🌍 Global Sourcing: A Strategic Necessity

Sourcing building materials globally is no longer a trade secret; it is a necessity for modern construction competitiveness. However, importing complex building envelopes—specifically curtain wall systems—requires more than just finding a supplier on Alibaba. It requires a strategic partnership.

🏗️ Manufacturer’s Insight

As a curtain wall manufacturer with over 10 years of experience, owning our own aluminum extrusion lines and processing facilities, I have seen every side of this industry.

I have seen developers save 40% on their budget while achieving award-winning aesthetics.

I have seen contractors face shattered glass or dimensions drifting by millimeters, halting installation for weeks.

This guide is not just theory. It is a compilation of best practices for overseas curtain wall procurement, designed to help you navigate the China curtain wall supply chain for contractors without the headaches. Whether you need a high-performance unitized curtain wall for a high rise, a flexible stick-built curtain wall, or a bespoke spider system, the principles of risk control remain the same.

⏱️ 60-Second Judgment: Is Your Project Suitable for Importing?

Before we dive into the “how,” let’s address the “if.” Not every project is a candidate for cross-border procurement. Importing requires lead time and coordination.

✅ Which Projects Have the Highest Success Rate?

Generally, projects with a planned lead time of 4-6 months and a certain scale benefit most.

- ✔High-Rise Commercial Buildings: Where unitized curtain wall repetition offers massive economies of scale.

- ✔Large Residential Complexes: Using standardized stick-built curtain wall or window wall systems.

- ✔Luxury Hotels & Event Spaces: Where custom aesthetics (like the Nuvo Event Space project we managed) require high-end fabrication that would be cost-prohibitive domestically.

- ✔Public Infrastructure: Airports or stations requiring massive volumes of glass and aluminum.

🛑 When NOT to Source Overseas (3 Red Flags)

If your curtain wall procurement timeline allows less than 3 months from design to site delivery, domestic sourcing is safer. Sea freight and customs take time.

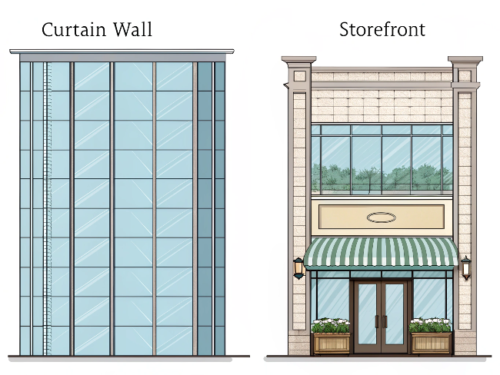

If you only need 50 sqm for a storefront renovation, the logistics costs (LCL shipping, port fees) will eat up your product savings.

If your architectural drawings are still “Napkin Sketches,” you cannot get an accurate quote. You need a clear curtain wall scope of work definition.

📋 The 6 Key Items You Need Before You Start

- [ ] Architectural Elevations and Floor Plans (CAD/PDF)

- [ ] Wind Load / Structural requirements (kpa or psf)

- [ ] Thermal performance targets (U-value, SHGC)

- [ ] Visual requirements (Glass color, profile finish)

- [ ] Project Schedule (When is the crane coming down?)

- [ ] Budget Constraints (Target price per sqm/sqft)

💡 One-Sentence Reminder: The Hybrid Solution

If you have a strict local union installation requirement but a tight material budget, consider buying the turnkey curtain wall package from China (materials + fabrication) but utilizing a local team for the install—we call this “supply only with tech support.”

🌏 Why Do More Projects Choose to Import Curtain Wall from China?

Industry Insight: According to a 2023 industry whitepaper on Global Construction Materials Flow, China accounts for over 60% of the world’s aluminum extrusion and architectural glass production. The supply chain density is unmatched.

✅ Core Advantages: Cost, Capacity, and Lead Time

1. Cost

You aren’t just saving on labor. You are saving on the supply chain. Because our factory integrates aluminum curtain wall profile alloy grade specification production (extrusion) with assembly, we cut out the middleman margins on raw aluminum.

2. Capacity

A sourcing unitized curtain wall from China strategy means accessing factories that can churn out 1,000+ panels a week.

3. Flexibility

We don’t just push Unitized systems. If your building has complex geometries, we can supply spider fittings, hidden frames, or visible frame stick systems. We manufacture what fits the building, not just what fits a single machine.

🏢 Target Project Types

- • Commercial Complexes: High ROI on thermal performance upgrades.

- • Hotels: Benefit from high-end acoustic glass options.

- • Apartments: High volume of repetitive window wall units.

- • Office Towers: The classic use case for unitized panels.

⚠️ The 4 Real Risks You Need to Worry About

If you plan to buy curtain wall from China for commercial projects, you must mitigate these four specific risks:

The risk isn’t usually “bad aluminum.” It’s “inconsistent assembly.” Does the sealant application vary from shift to shift? Is the thermal break insertion uniform?

🛡️ Mitigation: A strict curtain wall quality control plan for overseas manufacturing.

Does the glass meet your local safety code? Is the coating AAMA 2605 compliant?

🛡️ Mitigation: Curtain wall laboratory test report review checklist and ensuring strict adherence to standards like ASTM or EN.

The “Lost in Translation” effect usually happens during design changes.

🛡️ Mitigation: A rigorous facade change order process for curtain walls and clear revision controls.

Can your site handle a 40HQ container? Are the crates designed for safe unloading?

🛡️ Mitigation: Detailed curtain wall container loading plan and site unpacking and handling guide.

📝 Step 1: How to Clarify Project Requirements Before Inquiry

💡 “A vague inquiry gets a vague price. To get a professional proposal, you need a professional curtain wall RFQ checklist.”

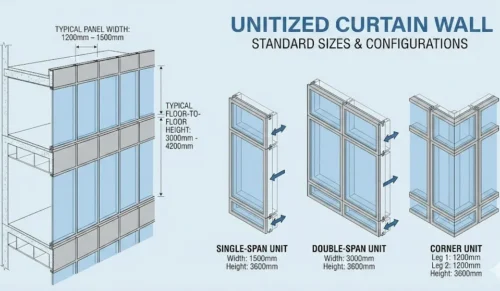

1. Lock in Curtain Wall System Type

First, understand what you are buying. Check our Curtain Wall Type Guide.

- 🏢 Unitized: Best for high-rise, fast enclosure, high labor costs onsite.

- 🏗️ Stick-Built: Best for low-rise, complex shapes, or limited crane access.

Note: Sourcing stick-built from China saves on material but increases site labor. - 🕷️ Point-Fixed (Spider): For lobbies/podiums requiring maximum transparency.

If Schedule is #1 → Pre-glaze in factory (Unitized).

If Budget is #1 → Use standard systems over custom dies.

2. Dimensions & Design Data Required

Your tender package must include these specific inputs:

📐 Architectural / Structural

- Floor-to-floor height: (Mullion strength)

- Slab edge conditions: (Anchor design)

- Live/Dead load deflection: (Movement accommodation)

🖼️ Facade / Site

- Module width: (e.g., 1200 vs 1500mm – affects waste)

- Transitions: (Roof/Ground connections)

- Install Method: (Crane vs Monorail → Lifting lugs)

3. Writing Function & Performance Specs

Don’t just say Good quality. Be specific to avoid disputes.

- 💨 Wind Load: Specify in kPa or PSF (e.g., +2.0/-2.0 kPa Serviceability).

- 💧 Water Tightness: Specify test pressure (e.g., 720 Pa static).

- 🔥 Thermal: U-value (Whole system, not just center of glass).

- North America: ASTM/AAMA (e.g., AAMA 501.1 dynamic test).

- Europe: EN Standards (CE Marking).

- Australia/Middle East: Hybrid or AS standards.

⚠️ Critical Clause: “System must pass ASTM E283 (Air) and ASTM E331 (Water) before mass production.”

🔍 Step 2: How to Find and Screen Quality Chinese Manufacturers

This is the most critical phase: Supplier discovery + shortlisting.

1. How to Quickly Find Volume Suppliers

- 🌐Online Channels: Google is a start, but look for specific keywords like “turnkey curtain wall package from China” rather than just “glass window.”

- 🤝Offline Channels: Canton Fair, Big 5 (Dubai), IBS (Vegas).

2. First Round Screening: Is This Factory Worth Talking To?

Use this curtain wall supplier prequalification checklist:

- ✅ Establishment Time: >10 years preferred.

- ✅ Employees: >100 staff (implies capacity).

- ✅ Facility: Do they have their own testing rig?

- ✅ Capacity: Can they handle your square footage?

3. How to Distinguish a System Factory from a Trading Company

As a factory owner, I can tell you the tell-tale signs:

- Evidence: Ask for a video call. Ask to see the aluminum extrusion lines. A trader won’t have heavy machinery.

- Questions: Ask “How do you handle curtain wall value engineering without performance loss?” A trader will dodge; a factory engineer will propose profile optimization.

- Deep Dive: Ask about their curtain wall factory capability assessment process. Do they have in-house powder coating?

4. From Sample to Quote: Shortlisting to 2-3 Suppliers

📦 Requesting Samples

Don’t just ask for a “corner sample.” Ask for:

- Curtain wall aluminum extrusion thickness specification samples (cut sections).

- Thermal break polyamide strip specification curtain wall samples (is it PA66 GF25?).

- Curtain wall hardware brand equivalency specification physical samples.

💰 Comparing Quotes

Use a curtain wall supplier comparison matrix. Look for hidden costs. Does the price include packaging? Does it include the interface scope definition (GC vs facade contractor)?

🛑 Design Freeze: Establish a design freeze milestone. Any changes after this point trigger a facade change order process.

5. From Quote to Contract: Clauses That Must Be Dead Locked

- 🔒Brands: Specify Dow Corning 995 for structural silicone glazing sealant specification, not just “market standard sealant.”

- 🔒Testing: Include a curtain wall mockup testing plan.

- 🔒Responsibility: Define who owns the curtain wall shipping terms responsibilities (Incoterms).

🛡️ Step 3: Locking Down Material Specs and Certifications

Writing strict specifications is your primary defense against quality fade.

1. Writing Specs for Profiles, Glass, and Hardware

🏗️ Aluminum Profiles

- Alloy: Specify aluminum curtain wall profile alloy grade specification as 6063-T5 or T6.

- Finish: Define powder coating specification for curtain wall aluminum (e.g., AAMA 2605, AkzoNobel Interpon).

- Anodizing: Anodizing specification for curtain wall profiles must meet Class I (20-25 microns) for coastal projects.

🪟 Glass Selection

- Low-E: Define the low-e insulated glass unit specification for curtain wall. Single or double silver?

- Safety: Laminated glass specification for curtain wall (PVB or SGP interlayers).

- Fire: Fire-rated curtain wall glass specification where code requires.

🔩 Accessories

- Thermal Break: Ensure thermal break polyamide strip specification curtain wall is clearly defined to prevent condensation.

- Gaskets: EPDM gasket specification for curtain wall is non-negotiable for longevity.

2. Ensuring Compliance with Destination Codes

- 📋Testing: Does the project require ASTM E1105 field water test for curtain wall? Put it in the contract.

- 📋Reports: The curtain wall laboratory test report review checklist should verify that the tested sample matches your production drawings.

3. Mockups: When are they Mandatory?

For any project over 5,000 sqm or above 10 stories, a curtain wall mockup requirements in RFQ is essential.

The Mockup Validates:

- Constructability: Can it actually be assembled?

- Waterproofing: The ASTM E331 curtain wall water penetration test on a mockup saves millions in potential leaks later.

🕵️♀️ Step 4: Production QC and Pre-shipment Inspection

You cannot manage quality by hoping for the best. You need a formal curtain wall quality control plan for overseas manufacturing.

1. Critical QC Nodes in Production

- 🔍 Incoming Material: Check glass flatness and profile coating thickness.

- 🔧 Assembly: Check the “bites” of the sealant.

- ⚙️ Function: Test operability of vents.

2. Remote Quality Control

We provide clients with a curtain wall dimensional inspection record template filled out for every batch.

- 📸 Photos/Videos: Request daily footage of the structural silicone glazing sealant specification application process (the most critical bond).

- 📹 Live Video: Do a live walkthrough for curtain wall trial assembly inspection checklist.

3. Third-Party Inspection

For high-stakes projects, hire a third party inspection for curtain wall manufacturing (like SGS, Intertek, or a dedicated facade consultant). Define their scope using a curtain wall manufacturer audit checklist.

4. Pre-Shipment Checklist (Before Doors Close)

- 📦 Packaging: Verify anti-damage crating for curtain wall units. Are they A-frames?

- 🏷️ ID System: Use a curtain wall panel ID tracking system. Each panel must be labeled to match the curtain wall installation sequence labeling.

- 📄 Documents: Ensure the curtain wall packing list template matches the physical count perfectly.

🚢 Step 5: Commercials – Pricing, Payment, and Logistics

Understanding the financial and logistical structure is key to avoiding hidden costs.

1. Breakdown of a Curtain Wall Quote

- 🏗️ Materials: Aluminum, Glass, Accessories.

- ⚙️ Fabrication: Labor and machine time.

- 📐 Design: Shop drawings and engineering.

- 🚚 Logistics: Curtain wall ocean freight planning for project deliveries.

2. Incoterms: EXW vs FOB vs CIF

- EXW (Ex-Works): The customer picks up the goods directly from the factory. (High risk for you).

- FOB (Free on Board): The factory loads goods onto ships at the designated ports according to customer requirements.

- CIF (Cost, Insurance, Freight): The factory handles shipping to the port designated by the customer. This is the easiest option for first-time buyers. But it is also the most expensive.

💡 Advice: Check best incoterms for importing curtain wall systems based on your local logistics capability.

3. Logistics and Clearance

A full container load (FCL) is safer than LCL. Curtain wall panels are large and fragile.

Prepare the curtain wall customs clearance documents checklist (Invoice, Packing List, Bill of Lading, Certificate of Origin, Mill Certs).

4. Payment Terms for Risk Control

- 💰Deposit: Usually 30%.

- 💰Interim: Payment upon material arrival at factory (optional).

- 💰Balance: Safe T/T payment structure for curtain wall projects often links the balance payment to the Bill of Lading or a successful curtain wall pre-shipment inspection checklist.

- 💰L/C: Letter of credit for curtain wall procurement is good for very large projects but adds bank fees.

🤝 Step 6: Warranty and After-Sales

1. Defining the Warranty

- 📋 Scope: Differentiate between curtain wall warranty clauses for international suppliers (materials) vs. installation (usually the local contractor).

- ⏳ Duration:

- 10-20 years for PVDF coating and Glass.

- 5-10 years for gaskets.

2. Support from China

- 💻 Remote Tech Support: We use Zoom/Teams to guide site teams.

- 👷♂️ Onsite Support: For complex projects, we send engineers.

🏗️ Case Study: Nuvo Event Space

For the Nuvo Event Space project, we didn’t just ship the glass. We dispatched a team of technical supervisors to the site to oversee the installation of the oversized folding door systems and curtain wall interface.

“This onsite support agreement for curtain wall installation ensured the local team didn’t void the warranty through improper handling.”

3. Contractual Protection

Include a defect liability period for curtain wall contracts (usually 12 months post-installation) where a small retention money is held to ensure performance.

🌱 Sustainability and Long-Term Risk Control

1. Green Building Requirements

If your project is LEED or BREEAM certified:

- ♻️Materials: Ask for recycled aluminum documentation for curtain wall procurement.

- 🧪Chemicals: Ensure low VOC sealant requirements for curtain wall projects are met.

- 📄EPDs: Request EPD requirements for curtain wall components early.

2. Reducing Long-Term Risk

- 🚀 Pilot Projects: Start with a smaller building to test the curtain wall supplier due diligence questions.

- 📂 Records: Keep every email. Use a shared CDE (Common Data Environment) for curtain wall revision control best practices.

🚀 Summary: How to Systematically Launch Your Procurement

1. The Master Checklist (From “Finding” to “Landing”)

- 1️⃣ Define Scope: Use the curtain wall scope of work definition for procurement.

- 2️⃣ Shortlist: Run the curtain wall supplier comparison matrix.

- 3️⃣ Audit: Perform the curtain wall factory capability assessment.

- 4️⃣ Spec: Finalize aluminum curtain wall profile alloy grade specification and glass specs.

- 5️⃣ Test: Execute ASTM E283 curtain wall air leakage test on mockups.

- 6️⃣ Inspect: Follow the curtain wall factory inspection checklist.

- 7️⃣ Ship: Manage curtain wall customs clearance documents checklist.

💡 Best Time to Involve the Supplier?

Design Stage (DD). Engaging us during Design Development allows for curtain wall value engineering without performance loss. We can optimize cuts, reduce waste, and suggest standard dies that save $50/sqm.

✅ Immediate Next Steps (If You Have Drawings)

If you have your CAD files ready, here are the 7 things to do right now:

- ✔ Isolate the facade scope.

- ✔ Define your U-value and Wind Load targets.

- ✔ Determine if you need Unitized or Stick (or ask us).

- ✔ Set your budget target.

- ✔ Prepare your curtain wall technical submittal checklist.

- ✔ Draft your RFQ using our curtain wall RFQ checklist.

We are not just a factory; we are your facade partner. With our own extrusion lines, 10+ years of export experience, and a track record of onsite support (like at Nuvo Event Space), we bridge the gap between Chinese manufacturing capacity and Western construction standards.