Retail Showroom: Operate a physical space where customers can browse and order products. You can combine this with installation services to offer a complete package.

E-commerce Model: Sell products online via your website or third-party platforms. This model has lower operational costs and can reach a broader audience.

Franchise Model: Partner with an established aluminum door and window brand to leverage their reputation and resources. This model requires franchise fees but reduces the risk of starting from scratch.

Each model has its pros and cons, so carefully evaluate your resources, target market, and long-term goals before making a choice.

SWOT Analysis

A SWOT analysis is a simple yet powerful tool to assess your business landscape. Here’s how it breaks down:

- Strengths: What advantages does your business have? (e.g., high-quality materials, skilled workforce, innovative designs)

- Weaknesses: What challenges might you face? (e.g., high startup costs, dependency on suppliers)

- Opportunities: What external factors can you leverage? (e.g., growing demand for eco-friendly products, government infrastructure projects)

- Threats: What potential risks could impact your business? (e.g., market competition, rising raw material costs)

By identifying these four factors, you can create strategies to capitalize on your strengths, address weaknesses, seize opportunities, and mitigate threats.

Legal and Regulatory Requirements

Starting an aluminum door and window manufacturing business isn’t just about great products and strong sales—it’s also about playing by the rules.

Ensuring your business complies with legal and regulatory requirements is essential for long-term success and avoiding costly penalties.

Let’s break it down.

Business Registration and Licensing

Before you start cutting aluminum sheets and assembling windows, your business needs a legal identity.

Depending on your location, you’ll need to decide on the structure of your business.

The most common options include:

- Sole Proprietorship: Simple to set up, but you’ll be personally liable for any business debts.

- Limited Liability Company (LLC): Protects personal assets and offers better credibility with clients and suppliers.

- Partnership: Ideal if you’re teaming up with someone, with shared responsibilities and liabilities.

Once you’ve decided on the structure, the next steps are:

- Registering your business name.

- Obtaining a Trade License from your local authority.

- Getting a Tax Identification Number (TIN) or equivalent.

- Securing any sector-specific permits required for aluminum processing or manufacturing.

Each region has its own set of rules, so it’s a good idea to consult with a local legal advisor to ensure you’re fully compliant.

Environmental Compliance

Aluminum manufacturing processes, particularly anodizing and surface treatment, can produce chemical waste.

This means you need to address environmental responsibilities seriously.

- Waste Disposal: Implement a proper waste management system to handle byproducts and avoid environmental hazards.

- Pollution Control Measures: Install necessary filtration systems and follow local guidelines to minimize air and water pollution.

- NOC from Pollution Control Board: In many regions, you’ll need a No Objection Certificate (NOC) to operate legally.

Sustainable practices aren’t just good for the planet—they also boost your brand image and attract environmentally conscious customers.

Product Safety Standards

Your aluminum doors and windows aren’t just products; they’re integral to safety and energy efficiency in homes and buildings.

Meeting safety standards ensures customer trust and avoids legal complications.

- Adhere to Local Building Codes to meet structural integrity requirements.

- Ensure compliance with ISO Certifications or other relevant product safety standards.

- Regularly test your products for durability, load resistance, and thermal performance.

Certifications aren’t just stamps on paper—they’re your ticket to entering competitive markets and standing out from low-quality competitors.

Financial Planning and Investment

Money matters—and when it comes to starting an aluminum door and window manufacturing business, smart financial planning is non-negotiable.

Let’s talk numbers, funding options, and how to ensure your investment turns into profit.

Initial Investment Requirements

Starting your aluminum manufacturing business isn’t pocket change, but with proper planning, it’s manageable.

Here’s where your initial budget will likely go:

- Equipment and Machinery: Cutting machines, corner crimping tools, polishing units, and assembly tables.

- Raw Materials: Aluminum profiles, glass panels, hinges, screws, and other hardware.

- Workforce Costs: Skilled technicians, laborers, administrative staff, and sales personnel.

- Facility Setup: Rent, utilities, and safety equipment for your workshop.

Estimated Cost Breakdown (Approximate Example):

- Machinery and Equipment: 40% of your budget

- Raw Materials: 30%

- Facility Setup: 15%

- Workforce and Training: 10%

- Miscellaneous (licenses, marketing, initial stock): 5%

While these percentages may vary based on your scale, they provide a general idea of what to expect.

Financing Options

Not everyone has a vault of gold ready to kickstart a manufacturing business—and that’s okay!

There are several financing options available:

- Personal Savings: The most straightforward route, giving you full control without debt.

- Bank Loans: Approach banks with a strong business plan to secure loans with competitive interest rates.

- Government Grants: Some regions offer grants for manufacturing businesses, especially if they involve sustainable practices.

- Crowdfunding: Platforms like Kickstarter allow you to present your project to a global audience and raise funds.

- Angel Investors: If your business plan showcases innovation and scalability, investors may jump on board.

Each option has its pros and cons, so carefully evaluate your repayment capabilities before diving in.

Profitability Analysis

A profitable business isn’t just about revenue—it’s about managing costs smartly.

Here are some key factors to consider:

- Material Costs: Keep track of fluctuations in aluminum and glass prices. Buying in bulk can help reduce costs.

- Production Efficiency: Minimize waste, optimize processes, and invest in skilled labor.

- Pricing Strategy: Strike a balance between competitiveness and profitability. Don’t undersell your products just to gain market entry.

- Revenue Streams: Diversify your income by offering installation services or maintenance packages.

Profit Margin Benchmark: Many aluminum door and window businesses aim for a profit margin of 15-20%, depending on scale and efficiency.

In short, understanding where your money goes, how it comes back, and what profit margins you’re aiming for will set you up for long-term financial health.

Equipment and Technology

When it comes to aluminum door and window manufacturing, having the right equipment and embracing modern technology can make or break your business.

This section will walk you through the essential machinery you’ll need and how technology can optimize your operations.

Essential Machinery

Starting an aluminum door and window manufacturing business isn’t just about having a workshop—it’s about equipping it with the right tools.

High-quality machinery ensures precision, efficiency, and consistency in your products.

Here are the key machines you’ll need:

- Aluminum Cutting Machine: Ensures precise and clean cuts for aluminum frames. Accuracy is crucial here to minimize material waste.

- End Milling Machine: Used for processing the ends of aluminum profiles, ensuring they fit perfectly during assembly.

- Corner Crimping Machine: Essential for connecting aluminum frames at precise angles, ensuring a strong and secure fit.

- Drilling and Milling Machine: Used for drilling holes and slots in aluminum profiles for locks, handles, and hinges.

- Glass Cutting Table: Needed for cutting glass panels to the exact size required for window installations.

- Polishing and Buffing Machine: Gives aluminum frames a smooth and polished finish, enhancing their aesthetic appeal.

- Anodizing Equipment: For surface treatment to improve corrosion resistance and add a sleek finish.

Investing in high-quality machinery might seem expensive initially, but it’s an investment that pays off in product quality, reduced waste, and long-term savings.

Technology Integration

In today’s competitive market, relying solely on manual processes can hold you back.

Integrating modern technology into your aluminum manufacturing business is not just a luxury—it’s a necessity.

- Automation Tools: Automated cutting and crimping machines reduce errors and improve production speed.

- Computer-Aided Design (CAD) Software: Design and prototype aluminum doors and windows digitally before production begins. This minimizes errors and ensures customer satisfaction.

- ERP (Enterprise Resource Planning) Systems: Manage inventory, production schedules, and customer orders seamlessly from a single platform.

- Quality Control Systems: Use technology to perform automated quality checks on finished products.

By embracing automation and smart manufacturing tools, you’ll reduce costs, minimize waste, and improve your ability to deliver high-quality products consistently.

In short: Invest in essential machinery and embrace smart technology from the start.

It’ll streamline your operations, boost productivity, and give your business a competitive edge.

Sourcing Raw Materials

Your aluminum door and window products are only as good as the materials you use.

Reliable suppliers and efficient inventory management play a huge role in maintaining quality, reducing waste, and keeping costs under control.

Reliable Suppliers

Finding trustworthy suppliers for your raw materials is one of the first steps toward building a sustainable business.

You’ll primarily need:

- Aluminum Profiles: These are the building blocks of your products. Look for suppliers who offer high-grade, corrosion-resistant aluminum.

- Glass Panels: Choose suppliers who provide toughened, laminated, or energy-efficient glass panels, depending on your product line.

- Hardware Components: Locks, hinges, handles, and screws must be durable and rust-resistant.

How to Choose a Reliable Supplier:

- Look for suppliers with a proven track record in the industry.

- Compare pricing, but don’t compromise on quality to save a few bucks.

- Ensure timely delivery and check their ability to handle bulk orders.

- Build long-term relationships to secure better pricing and priority service.

Consider attending trade shows or industry expos to meet potential suppliers face-to-face.

It’s also a great way to discover new materials and innovative products.

Inventory Management

Efficient inventory management ensures that you always have enough raw materials to meet production demands without overspending on excess stock.

Here’s how you can optimize your inventory:

- Use Inventory Management Software: Track material levels, monitor usage trends, and set automatic reorder alerts.

- Just-in-Time (JIT) Strategy: Order raw materials based on real-time production needs to reduce storage costs.

- Supplier Partnerships: Build trust with key suppliers to ensure quick restocking during peak production periods.

- Minimize Waste: Implement strict quality checks on raw materials to avoid defects that lead to material wastage.

By striking the right balance between having enough materials and avoiding overstock, you’ll save money, reduce waste, and keep your operations running smoothly.

Human Resources and Workforce Management

Behind every successful aluminum door and window manufacturing business is a team of skilled, motivated, and well-trained professionals.

Your workforce is not just a set of employees—they’re the driving force behind your products, your quality, and your reputation.

In this section, we’ll talk about building a strong team, keeping them trained, and ensuring their safety at work.

Skilled Workforce

Hiring the right people is one of the most critical steps in setting up your business.

Each role plays a unique part in keeping operations smooth and efficient.

Here are the key roles you’ll need to fill:

- Technicians and Fabricators: These are the hands-on experts who cut, shape, and assemble aluminum doors and windows. Experience in operating machinery and understanding technical drawings is essential.

- Assemblers: Once the materials are cut and prepared, assemblers put the pieces together with precision. Attention to detail is crucial here.

- Sales Staff: Your sales team bridges the gap between your factory and your customers. They need to understand your products inside out to address client needs effectively.

- Administrative Staff: From managing paperwork to coordinating logistics, administrative staff ensure smooth day-to-day operations.

When hiring, look for candidates who not only have technical skills but also align with your company’s values.

A motivated and committed team will always go the extra mile.

Training Programs

Hiring skilled staff is just the beginning—continuous training is what keeps them sharp, efficient, and up-to-date with industry trends.

- Technical Training: Regular workshops on using advanced machinery, understanding safety protocols, and handling new technology tools.

- Quality Assurance Training: Educate your team on quality standards and inspection techniques to minimize defects.

- Sales and Customer Service Training: Equip your sales team with product knowledge and effective communication strategies.

- Health and Safety Training: Train your workforce on safety measures, emergency procedures, and equipment handling.

Investing in your employees’ skills isn’t just about improving productivity—it also boosts employee morale and reduces turnover rates.

Workplace Safety

Safety isn’t optional—it’s a non-negotiable part of running a responsible manufacturing business.

Aluminum fabrication involves heavy machinery, sharp tools, and potentially hazardous materials, so safety protocols must always come first.

Here’s how to maintain a safe work environment:

- Protective Gear: Provide safety goggles, gloves, ear protection, and steel-toed boots for all staff.

- Clear Safety Protocols: Display safety guidelines prominently in the workshop.

- Emergency Equipment: Ensure fire extinguishers, first aid kits, and emergency exits are easily accessible.

- Regular Inspections: Conduct routine safety audits to identify and address potential hazards.

A safe workplace isn’t just about compliance—it’s about building trust with your team and creating an environment where they feel valued and protected.

Production Process

The heart of your aluminum door and window manufacturing business lies in your production process.

This is where raw materials transform into sleek, functional, and durable products.

Let’s break down the process step by step and explore how quality control keeps everything on track.

Step-by-Step Manufacturing Process

Manufacturing aluminum doors and windows involves a series of precise steps, each playing a crucial role in the final product’s quality and durability.

Here’s a simplified breakdown:

- Material Procurement: High-quality aluminum profiles, glass panels, and hardware components are sourced from reliable suppliers.

- Design and Cutting: Using CAD software, designs are finalized, and aluminum profiles are cut to precise specifications with cutting machines.

- End Milling: Aluminum ends are milled to ensure perfect alignment during assembly.

- Frame Assembly: Profiles are assembled using corner crimping machines and secured with screws and brackets.

- Glass Installation: Glass panels are carefully fitted into the aluminum frames, ensuring a snug and secure fit.

- Surface Finishing: Frames undergo polishing, buffing, and anodizing for corrosion resistance and aesthetic appeal.

- Quality Inspection: Each finished product undergoes a detailed inspection to ensure it meets industry standards.

- Packaging and Dispatch: Completed products are carefully packed to prevent damage during transportation and prepared for delivery or installation.

Each stage requires precision, attention to detail, and strict adherence to safety and quality standards.

Cutting corners at any step can compromise the final product and your reputation.

Quality Control Measures

Quality isn’t just a box to tick—it’s a promise to your customers.

In the aluminum door and window industry, poor quality can result in safety hazards, costly repairs, and damage to your brand reputation.

Here’s how to ensure every product leaving your factory meets top-notch quality standards:

- Material Inspection: Check raw materials for defects or inconsistencies before production begins.

- In-Process Checks: Conduct quality checks during each stage of production to catch errors early.

- Final Inspection: Once products are assembled and finished, inspect them for alignment, durability, and finish quality.

- Compliance Testing: Ensure all products meet regional and international standards for safety and performance.

- Customer Feedback Loop: Encourage customers to provide feedback and use it to improve product quality continuously.

Investing in quality control systems and processes may seem costly initially, but it prevents expensive product recalls, enhances customer trust, and positions your brand as reliable.

Sales and Marketing Strategies

You’ve got your aluminum door and window manufacturing business up and running.

The next big challenge?

Getting your products into the hands of customers.

A strong sales and marketing strategy is your secret weapon to stand out in a crowded market.

In this section, we’ll cover branding, digital marketing, and traditional approaches to grow your business effectively.

Branding and Positioning

Your brand isn’t just your logo or tagline—it’s the experience customers have with your business.

A strong brand identity builds trust, sets you apart from competitors, and keeps customers coming back.

Here’s how to build a powerful brand:

- Professional Logo and Design: Invest in a clean, professional logo and consistent visual identity across all platforms.

- Clear Value Proposition: What makes your aluminum doors and windows special? Is it durability, innovative design, or eco-friendly production? Highlight this in your messaging.

- Customer Experience: Every interaction—from your website to your sales team—should reflect professionalism and reliability.

- Build Trust Through Testimonials: Showcase customer reviews and successful project case studies on your website and marketing materials.

Remember, customers don’t just buy doors and windows—they buy reliability, security, and style.

Position your brand as the go-to choice for quality and innovation.

Digital Marketing

In today’s world, if your business isn’t online, it might as well be invisible.

Digital marketing is an essential tool for reaching your target audience and driving sales.

Key digital marketing strategies include:

- Professional Website: Create a user-friendly website showcasing your products, pricing, and contact details. Optimize it for SEO so potential customers can find you on search engines.

- Social Media Presence: Platforms like Facebook, Instagram, and LinkedIn are excellent for showcasing your products, sharing customer stories, and engaging with your audience.

- Online Marketplaces: List your products on e-commerce platforms or industry-specific marketplaces to expand your reach.

- Content Marketing: Start a blog or share guides on aluminum door maintenance, design trends, or installation tips. It builds authority and attracts organic traffic.

- Email Campaigns: Keep customers updated with promotions, new product launches, and industry insights through newsletters.

Digital marketing isn’t a one-time effort—it’s an ongoing strategy.

Keep monitoring your analytics, refine your approach, and stay active online.

Traditional Marketing

While digital marketing dominates today’s landscape, traditional marketing still holds significant value—especially in industries like construction and manufacturing.

Effective traditional marketing strategies include:

- Trade Shows and Exhibitions: Participate in local and international trade fairs to showcase your products and network with potential clients.

- Brochures and Catalogs: Provide professionally designed brochures to clients, architects, and contractors for quick reference.

- Networking with Contractors and Builders: Build relationships with key players in the construction industry. A strong network can lead to repeat business and referrals.

- Outdoor Advertising: Use billboards or banners in strategic locations to build local brand awareness.

The best results often come from combining digital and traditional strategies.

For example, you could promote an upcoming trade show on your social media channels to maximize attendance.

Distribution and Logistics

Once you’ve secured orders, the next challenge is ensuring your aluminum doors and windows reach customers on time and in perfect condition.

Efficient distribution and logistics are the backbone of customer satisfaction and repeat business.

Delivery Channels

Your distribution strategy depends on your business model and target market.

Let’s explore the most common channels:

- Direct Sales: Sell directly to end-users, whether they’re homeowners or commercial clients. This model allows you to control the customer experience from start to finish.

- Wholesale Partnerships: Partner with wholesalers who can distribute your products to retailers or contractors. This approach helps you scale quickly without managing every sale individually.

- Retail Outlets: Set up your showroom or partner with established retail outlets to display your products for customers to see and feel.

- E-commerce Sales: Offer online purchasing options with reliable delivery services. This approach caters to customers who prefer digital convenience.

A combination of these channels often works best.

For instance, you might handle large commercial projects directly while using wholesalers for smaller regional markets.

Geographic Expansion

Once you’ve established a solid local presence, it’s time to think bigger.

Expanding into regional or even international markets can open up exciting growth opportunities.

Here’s how to plan your expansion:

- Market Research: Understand the demand, competition, and customer preferences in your target regions.

- Partner with Local Distributors: Collaborate with reliable local partners who understand the market and logistics landscape.

- Logistics Infrastructure: Ensure you have efficient shipping and delivery systems in place to avoid delays and damage.

- Compliance and Regulations: Different regions may have varying safety standards and legal requirements. Do your homework before entering new markets.

For international expansion, start small.

Test the waters with a few strategic markets before committing significant resources.

Pro Tip: Highlight your international capabilities in your marketing materials.

Being recognized as a global supplier can enhance your brand reputation.

Customer Service and After-Sales Support

Running an aluminum door and window manufacturing business isn’t just about producing high-quality products—it’s about building trust and long-term relationships with your customers.

Exceptional customer service and reliable after-sales support can set you apart from competitors and turn one-time buyers into loyal clients.

Customer Relationship Management (CRM)

Customer relationships don’t end after a sale—they’re just beginning.

A solid Customer Relationship Management (CRM) strategy helps you stay connected with your clients, anticipate their needs, and provide timely support.

- Centralized Customer Data: Use CRM software to store customer details, track purchase history, and schedule follow-ups.

- Personalized Communication: Tailor your communication—like sending thank-you emails, special offers, or maintenance reminders—to make customers feel valued.

- Quick Support System: Offer multiple support channels such as phone, email, and live chat to handle inquiries and complaints promptly.

Strong CRM practices build trust, increase repeat purchases, and encourage positive word-of-mouth recommendations. Happy customers are often your best marketers!

Warranty and Service Policies

Offering transparent and competitive warranty and service policies isn’t just about fixing problems—it’s about showing customers you stand behind your products.

- Clear Warranty Terms: Clearly state what your warranty covers (e.g., manufacturing defects, hardware issues) and the warranty duration.

- Hassle-Free Claim Process: Make it easy for customers to submit warranty claims without jumping through hoops.

- Maintenance Packages: Offer annual maintenance services to keep aluminum doors and windows in top condition.

When customers know you’ve got their back even after the sale, they’re more likely to choose your products over competitors’.

In short: Treat customer service as an ongoing commitment, not a one-time obligation.

Build relationships, communicate proactively, and stand by your products with solid warranties and support systems.

Sustainability Practices

Sustainability isn’t just a buzzword—it’s a necessity.

Today’s customers care about how products are made and their impact on the planet.

By adopting sustainable practices, your aluminum door and window business can reduce its carbon footprint, lower costs, and attract eco-conscious customers.

Eco-Friendly Manufacturing

Manufacturing processes can generate waste and emissions, but sustainable practices can minimize their environmental impact.

Here’s how:

- Material Recycling: Aluminum is 100% recyclable. Implement a recycling system to reduce waste and lower raw material costs.

- Energy-Efficient Equipment: Use energy-saving machinery to cut down on electricity consumption.

- Waste Management Systems: Properly dispose of or recycle industrial waste to prevent environmental harm.

- Sustainable Sourcing: Partner with suppliers who prioritize environmentally friendly practices.

Sustainability isn’t just good for the planet—it’s good for your bottom line.

It reduces costs and enhances your brand reputation.

Energy Efficiency

Aluminum doors and windows are naturally energy-efficient, making them a preferred choice for modern homes and buildings.

Highlight these benefits to appeal to environmentally conscious buyers:

- Thermal Insulation: Aluminum frames paired with energy-efficient glass help reduce heat loss in winter and heat gain in summer.

- Reduced Energy Costs: Energy-efficient doors and windows can lower utility bills significantly.

- Long Lifespan: Durable aluminum products reduce the need for frequent replacements, minimizing waste.

By emphasizing these benefits in your marketing and product materials, you’ll appeal to both residential and commercial customers looking to save energy and reduce costs.

In short: Embrace eco-friendly manufacturing processes and highlight the energy-saving benefits of your aluminum products.

Sustainability isn’t just a choice—it’s a competitive advantage.

Challenges and Risk Management

Every business faces challenges, and aluminum door and window manufacturing is no exception.

From market competition to operational risks, understanding these challenges and preparing for them can help you navigate hurdles and keep your business on track.

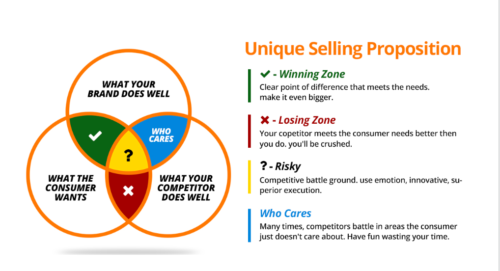

Market Competition

The aluminum door and window industry is competitive, with both large manufacturers and smaller players fighting for market share.

Standing out requires a mix of strategy, innovation, and quality.

- Unique Selling Proposition (USP): Identify what sets your business apart. Is it premium quality, customizable designs, or unbeatable customer service?

- Focus on Innovation: Offer modern designs, energy-efficient products, or smart home-compatible windows and doors.

- Strong Branding: Build a recognizable brand that customers associate with trust and reliability.

- Customer Loyalty Programs: Offer discounts or exclusive deals to repeat customers and referral clients.

By differentiating your products and maintaining high standards, you’ll secure your spot in the market—even against well-established competitors.

Operational Risks

Operational challenges can arise from supply chain disruptions, equipment malfunctions, or unexpected market shifts.

Here’s how to minimize these risks:

- Diversify Suppliers: Don’t rely on a single supplier for raw materials. Build relationships with multiple vendors to ensure a steady supply.

- Equipment Maintenance: Regularly service and inspect your machinery to avoid costly breakdowns and production delays.

- Buffer Stock: Keep a small reserve of essential raw materials to handle sudden supply disruptions.

- Market Adaptability: Stay informed about market trends and be prepared to adjust your product offerings if demand shifts.

Planning for risks doesn’t eliminate them, but it significantly reduces their impact on your business operations.

In short: Stay ahead of competition by focusing on your strengths and embracing innovation.

Mitigate operational risks with a proactive approach to supply chain management and production planning.

Future Growth Opportunities

The aluminum door and window industry isn’t just about meeting today’s demand—it’s about anticipating tomorrow’s trends.

As technology evolves and customer expectations shift, businesses that stay ahead of the curve will lead the market.

In this final section, we’ll explore opportunities for innovation, product development, and expansion strategies to future-proof your business.

Innovation and Product Development

Innovation isn’t just about creating flashy designs; it’s about solving real problems and adding value to your customers’ lives.

In the aluminum door and window industry, product development often focuses on improving energy efficiency, durability, and aesthetics.

Key Areas for Innovation:

- Smart Windows and Doors: Integrate advanced technologies like automated locking systems, motion sensors, and smart glass that can adjust transparency based on light or heat levels.

- Energy-Efficient Solutions: Invest in designs that improve thermal insulation, reduce energy consumption, and meet green building standards.

- Modern Aesthetics: Stay ahead of architectural trends by offering sleek, minimalist designs that align with contemporary building styles.

- Customization Options: Offer tailor-made products that cater to specific customer requirements, from unique sizes to custom finishes.

Why Innovation Matters:

Customers are no longer just looking for functional doors and windows—they want products that enhance their lifestyle, save energy, and align with modern architectural aesthetics.

By staying innovative, you’ll not only meet these expectations but also set your brand apart in a crowded market.

Innovation isn’t a one-time effort.

Continuously invest in research and development, attend industry expos, and stay updated with the latest technologies.

Your next big breakthrough might just be around the corner!

Expansion Strategies

Once your aluminum door and window business has a strong foundation, it’s time to think bigger.

Expansion doesn’t always mean opening new factories—it can involve strategic moves that allow you to grow smartly.

Here are two key approaches to consider:

- Franchising: If your business model is successful and replicable, franchising can be a powerful growth strategy. By allowing partners to operate under your brand, you can expand into new territories without the heavy financial burden of opening multiple outlets yourself. Franchising works best when your processes are standardized, and your brand has strong market recognition.

- Strategic Partnerships: Collaborate with construction companies, large developers, or even international distributors to expand your market reach. Partnerships can open doors to large-scale projects, government contracts, and international markets.

Other Expansion Tactics to Explore:

- Entering untapped regional markets with high construction activity.

- Diversifying your product line to include related offerings like aluminum railings or facades.

- Strengthening your e-commerce presence to reach a global audience.

Plan Before You Expand:

Expansion is exciting, but it requires careful planning.

Conduct thorough market research, understand the legal requirements of new regions, and ensure you have a reliable supply chain in place.

Conclusion

Starting an aluminum door and window manufacturing business offers immense potential in a growing market.

From understanding global trends and building a skilled workforce to embracing innovation and sustainability, every step plays a crucial role in long-term success.

With the right strategies, your business can thrive.

Ready to turn your vision into reality?

Take the first step today—plan strategically, invest wisely, and stay committed to delivering quality.

The aluminum industry is waiting for passionate entrepreneurs like you to make a mark.

Start your journey now and build a future-proof business!

FAQs About Aluminum Door and Window Manufacturing Business

1. Is the aluminum business profitable?

Yes, the aluminum industry is highly profitable, especially in sectors like aluminum door and window manufacturing. The industry benefits from the increasing demand for durable, energy-efficient materials. Recycled aluminum production also reduces costs and boosts profit margins, making it an eco-friendly and cost-effective choice for manufacturers.

2. How are aluminum doors and windows made?

Aluminum doors and windows are primarily crafted using aluminum profiles created through a process called extrusion. In this process, aluminum billets are heated to temperatures between 375°C to 500°C and forced through a shaped opening called a die. The resulting profiles are then cut, assembled, and fitted with glass and hardware to create finished products.

3. How much does it cost to make an aluminum window?

The cost of manufacturing aluminum windows depends on the window type and design. On average, the prices in India per square foot are:

- Casement Window: ₹175-300

- Tilt and Turn Window: ₹200-350

- Fixed Window: ₹125-200

- Sliding Window: ₹150-250

Costs may vary based on material quality, labor charges, and regional factors.

4. How big is the aluminum window market?

The global aluminum window profile market was valued at approximately US$ 750 million in 2021. With increasing demand for energy-efficient building solutions and ongoing urbanization, the market is projected to grow steadily through 2030, offering significant opportunities for manufacturers and suppliers worldwide.

5. What are the major factors driving growth in the aluminum door and window market?

Several factors are contributing to the growth of this market:

- Rising demand for energy-efficient and sustainable building materials.

- Increased construction activities in urban and residential sectors.

- Preference for aesthetic and modern architectural designs.

- Growth in commercial infrastructure projects worldwide.

By focusing on these trends and aligning your business strategy, you can tap into the growing opportunities in the aluminum door and window industry.

![Apro logo - 25 Types of Door Hinges and Their Best Uses [Dezember 2025] - APRO Apro logo](https://aprowin.com/wp-content/uploads/2024/08/Apro-logo.webp)

![A bifold glass door opens to a serene courtyard featuring a beautiful fountain at its center - 25 Types of Door Hinges and Their Best Uses [Dezember 2025] - APRO A bifold glass door opens to a serene courtyard featuring a beautiful fountain at its center](https://aprowin.com/wp-content/uploads/2024/10/A-bifold-glass-door-opens-to-a-serene-courtyard-featuring-a-beautiful-fountain-at-its-center.webp)

![Sunflower view through modern black aluminum window frame - 25 Types of Door Hinges and Their Best Uses [Dezember 2025] - APRO Sunflower view through modern black aluminum window frame](https://aprowin.com/wp-content/uploads/2024/10/Sunflower-view-through-modern-black-aluminum-window-frame.webp)

![Modern entrance featuring glass doors and awning for commercial projects - 25 Types of Door Hinges and Their Best Uses [Dezember 2025] - APRO Modern entrance featuring glass doors and awning for commercial projects](https://aprowin.com/wp-content/uploads/2024/10/Modern-entrance-featuring-glass-doors-and-awning-for-commercial-projects.webp)

![Stylish residential project showcasing modern architecture and a beautiful pool area - 25 Types of Door Hinges and Their Best Uses [Dezember 2025] - APRO Stylish residential project showcasing modern architecture and a beautiful pool area](https://aprowin.com/wp-content/uploads/2024/10/Stylish-residential-project-showcasing-modern-architecture-and-a-beautiful-pool-area.webp)

![APRO team showcasing professionalism in company showroom environment - Aluminum Door and Window Manufacturing Business Plan [2025] - APRO APRO team showcasing professionalism in company showroom environment](https://aprowin.com/wp-content/uploads/2024/11/APRO-team-showcasing-professionalism-in-company-showroom-environment-2048x1366.webp)

![APRO logo white - 25 Types of Door Hinges and Their Best Uses [Dezember 2025] - APRO APRO logo white](https://aprowin.com/wp-content/uploads/2024/07/APRO-logo-white.webp)