What is a Unitized Curtain Wall? Pros & Cons

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

An aluminum panel exterior wall is an exterior cladding system where aluminum panels are installed on a supporting frame or substrate to form the building’s outer skin. It’s typically non-structural (non-load-bearing)—the building’s structure carries the loads—while the aluminum panels provide weather protection, a finished architectural appearance, and optional insulation/acoustic performance.

| Category | Test Item | Test Content | Technical Requirements |

|---|---|---|---|

| Geometry Size | Length and Width Dimensions | — | ≤ 2000mm: allowable deviation ±1.0mm > 2000mm: allowable deviation ±1.5mm |

| Geometry Size | Diagonal Line | — | ≤ 2000mm: allowable deviation ±2.0mm > 2000mm: allowable deviation ±3.0mm |

| Geometry Size | Planeness | — | Allowable deviation ≤ 1.5mm/1.5m |

| Fluorocarbon Coating | Average Dry Film Thickness | — | Two-coat > 30μm Three-coat > 40μm Four-coat > 55μm |

| Fluorocarbon Coating | Chromatism | — | Color difference testing with a colorimeter: ΔE < 2NBS |

| Fluorocarbon Coating | Glossiness | — | Error of limit value ± 5 |

| Fluorocarbon Coating | Pencil Hardness | — | ≥ 1H |

| Fluorocarbon Coating | Dry Adhesion | — | Grid drawing method, 100/100, Reach level 0 |

| Fluorocarbon Coating | Impact Resistance (Frontal Impact) | — | 50kgf·cm (490N·cm), No cracks and no paint peeling |

| Fluorocarbon Coating | Chemical Resistance | Resistant to hydrochloric acid | 15 minutes of intravenous drip, no bubbles |

| Fluorocarbon Coating | Chemical Resistance | Resistant to nitric acid | Color change: ΔE < 5NBS |

| Fluorocarbon Coating | Chemical Resistance | Resistant mortar | There was no change for 24 hours |

| Fluorocarbon Coating | Chemical Resistance | Resistant Detergent | There were no bubbles or peeling after 72 hours |

| Fluorocarbon Coating | Corrosion Resistance | Moisture-resistant | 4000 hours, Reach GB1740 Level 2 or above |

| Fluorocarbon Coating | Corrosion Resistance | Salt spray resistance | 4000 hours, Reach GB1740 Level 2 or above |

| Fluorocarbon Coating | Weather Fastness | Colour fading | Ten years later, ΔE ≤ 5NBS |

| Fluorocarbon Coating | Weather Fastness | Chalking | Ten years later, GB1766 level 1 |

| Fluorocarbon Coating | Weather Fastness | Luster retention | Ten years later, retention > 50% |

| Fluorocarbon Coating | Weather Fastness | Film thickness loss | Ten years later, Film thickness loss < 10% |

Design a welcoming façade with a aluminium panel facade—clean lines, solid structure, and tailored glazing for bright, open entrances.

Customize height, width, and module layout to match your opening and façade grid—available in fixed, operable, or sliding configurations.

Customize perforation patterns, hole sizes, and open-area ratios to control daylight, ventilation, and visual privacy—while matching your façade geometry.

Specify profile sections, finishes, and colors to meet structural requirements and deliver the exact look your project demands.

Installing a Aluminum Panel Exterior Wall requires precision for seamless design and optimal structural performance.

Verify substrates, slab edges, and datum lines; mark façade grid, levels, and bracket locations to control alignment.

Fix anchors/chemical bolts and adjustable brackets to the structure; check spacing, torque, and pull-out requirements.

Install vertical mullions/rails and secondary members; plumb and level to form a stable plane for panel mounting.

Place insulation boards, air/vapor barrier (if specified), and fire barriers at floor lines; seal gaps per project details.

Confirm panel ID, dimensions, finish, edges, and cut-outs/perforations; keep protective film on and avoid surface damage.

Hang panels using the specified fixing method (hook-on/clip/screw/rivet); maintain consistent joint width and panel flatness.

Install gaskets/sealant, flashings, and drip edges; ensure drainage paths and ventilation cavities remain unobstructed.

Check alignment, fasteners, joint uniformity, and water-tight detailing; remove film, clean surfaces, and complete handover records.

A Aluminum panel exterior wall offers a sleek and modern appearance for various applications, enhancing both the aesthetics and functionality of the structure.

Aluminum panel systems are opaque cladding (often with insulation behind), while glass curtain walls are transparent glazing systems focused on daylight and views.

Yes. Perforation patterns, hole sizes, and open-area ratios can be customized for shading, ventilation, privacy, and façade texture—while still meeting structural needs.

Typical aluminum panel thickness is chosen based on wind load, panel size, and flatness requirements. Larger panels and higher wind zones usually require thicker panels or reinforcement.

Common options include PVDF/FEVE coating, powder coating, anodized-look, brushed, and metallic finishes, with custom color matching (e.g., RAL/Pantone) available.

Most aluminum panel façades work as a rainscreen: water is managed by joints, flashings, gaskets/sealants, and drainage paths rather than fully “sealed” panels.

Lead time varies by finish, perforation complexity, and quantity. Shop drawings approval and sample confirmation usually impact the schedule the most

Elevation drawings, panel layout/module size, project location (wind zone), finish/color, perforation requirements, insulation/fire targets, and preferred installation method.

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

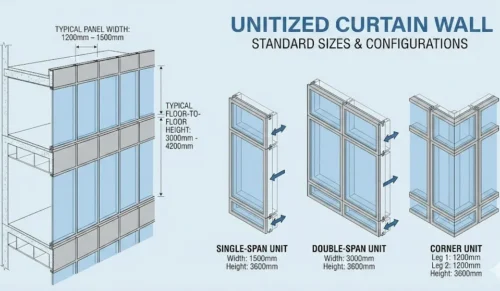

Standard unitized curtain wall sizes explained: module width/height, frame depth, IGU thickness, joint sizing, tolerances, and case-based sizing plans.

Learn curtain wall glass types and uses: IGU vs laminated vs tempered, Low-E benefits, safety needs, and spec tips for projects

Learn what glass is, how it’s made, and how to choose: tempered, laminated, IGU, Low-E, VLT/SHGC/U-value, plus PO spec tips.

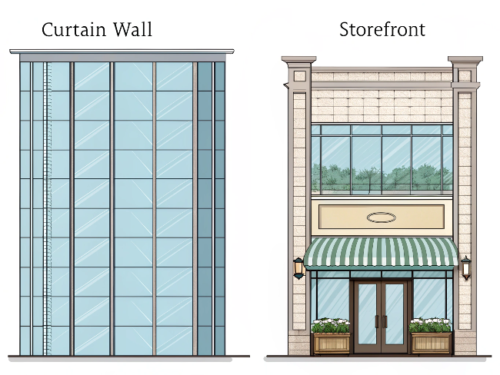

Learn its core definition, key components, performance metrics, drainage/weep details, and how it differs from curtain wall—so you can specify with confidence.

storefront vs window wall explained with clear pros/cons, costs, leak risks, and selection tips—use our decision framework to choose the right system today.

WhatsApp us