What is a Unitized Curtain Wall? Pros & Cons

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

Unitized curtain walls are prefabricated systems known for their efficiency, versatility, and quick installation, ideal for high-rise and commercial buildings.

Key Specifications:

Unitized curtain wall systems incorporate several key fittings for structural support and stability.

Secure unitized panels while allowing structural movement.

Restraining brackets control panel movement and prevent sway.

The installation of unitized curtain walls involves several critical steps for ensuring a secure and efficient setup.

Clear the area and ensure the foundation is level for proper installation.

Assemble the frame structure that will support the curtain wall panels.

Lift and attach the pre-assembled panels to the frame system.

Apply sealants to joints for weatherproofing and insulation.

Add braces to stabilize the system and secure panels tightly.

Conduct a final inspection to ensure everything is properly aligned and secure.

Unitized curtain walls are widely used in various building types due to their design flexibility and performance benefits:

A unitized curtain wall is a prefabricated system made of large panels that are assembled off-site and then installed on-site, offering efficiency and quick installation.

Unitized curtain walls provide faster installation, improved energy efficiency, reduced construction time, and enhanced structural performance, making them ideal for high-rise buildings.

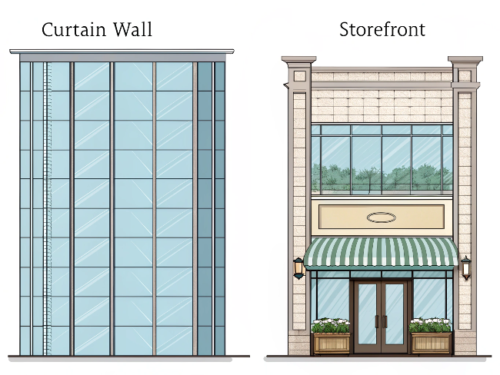

A curtain wall is a general term for an exterior cladding system, while a unitized curtain wall refers to a specific type of prefabricated system with pre-assembled panels for faster installation.

Stick-built curtain walls are assembled piece by piece on-site, while unitized curtain walls come in pre-assembled panels that are installed quickly, reducing construction time.

The cost of a unitized curtain wall depends on factors like material choice, building size, and design complexity, but generally, it can range from $50 to $150 per square foot.

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

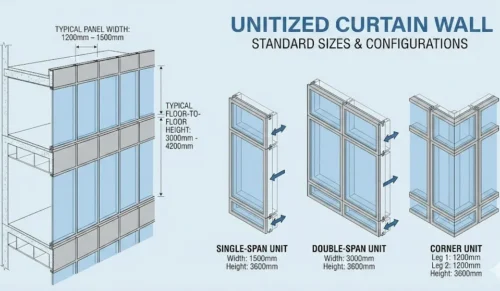

Standard unitized curtain wall sizes explained: module width/height, frame depth, IGU thickness, joint sizing, tolerances, and case-based sizing plans.

Learn curtain wall glass types and uses: IGU vs laminated vs tempered, Low-E benefits, safety needs, and spec tips for projects

Learn what glass is, how it’s made, and how to choose: tempered, laminated, IGU, Low-E, VLT/SHGC/U-value, plus PO spec tips.

Learn its core definition, key components, performance metrics, drainage/weep details, and how it differs from curtain wall—so you can specify with confidence.

storefront vs window wall explained with clear pros/cons, costs, leak risks, and selection tips—use our decision framework to choose the right system today.

WhatsApp us