What is a Unitized Curtain Wall? Pros & Cons

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

In this phase, we collaborate with clients to understand their specific needs and finalize all design details, ensuring the product meets their expectations and fits perfectly.

In the material preparation phase, we gather all necessary materials and set up specialized machinery to ensure precise production.

Confirm window specifications to select appropriate aluminum profiles, glass, sealants, and accessories.

Choose high-quality materials tailored to project requirements for durability and performance.

Including aluminum double head cutting machines, corner cutting machines, and milling and drilling machines.

In this step, we shape and refine materials to exact specifications, preparing each component for smooth assembly and function.

Cut aluminum profiles to exact required lengths.

Drill holes and mill slots for hardware installation.

In the assembly stage, we bring together all components to create a sturdy, functional frame.

Profiles are joined into frames using various joints (45° or right-angle) and secured with screws, brackets, or welding for durability.

Glass panes are carefully set within frames, using gaskets or glazing beads to ensure a secure, airtight seal.

Essential hardware, including hinges, handles, and locks, is installed on the assembled frame.

Apro uses high-quality aluminum profiles, glass, sealants, and other essential accessories to ensure durability and performance.

The process begins with a client consultation to understand design preferences and measurements, followed by material selection, cutting, assembly, and quality control.

Apro follows a rigorous Quality Control process, which includes inspections at each stage, from material selection to final product checks, ensuring all doors meet high standards.

We use advanced equipment, including cutting machines, milling machines, and drilling machines, to ensure precision in every step of production.

Yes, Apro arranges transportation to the client’s site and offers professional installation services to ensure a seamless experience.

All products are carefully packaged with protective materials to prevent damage during transport, ensuring they arrive in perfect condition.

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

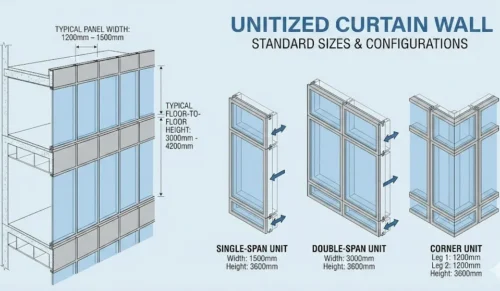

Standard unitized curtain wall sizes explained: module width/height, frame depth, IGU thickness, joint sizing, tolerances, and case-based sizing plans.

Learn curtain wall glass types and uses: IGU vs laminated vs tempered, Low-E benefits, safety needs, and spec tips for projects

Learn what glass is, how it’s made, and how to choose: tempered, laminated, IGU, Low-E, VLT/SHGC/U-value, plus PO spec tips.

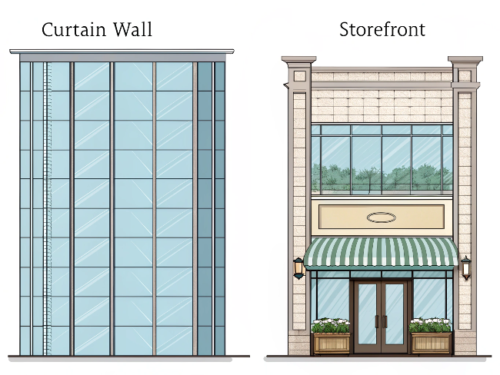

Learn its core definition, key components, performance metrics, drainage/weep details, and how it differs from curtain wall—so you can specify with confidence.

storefront vs window wall explained with clear pros/cons, costs, leak risks, and selection tips—use our decision framework to choose the right system today.

WhatsApp us