What Is Glass?

💎 Glass Definition

Glass is a non-crystalline (amorphous) solid made by melting materials (most commonly silica-based) and then cooling them so they don’t form an ordered crystal structure. The atoms are “frozen” in a disordered arrangement—kind of like a liquid snapshot—but the material behaves as a solid.

🤔 Is it like a solid or like a liquid? — (common myth explained)

People sometimes say glass is a “supercooled liquid” that slowly flows (often pointing to old cathedral windows that are thicker at the bottom). In normal conditions, that’s a myth.

- At room temperature, glass is a solid. It has a rigid structure and does not measurably flow on human timescales.

- The “flow” idea comes from the fact that glass is amorphous, so its atomic arrangement resembles a liquid more than a crystal does.

- Old windows are thicker at the bottom mostly because of historic manufacturing methods and installation practices, not because the glass flowed downward over centuries.

What Is Glass Made Of?

🧪 Soda-Lime Glass (Most Architectural Glass)

Core ingredients (what each one does):

1. Silica (SiO₂): network former

Silica (usually from quartz sand) is the main structural backbone of most glass. It forms a strong, connected “network” of Si–O bonds that gives glass its basic hardness, chemical resistance, and transparency potential.

2. Soda ash (Na₂CO₃): lowers melting point

Pure silica melts at extremely high temperatures. Soda ash introduces sodium oxide (Na₂O) into the melt, which drops the melting temperature and makes the batch easier (and cheaper) to melt and form.

⚠️ Tradeoff: It can reduce chemical durability if not balanced with stabilizers.

3. Limestone (CaCO₃): improves durability

Limestone provides calcium oxide (CaO), which stabilizes the silica network. This improves water/chemical resistance and overall durability—basically helping offset the “softening” effect that soda introduces.

4. Dolomite / feldspar / alumina: tuning strength and workability

These are common “tuning knobs” in architectural glass recipes:

- Dolomite (CaMg(CO₃)₂): Adds MgO along with CaO, helping improve durability and sometimes viscosity control during manufacturing.

- Feldspar: Contributes alumina and alkalis; it can help adjust melting behavior and support a stable glass network.

- Alumina (Al₂O₃): Generally increases chemical durability and can improve mechanical properties, while also changing viscosity—useful for processing and strength tuning.

How Is Glass Produced?

🔥 Phase 1: Creation (The Hot End)

1. Batching

Measure and mix raw materials (sand/silica, soda ash, limestone, plus recycled glass/cullet).

2. Melting

Heat in a furnace until everything becomes a uniform molten glass.

3. Refining (de-bubbling)

Hold/condition the melt so bubbles and gases escape.

4. Forming

Shape the glass—architectural flat glass is usually made by the float process (molten glass spreads on molten tin).

❄️ Phase 2: Stabilization

5. Annealing (controlled cooling)

Cool slowly in a lehr to relieve internal stresses and prevent cracking.

🛠️ Phase 3: Processing & Inspection (The Cold End)

6. Finishing (optional)

Cut, edge-finish, temper/heat-strengthen, laminate, coat (e.g., Low-E), frost, etc.

7. Inspection + packing

Check for defects and package for shipping.

Factory Experience (1) — Production / QC Story

(Managing Edge Quality & Breakage Risk)

🏭 What we did in the factory

On one large run where we were fabricating glass units for a façade package, we noticed something that looks “small” on paper but becomes a big deal on site: edge damage was creeping up—tiny chips at corners and light “flea chips” along the cut edge.

The glass still looked fine when it was lying flat, but we know from experience that edges are where cracks love to start, especially during transport and installation.

🛠️ The Fix: Treating it as a Root-Cause Problem

We paused the run and implemented a systematic fix—not just a “touch-up and ship” approach:

- 🔹 Quarantine & Sort: Separated “exposed-edge” lites from “fully framed” lites (because the acceptance threshold is different).

- 🔹 Spec Check: Re-checked the edgework callout against the PO/spec (seamed vs ground vs polished) and visibility requirements.

- 🔹 Packing Upgrade: Adjusted handling + packing method: corner guards, no glass-to-glass contact, and “edge-first” protection on A-frames (abrasion during truck vibration was a contributor).

- 🔹 Earlier Checkpoints: Added a quick edge inspection right after cutting/edgework, rather than waiting for finished inspection.

🚩 What problem came up with the customer

The customer’s initial concern wasn’t “chips” as a technical term—it was practical:

“Will this crack during installation? And who owns the risk if it happens?”

✅ How we resolved it (with customer agreement)

We didn’t try to argue from theory. We proposed a simple, commercial solution:

- Exposed Edges: We upgraded the edgework to the agreed finish level and replaced anything outside the defined edge-zone acceptance.

- Concealed Edges: For glass fully covered by gaskets/frame, we confirmed (in writing) the allowable edge-zone criteria and provided photos so the rule was transparent.

- Schedule Protection: Agreed on a phased delivery plan: “clean lots first,” reworked lots shipped second.

Result: Tightened edgework, better packing, and clearer acceptance zones reduced installation risk and kept the project moving.

What Does Glass Do in a Building?

☀️ Let in daylight (and control it)

Glass brings natural light indoors, reducing reliance on artificial lighting. With coatings, tinting, frit patterns, or shading, it can also cut glare and balance brightness.

👁️ Provide views + visual connection

It links inside and outside—important for comfort, orientation, and the “feel” of a space.

🌡️ Manage heat (solar gain + heat loss)

Modern glazing isn’t just “transparent.” Low-E coatings, double/triple panes, gas fills, and thermal breaks help control:

- Heat escaping in winter

- Heat entering in summer

- Overall energy use and HVAC sizing

🌧️ Keep out weather

Glass and its seals form part of the building envelope—blocking wind, rain, and moisture while maintaining airtightness.

😌 Support occupant comfort

Good glazing improves:

- Thermal comfort: Less cold draft near windows, fewer hot spots.

- Visual comfort: Less glare, better light quality.

- Acoustic comfort: Sound-reducing laminated or multi-pane units.

🛡️ Provide safety and security

Depending on type, glass can be designed for:

- Impact resistance (tempered)

- Fall protection and retention (laminated)

- Forced-entry resistance (laminated + thicker builds)

🚒 Meet codes and fire/life-safety goals

Some glazing systems are engineered for fire resistance, smoke containment, or safe breakage behavior in hazardous locations.

🏛️ Enable aesthetics + identity

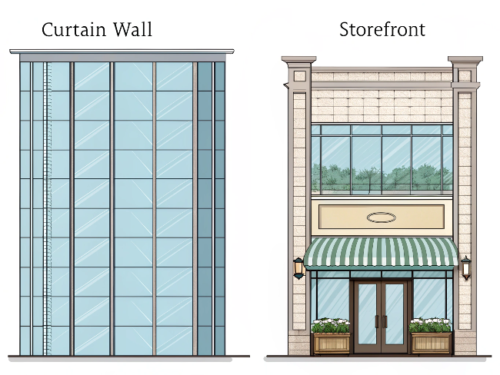

Facades, curtain walls, skylights, atriums, balustrades—glass shapes the building’s look, transparency, and “lightness.”

🏗️ Contribute structurally (sometimes)

While most glass is an infill material, specialty applications (fins, canopies, glass floors) use laminated/heat-treated glass as a true structural element.

Advantages vs. Disadvantages of Installing Glass

✅ Advantages of Installing Glass

- Daylighting: Brings in natural light, improving visual comfort and reducing daytime lighting demand.

- Views + openness: Makes spaces feel larger and more connected to the outdoors.

- Energy performance (with modern glazing): Double/triple glazing, gas fills, and Low-E coatings can cut heat loss in winter and reduce solar heat gain in summer.

- Thermal comfort near windows: Better glazing reduces cold drafts and “radiant chill” next to glass.

- Acoustic control (with the right build): Laminated glass and insulated glass units can significantly reduce exterior noise.

- Safety options: Tempered and laminated glass can improve impact resistance and safer break behavior.

- Design flexibility: Enables curtain walls, skylights, atriums, balustrades, and distinctive façades.

- Durability + low maintenance: Glass resists UV, moisture, and many chemicals; finishes don’t peel like paint.

⚠️ Disadvantages of Installing Glass

- Heat gain and heat loss risk: Poorly specified glass can overheat spaces in summer or leak heat in winter (especially single glazing).

- Glare: Large glass areas can cause uncomfortable brightness without shading, coatings, or frit/etching.

- Privacy concerns: Transparency can be a downside without layout choices, films, blinds, or translucent glazing.

- Bird collision risk: Reflective/clear glass can be hazardous to birds unless bird-safe patterns or coatings are used.

- Breakage sensitivity: Glass is brittle; edge damage, impacts, or thermal stress can lead to cracking if not designed/handled properly.

- Condensation potential: If surfaces get cold (or humidity is high), condensation can form—sometimes indicating thermal bridging or poor ventilation.

- Higher upfront cost for high performance: Energy-efficient, acoustic, security, or fire-rated glazing can be expensive.

- Cleaning and appearance management: Smudges, water spots, and façade cleaning can be ongoing costs—especially for high-rises.

Types of Glass (A Buyer-Friendly Classification Tree)

🟦 By Base Glass

- Float glass: The standard, flat “base” glass made by the float process—most other architectural glass types start here.

- Low-iron (ultra-clear): Float glass made with reduced iron content for higher clarity and less green tint—best when true color matters.

- Tinted glass: Glass colored in the melt (gray/bronze/green/blue, etc.) to reduce glare and solar gain and change façade appearance.

- Reflective glass: Glass with a reflective coating that increases exterior reflectance for solar control and/or privacy (with tradeoffs like glare and nighttime “mirror reversal”).

💪 By Strength and Safety

Annealed

Standard, slowly cooled glass. Cheapest and easy to cut, but breaks into large sharp shards and is the weakest option.

Heat-strengthened

Partially strengthened by heat treatment. Stronger than annealed and better for thermal stress, but it can still break into larger pieces (not the small “dice” of tempered).

Tempered

Fully heat-treated for higher strength and impact resistance. Breaks into small granules (safer break pattern). Must be cut/drilled before tempering.

Laminated (PVB/SGP/interlayers)

Two (or more) glass plies bonded with an interlayer. When broken, fragments stick to the interlayer—great for fall protection, overhead glazing, security, and acoustics.

- PVB: common, good all-around

- SGP (ionoplast): stiffer/stronger for structural edges, larger spans, and better post-break performance

- Other interlayers can target acoustics, UV, etc.

☀️ By Energy and Optics

Low-E glass (online/offline)

Low-emissivity coatings reduce heat transfer (especially radiant heat).

- Online (pyrolytic/hard coat): more durable, often a bit higher emissivity; can be used in tougher handling environments.

- Offline (sputtered/soft coat): typically better thermal performance, but more delicate (usually protected inside an IGU).

Solar control glass

Designed to reduce solar heat gain while keeping daylight—often via selective coatings and/or tint.

UV-blocking / anti-glare

- UV-blocking: protects interiors from fading (often boosted by laminates/interlayers).

- Anti-glare: reduces uncomfortable reflections/brightness via coatings, etching, or surface treatments.

Smart glass (electrochromic)

Tint changes on demand (switchable). Great for glare control and privacy strategies—higher cost and needs electrical integration.

🧊 By System Build-Up

IGU: double vs triple, gas fill, warm edge

Insulating Glass Unit (two or three panes with a sealed airspace).

- Double-pane: common sweet spot for cost/performance.

- Triple-pane: better insulation, thicker/heavier.

- Gas fill (argon/krypton): improves insulation vs air.

- Warm-edge spacers: reduce edge heat loss and condensation risk.

VIG: vacuum insulated glass

Very thin units with a vacuum gap for high insulation in a slimmer profile—useful for retrofits or where thickness is limited.

✨ Special-Function Glass

- Fire-rated: Engineered to resist fire and/or limit heat transfer for a rated time period—used in fire doors, partitions, and rated glazing systems.

- Acoustic laminated: Laminated glass with sound-damping interlayers to reduce traffic/urban noise—often paired with IGUs for best performance.

- Blast/ballistic/security: Multi-ply laminated builds (sometimes with polycarbonate) designed for forced-entry resistance or impact/blast performance—spec-driven and certification-heavy.

- Heated glass: Embedded conductive layer warms the glass to prevent fog/ice or add comfort near large windows—needs controls and electrical planning.

- Fritted/ceramic enamel: Patterns baked onto the glass for shading, glare control, privacy, and bird safety—also used for design/branding.

- U-profile glass: Channel-shaped cast glass used for translucent façades and partitions—diffuses light and can be part of modular wall systems.

Glass vs Plastic: Key Differences (Table + Quick Verdict)

Comparison Table (What Buyers Want to Know)

| Buyer question | Glass (architectural) | Plastic (typically acrylic/PMMA or polycarbonate/PC) |

|---|---|---|

| Raw materials | Mostly silica sand + soda ash + limestone (plus additives) | Mostly petrochemical polymers (some bio-based options exist, but less common in buildings) |

| Hardness / scratch resistance | High scratch resistance; stays clear longer with normal cleaning | Lower; scratches and scuffs easily (PC especially), often needs hard-coat for glazing use |

| Durability & UV aging | Very good long-term outdoor stability; doesn’t yellow | Varies: acrylic = good UV stability, polycarbonate = needs UV protection or it can yellow/haze over time |

| Sound insulation | Generally better at the same thickness (heavier = better sound blocking); laminated glass improves more | Generally worse at same thickness due to lower mass; multi-layer systems can help but aren’t typical “window-grade” |

| Thermal insulation | Single pane is poor; IGUs (double/triple + Low-E + gas) can be excellent | Single sheet can insulate slightly better than single glass due to lower conductivity; multiwall polycarbonate insulates well, but doesn’t match high-performance IGUs in clarity/air-tight detailing |

| Manufacturing cost | Higher material + processing cost; high-performance glazing adds cost | Often lower upfront for lightweight sheets; UV/hard-coated “glazing-grade” plastics can narrow the gap |

| Energy efficiency | Best overall toolbox: durable Low-E/solar control coatings, IGUs, warm-edge spacers | Can reduce heat gain with tints, but durable high-performance coatings are less common; multiwall panels help insulation but trade optical quality |

| Application range | Best for windows, curtain walls, doors, façades—especially where clarity, code compliance, and longevity matter | Best for skylights, canopies, greenhouses, impact-prone areas, lightweight enclosures, temporary/low-cost builds |

Key Performance Metrics When Buying Glass

(Not Just U-Value)

🌡️ Thermal Performance

U-value (Heat Transfer Coefficient)

Tells you how easily heat passes through the whole glazing assembly. Lower is better for insulation.

- Lower U = less winter heat loss, more stable interior temps.

- Compare apples to apples: Check center-of-glass vs. whole-unit U-value (frames/edges change the result).

R-value (Thermal Resistance)

Reciprocal of U-value. Higher is better for insulation.

⚠️ People often mix unit systems here, so ask which standard the spec uses.

SHGC (Solar Heat Gain Coefficient)

How much of the sun’s heat ends up inside. Lower means better shading.

- Lower SHGC reduces overheating/cooling loads (good for sunny façades).

- Note: This metric is huge for comfort—often more than U-value in hot climates.

👁️ Visual & Environmental Comfort

VLT (Visible Light Transmittance)

How much visible light passes through. Higher = brighter interiors.

⚠️ Common mistake: Picking high VLT without glare control causes uncomfortable brightness.

Air leakage, condensation, surface temperature

These are “comfort killers” if not handled.

- Air leakage: Depends mostly on the window system (seals/install), not just the glass.

- Condensation: Ask for condensation resistance data if you have high indoor humidity. Warm-edge spacers matter a lot here.

Lab Testing Experience (2) — Performance Validation Story

(Performance Validation & The “Fogging” Nightmare)

🧪 How we validate performance (and what we learned the hard way)

When a project is sensitive to comfort complaints or long-term IGU reliability, we push beyond marketing specs and validate performance using recognized test frameworks—especially around fogging resistance, seal durability, and moisture control.

In one validation cycle, we built a sample set of IGUs exactly as quoted (same spacer, sealant system, gas fill target, and coating placement), then ran an internal verification plan aligned with two widely used references:

- ASTM International — ASTM E2190 (insulating glass unit performance and evaluation).

- BSI / CEN — BS EN 1279-2:2018 (long-term method & requirements for moisture penetration).

⚠️ The issue we hit

The early samples didn’t “fail dramatically,” which is exactly why this matters. The warning sign was subtle: moisture control indicators were trending worse than expected at the edges.

On site, that’s the kind of thing that turns into the customer’s nightmare sentence later: “My IGUs are fogging.”

🛠️ What we changed (inside our process)

We treated it as a system problem (not one component) and tightened three areas:

- Seal discipline: We tightened the process window on sealant application and curing to stabilize edge seal consistency.

- Spacer + desiccant control: We reviewed desiccant loading and spacer handling to reduce moisture pathways.

- Coating + cleaning handling: We reinforced no-abrasive handling rules and clarified where coatings must sit (because wrong surface placement can create downstream condensation complaints).

🤝 How we negotiated the outcome with the customer

Here’s the part buyers care about: we didn’t just announce “process change.” We gave the customer two clear options:

Option A (performance-first): Accept the improved build (updated edge-seal controls + verified moisture targets) with a small lead-time shift.

Option B (schedule-first): Keep the original lead time, but accept stricter installation/handling constraints and a narrower warranty scope for edge-related issues.

Most customers choose Option A when it’s explained in plain language. The key is we made the tradeoff explicit—performance, schedule, and warranty are connected whether people say it out loud or not.

🔊 Acoustics: STC vs OITC

If you’re near a road, train, or flight path, low frequencies matter most.

- STC (or Rw): Good general indicator, but favors mid/high frequencies (voices).

- OITC: Better for traffic, aircraft, and street noise (weights lower frequencies).

- Tip: Consider laminated glass + asymmetric pane thicknesses to reduce resonance.

🛡️ Safety & Structure

Safety: Tempered vs. Laminated

Safety is about how the glass behaves when things go wrong.

- Tempered: Higher impact resistance; breaks into small granules.

- Laminated: Holds together after breakage; critical for overhead glazing, guardrails, and security.

- Ask what standard/classification it meets, not just “tempered” as a label.

Structure: Wind load, deflection, edge conditions

Structural performance is where “looks fine on paper” can fail in the field.

- Wind load + deflection set the required thickness.

- Panel size and aspect ratio matter a lot (big panes may need different support).

- For large façades: request structural calculations and confirm load assumptions.

How to Write Glass into a PO Specification

(Copy-Paste Framework)

📋 1. Product Name + Where Used

- Project: [Project name]

- PO Line Item: [Line item / tag]

- Location/Use: [Exterior windows / curtain wall / skylight / interior partition]

- Opening/Mark IDs: [W-101, CW-05, SK-02… per drawings]

- Drawing authority: [IFC set / Shop drawing set + revision/date]

🧊 2. Glass Make-up (Tempered/Laminated/IGU)

- Build type: [Monolithic / Laminated / IGU double / IGU triple / VIG]

- Safety treatment: [Annealed / Heat-strengthened / Tempered / Heat-soaked (if required)]

- Laminated interlayer: [PVB / acoustic PVB / SGP(ionoplast)] thickness: [ ] mm

- IGU panes: Outboard [ ] / Inboard [ ] (and middle pane if triple)

📏 3. Dimensions, Edgework & Fabrication

- Cut size (W × H): [ ] mm (or in) | Quantity: [ ]

- Lite schedule reference: [Attach lite schedule + drawing grid + mark IDs]

- Handing/orientation: [Exterior/interior face, top/bottom, frit location]

- Thickness + tolerances: Nominal [ ] mm each ply; total build-up [ ]; Tolerance [per standard: ASTM/EN/ISO + any tighter requirement]

- Edgework: [Seamed / Ground / Polished / Beveled] | Edge deletion: [Yes/No + width]

- Fabrication: [Holes / notches / slots / radius corners / shaped lites]

- Authority: “Shop drawing [rev/date] governs geometry; no substitutions.”

✨ 4. Coating Details & IGU Specs

- Coating type: [Low-E / solar control / reflective / AR] | Brand: [Manufacturer + product name]

- Surface position: Coating on Surface [2/3/etc.] (1=ext, 2=cavity outboard, 3=cavity inboard, 4=interior)

- Handling: “No razor scraping on coated surfaces; protect with [film/corner guards].”

- Cavity width: [ ] mm | Gas fill: [Air / Argon / Krypton] target [ ]%

- Spacer: [Warm-edge / aluminum] color: [ ]

- Seal system: Primary [PIB] / Secondary [silicone/polysulfide]

- Dew point requirement: ≤ [-40°C] (or per [ASTM/EN/ISO])

🎯 5. Performance Targets & Acceptance

Performance targets (basis: [NFRC/EN/ISO]):

- Thermal: U-value ≤ [ ] (specify “whole unit” or “center-of-glass”)

- Solar: SHGC ≤ [ ] ; VLT ≥ [ ]

- Acoustic: STC/Rw ≥ [ ] ; OITC ≥ [ ] (if needed)

- Safety: [Impact class / safety glazing standard]

- Structural: Design wind load: [ ] ; deflection limit: [ ]

Appearance acceptance criteria:

- Define viewing distance + lighting + zones (CVA vs Edge zone).

- State rejectables: scratches, digs, haze, roller wave, coating marks, etc.

- Reference standard: [ASTM C1036/C1048/C1172, EN 572/12150/14449] + project limits.

📦 6. Documents, Traceability & Warranty

- Documents: Compliance certificates (tempering, lamination, IGU), material traceability labels, coating care guide.

- Packaging: A-frames, edge/corner protection, no glass-to-glass contact, weather protection.

- Labeling: Mark ID, orientation arrow, coating surface, weight, “THIS SIDE OUT”.

- Receiving inspection: [48/72] hours window; concealed damage rules; photo documentation.

- Warranty term: [ ] years from [delivery/substantial completion].

- Defect definitions: Visible condensation (IGU), adhesion/corrosion (coating), delamination/bubbles (laminated).

- Claim process: Notice period + required evidence + replacement scope + freight.

📝 A Ready-to-Use PO Example (Fill-in Template)

Exterior window IGU example

Item: Exterior window IGU – [W-101 to W-135]

Build: 1″ (25 mm) IGU: 6 mm tempered outboard / 16 mm cavity argon / 6 mm laminated inboard (3+3 mm with [1.52 mm PVB])

Coating: Low-E [product code] on Surface 2.

Spacer: Warm-edge [type/color]. Primary seal PIB; secondary silicone.

Performance: U ≤ [ ] W/m²·K; SHGC ≤ [ ]; VLT ≥ [ ].

Edgework: Seamed edges; edge deletion [yes/no] [width].

Fabrication: Per shop drawings [rev/date]. No field drilling.

Acceptance: Appearance per [standard] + project limits.

Warranty: IGU seal failure [ ] years; coating [ ] years.

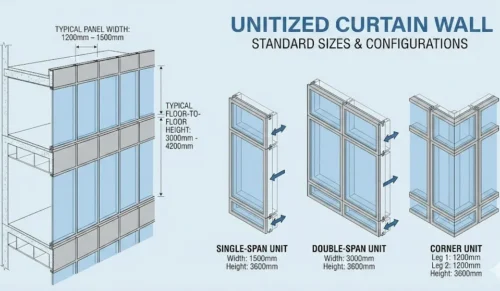

Curtain wall IGU example

Item: Curtain wall IGU – [CW-01 gridline A–D]

Build: [ ] mm IGU: Outboard [HS/Temp] [ ] mm + cavity [ ] mm [argon] + inboard [ ] mm [HS]

Coating: Solar control Low-E [product] on Surface [2/3]; color target [neutral/gray].

Structural: Design wind load [ ] Pa; deflection limit [ ]; glass thickness confirmed by sealed calc.

Edge conditions: Bite/edge cover per system: [ ] mm min.

Acceptance: Roller wave/optical distortion limits per [standard] + mockup approval.

Documents: Include calc summary + IGU certification + traceable labels.

Skylight laminated IGU example

Item: Skylight laminated IGU – [SK-01] (overhead glazing)

Build: IGU: Outboard tempered [ ] mm / cavity [ ] mm [argon] / Inboard laminated [ ]+[ ] mm with SGP [ ] mm (for post-break retention)

Coating: Low-E on Surface 2 (protected in cavity).

Safety: Overhead glazing requirement: laminated inboard, post-break retention required.

Acceptance: No lamination edge delam in CVA; stricter limits for bubbles/haze.

Handling: Protect coated surfaces; no suction cups on coated face unless approved.

How to Choose Glass by Application

(Fast Decision Section)

🏠 Exterior Windows (Residential/Commercial)

Recommended build-ups (by climate):

- Cold / heating-dominant: Double-pane IGU with Low-E + argon, warm-edge spacer. Consider triple-pane where comfort/condensation is critical.

- Mixed climates: Double-pane IGU with Low-E tuned for balance (moderate SHGC), argon fill, warm-edge.

- Hot / cooling-dominant: Double-pane IGU with solar-control Low-E (lower SHGC), argon; consider tinted/solar-control glass if glare/overheating is a problem.

- Noisy streets: IGU + laminated interior pane (acoustic interlayer if needed) and/or asymmetrical thickness (e.g., 6 mm out / 8.8 mm in).

What to prioritize:

- U-value: Comfort + heating/cooling load (crucial in cold climates).

- SHGC: Overheating control (crucial for south/west exposures).

- Condensation: Warm-edge spacer + good frame; ask for surface temp data if humidity is high.

- Acoustics: Prioritize OITC and laminated glass; STC alone can mislead.

🏢 Curtain Wall and Façade

Large lite risks (distortion, heat build-up, edge quality):

- Optical distortion: Big panes show roller wave/anisotropy more; mockups matter.

- Thermal stress: Darker tints, partial shading, and spandrel conditions heat unevenly → higher break risk (heat-strengthened/tempered often needed).

- Edges matter more: Chips/scratches at edges become crack starters—specify edgework and handling.

Coating consistency and color control:

- Specify one coating product (and approved alternates) to avoid panel-to-panel mismatch.

- Set color/reflectance tolerances (approval via mockup under daylight + night conditions).

- Lock down coating surface position and edge deletion requirements early.

☀️ Skylights and Canopies

Heat stress + safety rules of thumb:

- Assume higher thermal stress (sun + airflow differences + partial shading).

- Safety rule: Overhead glazing should be laminated on the interior side for retention (even if the outer pane is tempered).

- Manage solar gain/glare: Skylights can overheat spaces fast without a strategy.

Typical recommended configuration:

- Tempered outer pane (impact + weather exposure)

- IGU cavity with argon + warm-edge (if insulated)

- Laminated inner pane (post-break retention; consider SGP if structural)

- Low-E on a protected cavity surface (commonly Surface 2).

🧱 Glass Railings/Guardrails

Post-break safety (why laminated matters):

Railings must stay safe after breakage. Laminated glass holds fragments together, maintains a barrier longer, and reduces fall risk compared with monolithic tempered (which can “disappear” when shattered).

PVB vs SGP for structural performance:

- PVB: Common, cost-effective, good clarity; can be softer, with more deflection under load.

- SGP (ionoplast): Stiffer + stronger, better edge/structural behavior and better post-break performance—preferred for freestanding systems.

🚪 Interior Partitions/Doors

Tempered vs laminated selection logic:

- Tempered: Great default for doors/partitions where impact safety is the main need and cost matters.

- Laminated: Choose for sound control, security, or where broken glass must remain in place (e.g., higher-end offices, schools).

Privacy + budget options:

- Lowest cost: Clear tempered + blinds/films.

- Built-in privacy: Frosted/etched glass or patterned films.

- Best value: Laminated with a translucent interlayer or ceramic frit patterns (hides fingerprints better).

Standards & Data Reference Insert (3)

(Place under H2: How to Write Glass into a PO Specification inside “Performance targets + test methods”)

When we write performance into a PO, we always recommend anchoring it to a recognized test reference and a recognized data source—so suppliers can’t quietly swap a build-up and still claim it’s “equivalent.”

For IGU durability/fogging/seal performance, many specs reference ASTM’s insulating glass evaluation framework (ASTM E2190).

For moisture penetration / dew-point related requirements in insulating glass, EN 1279-2 is a commonly used reference within the EN 1279 family.

For comparable product energy ratings data, we often tell buyers to confirm U-factor/SHGC/VT through an industry certification data source like the NFRC Certified Products Directory, rather than relying on brochure numbers.

(That NFRC directory reference is especially helpful when you’re comparing options across brands and need consistent rating rules, not hand-picked “best case” numbers.)

Installation Case Insert (4) — “Our Project Example”

(Eagle Mall, Iraq: When glass selection meets real site constraints)

🏗️ The Real-World Context

A good example is our Eagle Mall curtain wall project in Iraq, where the building faced extended extreme heat, high-elevation installation risk, and limits in locally available safety systems.

🚩 The problem we had to solve

The client’s concerns weren’t abstract performance metrics—they were practical:

- Extreme Environment: Heat exposure can stress façade materials, seals, and glazing systems over time.

- Energy Needs: The project needed strong thermal insulation to reduce heat transfer and keep indoor spaces more stable.

- Site Logistics: Installation involved large panels at height, and local scaffolding/safety equipment didn’t fully match the project’s risk profile.

🛠️ What we did (and how we worked with the customer)

We treated this as a combined design + execution problem:

- System Design: We designed a high thermal-insulation curtain wall system using multi-layer profiles and insulated glazing to reduce heat transfer.

- Material Selection: We selected heat-resistant materials (profiles, sealants, and hardware) aimed at stable performance under constant heat exposure.

- Integrated Safety: We supplied integrated scaffolding and safety protection systems tailored for high-level façade work so installation could proceed safely even while handling large panels.

- Coordination: We coordinated design → production → staged delivery → installation support so site work stayed aligned with what was actually being fabricated.

🤝 The negotiation moment (what we agreed with the client)

The key “agreement point” was safety and sequencing.

Because local safety systems were limited, we aligned with the client on a plan where safety equipment and working platforms were treated as part of the façade scope, not an afterthought. That allowed the team to keep installation controlled and keep schedule risk down.

✅ Result

The project outcome emphasized stable façade performance under heat and controlled installation at height, meeting performance and schedule expectations.

Conclusion

(Turning Risk into Reliability)

💎 The Value of Intentional Specification

Glass is one of the few building materials that can deliver daylight, views, weather protection, safety, and energy control at the same time—but only when it’s specified intentionally.

✅ The Right Workflow

- Start with the application: (Window, façade, skylight, railing, partition).

- Select the right build-up: (Monolithic vs Laminated vs IGU).

- Tune performance with key metrics: U-value/R-value, SHGC, VLT, condensation resistance, acoustics, safety class, and structural capacity.

⚠️ In Practice: “Best” ≠ “Fanciest”

The “best” glass is rarely the most expensive option. It is the one that matches:

- Your climate & orientation

- Comfort needs

- Code requirements

- Your budget

…while being clear about coatings, edge conditions, tolerances, and acceptance criteria.

🚀 Get those details right, and glass stops being a risk item and becomes a reliable, high-performance part of the building envelope.

FAQ

(Common Glass Questions & Myths)

🛡️ Tempered vs laminated: which is safer?

Depends on the hazard.

- Tempered is safer for impact because it breaks into small granules.

- Laminated is safer for fall protection/overhead/security because it stays together after breaking.

- For skylights and railings, laminated is usually the “safer-safe.”

⚡ Does Low-E always save energy?

Not automatically. Low-E helps, but the “win” depends on climate, orientation, SHGC, and the whole window system (frame + installation). A mismatched Low-E (wrong SHGC for your sun exposure) can reduce comfort or increase cooling load.

🧊 Double vs triple glazing: when is triple not worth it?

Triple often isn’t worth it when:

- The climate is mild.

- The building isn’t heavily heated/cooled.

- Frames/air leakage dominate performance anyway.

- Weight, thickness, and cost create design headaches.

Triple shines in cold climates, very quiet/comfort-driven projects, or where condensation risk is a big concern.

🌫️ Why do IGUs fog up—always quality issue?

Fog between panes usually means the seal failed (moisture got in). That can be a manufacturing defect, but it can also be caused by installation damage, edge impacts, sealant incompatibility, extreme thermal cycling, or drainage issues in the frame/system. Not every fogging case is purely “factory fault.”

🧮 How do I convert U-value and R-value?

In the same unit system, it’s simple: R = 1 / U and U = 1 / R.

⚠️ The common trap is mixing systems (SI vs imperial). If your spec sheets use different units, convert units first—then invert.

🔊 Is thicker glass always better for sound?

No. Thickness helps because mass blocks sound, but sound control is about the whole build:

- Laminated interlayers (especially acoustic).

- Wider air gaps in IGUs.

- Asymmetrical pane thickness (reduces resonance).

- Airtight frames and seals.

For traffic noise, ask for OITC, not just STC/Rw.

💥 Why does tempered glass “spontaneously” break?

It can be triggered by:

- Nickel sulfide inclusions (rare, but real).

- Edge chips/scratches that grow over time.

- Thermal stress from partial shading or hot spots.

- Point loads from tight gaskets or hardware.

Heat-soak testing can reduce (not eliminate) inclusion-related risk.

☀️ Can glass block 100% UV?

Standard clear glass blocks some UV but not all. To get near-total UV protection, you typically need laminated glass with a UV-blocking interlayer and/or specialty coatings. “100% UV” claims depend on the UV range specified (UVA vs UVB), so ask what wavelengths the data covers.

🏠 What’s most important for skylight glass?

Two big priorities:

- Safety retention: Laminated inner pane so it stays in place if it breaks.

- Solar/thermal control: Skylights can drive overheating and glare fast—tune SHGC and shading, and use a protected Low-E coating (usually inside the IGU cavity).

🌊 Coastal/high-pollution: which coatings and maintenance rules?

Coastal salt and pollution increase the risk of surface corrosion and staining. Practical rules:

- Prefer coatings that are protected inside an IGU (don’t expose soft coatings).

- Use manufacturer-approved cleaners only; avoid harsh abrasives.

- Rinse more often (salt film is the enemy).

- Detail for drainage and avoid water traps at edges/spacers.