We deliver Stone Cladding Exterior Wall systems with project-specific stone selection, panel sizing, fixing design, and shop-drawing support for smooth installation.

We deliver Stone Cladding Exterior Wall systems with project-specific stone selection, panel sizing, fixing design, and shop-drawing support for smooth installation.

A stone cladding exterior wall is an outer façade finish where stone panels (natural or engineered) are attached to a building’s structure (often on a metal sub-frame) to create a durable, premium-looking exterior. The stone layer is usually non-load-bearing—it protects the building, improves appearance, and can support thermal/acoustic performance depending on the build-up.

Key Specifications:

Installing a Stone Cladding Exterior Wall requires precise detailing and workmanship to achieve a seamless façade appearance and reliable long-term structural performance.

Confirm substrate condition, levels, plumb lines, control points, and panel grid layout from drawings.

Repair the backup wall, ensure flatness/tolerances, and clean surfaces so anchors and membranes can perform properly.

Apply the approved membrane and install flashings at slab edges, openings, and transitions to manage water.

Mark fixing points and install anchors/brackets per load design, verifying embedment depth and pull-out requirements.

Erect vertical/horizontal rails, align to façade plane, and lock the frame with correct spacing and corrosion protection.

Install insulation boards, cavity barriers, and fire-stopping details to meet thermal and fire code targets.

Check stone IDs, finish, thickness, and edges; drill/kerf/undercut (as specified) and fit anchors or clips.

Install panels from bottom up, maintain joint width and level lines, and adjust for consistent reveals and movement joints.

Seal joints where required, confirm drainage paths, inspect alignment and fixings, and clean the façade for handover.

Stone façade system delivers a refined, timeless exterior for a wide range of projects, elevating both architectural character and long-term performance.

Common options include granite, limestone, sandstone, travertine, marble, and slate—selection depends on weather exposure, durability needs, and desired appearance.

Most stone façade systems are designed as water-managed assemblies (often rainscreen-style), relying on joints, flashings, membranes, and drainage—not just “sealed stone.”

They can. Insulation is typically installed behind the stone cladding to improve thermal performance while keeping the exterior stone finish intact.

Proper movement joints, correct anchoring, and suitable stone selection reduce cracking risk; staining can be minimized with correct detailing, drainage, and maintenance.

Routine maintenance includes periodic washing, joint/sealant checks, and spot treatment for stains; sealing may be recommended depending on stone porosity and exposure.

Provide elevations, panel layout, stone type/finish, project location, wind/load requirements, desired system type (rainscreen or direct-fix), and any thermal/fire targets.

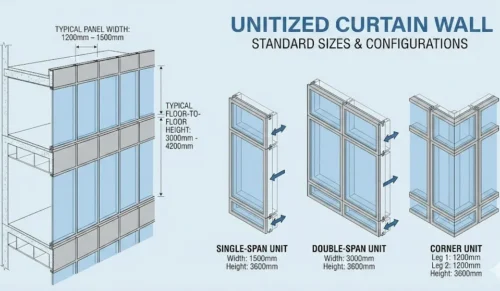

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

Standard unitized curtain wall sizes explained: module width/height, frame depth, IGU thickness, joint sizing, tolerances, and case-based sizing plans.

Learn curtain wall glass types and uses: IGU vs laminated vs tempered, Low-E benefits, safety needs, and spec tips for projects

Learn what glass is, how it’s made, and how to choose: tempered, laminated, IGU, Low-E, VLT/SHGC/U-value, plus PO spec tips.

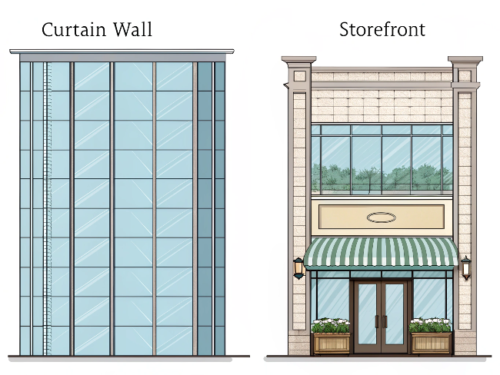

Learn its core definition, key components, performance metrics, drainage/weep details, and how it differs from curtain wall—so you can specify with confidence.

storefront vs window wall explained with clear pros/cons, costs, leak risks, and selection tips—use our decision framework to choose the right system today.

WhatsApp us