Aluminum Composite Panel (ACP) facade engineering and installation services, covering system design, custom module sizing, subframe detailing, finish selection, waterproofing, and on-site quality control for a clean, durable exterior.

Aluminum Composite Panel (ACP) facade engineering and installation services, covering system design, custom module sizing, subframe detailing, finish selection, waterproofing, and on-site quality control for a clean, durable exterior.

An aluminum composite panel (ACP) Exterior wall is a lightweight cladding sheet made by bonding two thin aluminum skins to a non-aluminum core (commonly polyethylene or a fire-retardant mineral-filled core). It’s widely used for building facades, signage, and soffits because it’s flat, easy to fabricate, and offers many finishes/colors, while providing good weather resistance and a clean, modern appearance.

Key Specifications:

Custom ACP exterior wall solutions tailored to your project—module sizing, joint layout, subframe detailing, profile options, and finish/color selection—engineered for clean aesthetics, reliable waterproofing, and fast installation.

Specify panel thickness, aluminum skin thickness, core type (FR/mineral/non-FR), and surface performance to meet durability and service-life expectations.

Customize panel dimensions, joint spacing, and façade module grids to match your elevation lines, openings, and installation method.

Choose PVDF/FEVE/PE coatings, anodized-look, brushed textures, or metallic finishes—color-matched to your RAL/Pantone requirement and project samples.

Engineer the ACP exterior wall to your local wind pressure requirements with appropriate sub-framing, fixing method, and panel reinforcement for safe performance.

Optimize panel build-up, backing materials, and cavity design to improve sound reduction—suitable for traffic-heavy and high-noise environments.

Select fire-rated cores and system detailing to meet required fire performance standards, with documentation support for approval and inspection.

ACP installation typically includes setting out, installing brackets and a leveled subframe, mounting the fabricated panels, then finishing joints and perimeter seals for a clean, weather-tight facade.

Confirm site dimensions, slab edges, and datum lines; mark façade grid, levels, bracket locations, and joint lines.

Fix anchors/chemical bolts and adjustable brackets to the structure; verify torque, pull-out capacity, and alignment.

Install vertical/horizontal aluminum sub-frames; plumb, level, and lock the façade plane to control lines.

Install insulation boards, vapor/air barrier membranes, and fire-stopping at floor lines per local code and project details.

Inspect ACP panel IDs, routing-folding edges, cut-outs, and protective film; ensure correct edge returns and reinforcement.

Fix panels using the specified system (cassette/hook-on, rivet/screw, or clip); keep joint widths uniform and maintain flatness.

Install gaskets/sealant, flashings, and drip edges; confirm drainage paths, clean surfaces, remove films, and complete final inspection.

Aluminum composite panel exterior wall provide a sleek look for multiple applications, enhancing both aesthetics and functionality:

An ACP façade uses sandwich panels made of two aluminum skins bonded to a core, installed on a sub-frame for cladding and architectural finishes.

ACP is lighter and often more cost-effective with good flatness; solid aluminum is typically more impact-resistant and can be easier to specify for certain fire requirements.

Common overall thicknesses include 3mm, 4mm, and 6mm. Final selection depends on wind load, panel size, flatness requirement, and fixing method.

Service life depends on coating grade, installation detailing, and environment (coastal/industrial). Higher-grade coatings and proper drainage/ventilation improve longevity.

Yes. ACP supports a wide range of solid colors, metallics, stone/wood looks, and custom matching (e.g., RAL/Pantone) depending on supplier capability.

Elevation drawings, panel layout/module size, finish/color, core/fire requirement, project location (wind zone), and desired performance targets (thermal/acoustic/water).

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

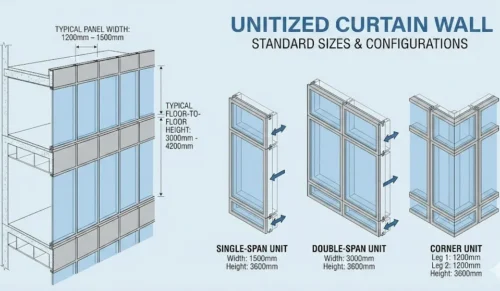

Standard unitized curtain wall sizes explained: module width/height, frame depth, IGU thickness, joint sizing, tolerances, and case-based sizing plans.

Learn curtain wall glass types and uses: IGU vs laminated vs tempered, Low-E benefits, safety needs, and spec tips for projects

Learn what glass is, how it’s made, and how to choose: tempered, laminated, IGU, Low-E, VLT/SHGC/U-value, plus PO spec tips.

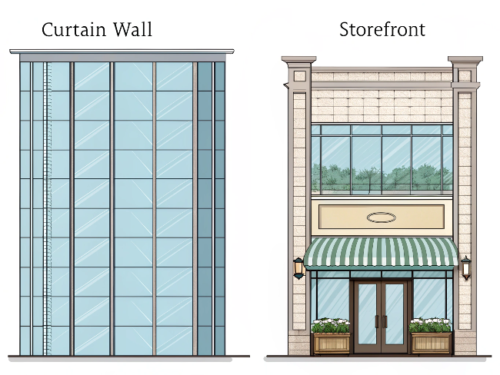

Learn its core definition, key components, performance metrics, drainage/weep details, and how it differs from curtain wall—so you can specify with confidence.

storefront vs window wall explained with clear pros/cons, costs, leak risks, and selection tips—use our decision framework to choose the right system today.

WhatsApp us