🏙️ Stick-Built vs Unitized Curtain Walls: The 2025 Decision Guide

In the world of modern architecture, the façade is more than just a building’s skin; it is the primary defense against the elements and a defining statement of design.

📊 The High-Stakes Calculation

For today’s developers and general contractors, choosing the right system is a crucial decision that requires careful consideration of factors such as project timeline, budget, on-site logistics, and long-term risks.

The debate usually boils down to two heavyweights: stick-built vs unitized curtain wall systems. If you are currently standing at this crossroad, you are not alone.

⚠️ Risk Alert: Making the wrong choice can lead to scaffolding nightmares on high-rises or budget blowouts on low-rise boutique projects.

✅ What’s in This Guide?

In this comprehensive guide, we move beyond textbook definitions. Drawing from APRO’s decade of manufacturing experience, we will dissect the stick vs unitized curtain wall decision matrix across 12 critical dimensions—from tolerance management to cash flow—to help you make the most profitable decision for your 2025 project.

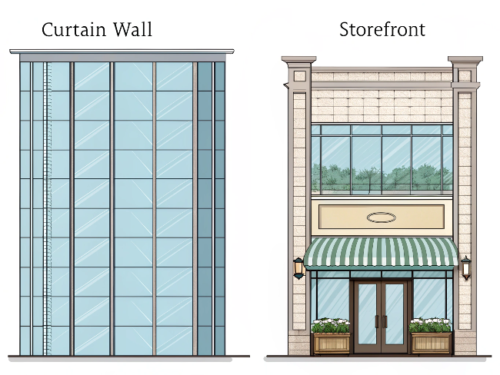

🎓 New to envelopes? You might want to start with our foundational article: What is a Curtain Wall? to understand the basics before diving into this comparison.

🏗️ What is a stick-built curtain wall system?

📝 Definition

A stick-built curtain wall system is a façade construction method where the frame components (mullions and transoms) are installed piece-by-piece on the building structure, followed by the installation of glass panels and sealing gaskets directly on-site. This system’s quality is highly dependent on on-site workmanship and weather conditions.

✅ The Pros (Why choose it?)

- ✔Lower Material & Shipping Costs: Components are shipped as loose bars (knocked down), maximizing container space and reducing shipping volume.

- ✔High On-Site Flexibility: It is easier to adjust framing on-site to accommodate irregular building structures or last-minute stick-built curtain wall tolerance adjustments.

- ✔Low Initial Manufacturing Lead Time: Less time is needed for factory assembly, allowing materials to arrive at the site sooner.

❌ The Cons (The risks)

- ✖Slower Installation: Requires multiple sequential steps on-site (framing → glazing → sealing), making the overall stick-built curtain wall installation sequence longer.

- ✖Quality Variability: Sealing quality is vulnerable to site dust, rain, and worker skill levels.

👍 Best Uses for Stick-Built Systems

- Low to Mid-Rise Buildings: Typically under 15-20 meters where scaffolding or boom lifts are easily accessible.

- Complex, Irregular Façades: Projects with many angles, multifaceted planes, or non-repetitive geometries where factory standardization is difficult.

- Projects with Loose Site Schedules: Where speed of enclosure is not the critical path.

🚩 Not Recommended For (Red Flags)

- High-Rise Towers: The cost and danger of external scaffolding or swing stages at great heights make it impractical.

- Regions with Expensive Labor: The high man-hours required on-site can destroy the budget in countries like the USA or Australia.

- Rainy Climates: Installation often halts during rain, causing unpredictable delays.

💡 Pro Tip: The Hybrid Solution

Before you decide, consider the semi-unitized curtain wall system (often called the ladder system). It combines aspects of both—pre-assembling the metal frame in the factory (like a ladder) while installing the glass on-site. This is often a great middle-ground for projects that need speed but have handling limitations. Determining when to use semi-unitized curtain wall options usually depends on whether you have crane access but limited glazing manpower.

🏢 What is a Unitized Curtain Wall system?

📝 Definition

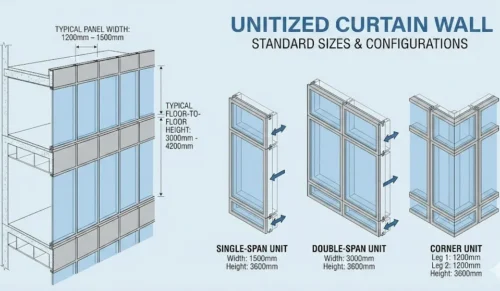

A unitized curtain wall system is a façade method where the curtain wall components (frame, glass, and seals) are fully assembled and glazed into standard panel units within a controlled factory environment. These units are then shipped to the site and hoisted onto anchors, emphasizing consistency in quality and speed of installation.

✅ The Pros (Why choose it?)

- ✔Rapid Enclosure: Simultaneous fabrication and site preparation allow for a significantly faster unitized curtain wall installation sequence.

- ✔Superior Quality Control: Structural glazing and sealing are performed in a dust-free factory environment.

- ✔Weather Independence: Factory production continues regardless of rain or snow on the job site.

❌ The Cons (The risks)

- ✖Higher Transport & Logistics Costs: Shipping bulky, fully assembled panels means shipping “air,” increasing freight costs per square meter.

- ✖Design Inflexibility: Once the dies are cut and panels are made, late design changes are incredibly expensive and disruptive.

👍 Best Uses for Unitized Systems

- High-Rise & Skyscrapers: The standard solution for towers (20+ floors) due to crane installation methods.

- Highly Repetitive Façades: Modular designs maximize factory efficiency and mold utilization.

- Tight Deadlines: Projects where closing the building envelope quickly to allow interior trades to start is crucial.

🚩 Not Recommended For (Red Flags)

- Small Projects (< 3,000 sqm): The high cost of custom molds and system design engineering often outweighs the installation savings.

- Renovations with Poor Structure: If the existing building has extreme deviations, unitized panels may not fit without expensive custom anchors.

🔗 Learn More: For a broader look at how these fit into the market, check our guide on 5 Types of Curtain Wall Systems, which covers point-fixed and louver options as well.

⚖️ Stick-Built vs. Unitized Curtain Wall: The Comparison Matrix

To make an informed decision, you need to look beyond the basic definition. Here is a 12-point stick vs unitized curtain wall decision matrix comparing every aspect of execution:

| Feature | Stick-Built System | Unitized System |

|---|---|---|

| Construction Method | Site-assembled (Mullion + Transom + Glass) | Factory-assembled (Complete Panels) |

| Best For | Low-mid rise, Complex shapes, High changes | High-rise, Repetitive modules, Tight schedule |

| Speed on Site | Slow (Sequential steps) | Fast (Parallel processing & Hoisting) |

| Design Flexibility | High (Field adjustable) | Low (Early freeze required) |

| Quality Consistency | Variable (Depends on site labor) | High (Factory controlled) |

| Site Constraints | Low impact (Small storage needed) | High impact (Crane & large staging needed) |

| Labor Dependency | High dependency on site skilled labor | Shifted to factory; less site labor needed |

| Tolerance Sensitivity | Forgiving (Field cuts possible) | Sensitive (Requires precise anchoring) |

| Water Leakage Risk | High risk at site-applied seals | Risk managed via drainage path design |

| Maintenance | Easy localized repair | Requires “Replaceability” design upfront |

| Schedule Risk | Weather & Labor shortages | Factory capacity & Shipping logistics |

| Cost Structure | Lower BOM, Higher Labor/Risk | Higher BOM/Logistics, Lower Labor/Risk |

🔍 Deep Dive: Analyzing the Critical Differences

Let’s break down the table above. Why do industry experts say that “cheap” stick systems often end up being more expensive?

1. Stick vs Unitized: How does the construction method differ?

Stick systems build the frame and complete glazing and sealing mostly on-site, acting like a customized carpentry job. Unitized systems complete most fabrication in the factory and rely on on-site hoisting and assembly, acting like a modular LEGO assembly.

🎲 Risk Shift: With stick systems, you are betting on the weather and the mood of the worker. With unitized, you are betting on the supply chain.

- Factory Scope: Framing, glazing, curing structural silicone, QA/QC.

- Site Scope: Hoisting bundles, setting mullions, lifting glass, applying wet sealant.

2. Which is better for High-Rise / Large Scale?

Stick-built works better for low-to-mid-rise or highly customized façades. Unitized is typically better for high-rise and large repetitive façades where speed dominates.

Why? Once you go above 20 floors, external scaffolding becomes a massive liability. Unitized hoisting installation allows crews to work from the floor slab inside the building with a mini-crane—safer, faster, and no external footprint.

3. Which installs faster? Why?

Stick-built is slower due to sequential field tasks. Unitized is faster because fabrication is parallelized in the factory.

While your site team is pouring the foundation, the factory is already manufacturing panels. Industry data suggests a unitized team can install 30% to 50% more square meters per day.

4. Which is more suitable for frequent changes?

Stick-built is more adaptable to late-stage adjustments. Unitized is less tolerant; modifications often require refabrication.

In a stick system, a skilled worker can cut a mullion on-site if it’s 10mm off. In unitized, you might have to scrap the whole panel. This highlights the importance of the “Design Freeze.”

5. Which has more stable quality?

Stick-built quality varies with crew skill. Unitized quality is consistent due to factory control.

“When we apply structural silicone in the factory, we control humidity and temperature. On a windy, dusty job site, even the best worker can’t guarantee that level of adhesion.” — APRO Factory Manager

6. Which is safer for poor site conditions?

Stick-built demands stable access. Unitized is ideal for congested sites but requires intense logistics planning.

- Staging Area: Space for bulky stillages.

- Crane Time: Dedicated hook time.

- Protection: Panels damage easily if hit.

7. Which relies more on skilled labor?

Stick-built depends heavily on field installers.

Unitized shifts labor to the factory.

Importing a unitized system where labor cost is absorbed in the factory is a massive financial win in regions with high labor costs.

Thinking of sourcing from overseas? Read our guide on How to Import.

8. Which is more sensitive to survey errors?

Stick-built is forgiving.

Unitized is sensitive; inaccurate surveys can cause fit-up issues.

Tolerance Management: We design 3-way adjustable brackets (In/Out, Up/Down, Left/Right) to absorb up to ±25mm of deviation. Beyond that, significant rework is required.

9. Which is more prone to leakage?

Stick-built risk is in field-applied sealants.

Unitized uses a “Pressure Equalized Rain Screen” principle to manage water at joints.

Key Check: Ensure the “End Dam” is perfectly sealed in the factory. Stick-built failures are usually due to wet sealants applied in damp conditions.

10. Which is easier to maintain?

Stick-built is easier for localized repair.

Unitized requires a “Stack Joint” design for efficient panel replacement.

Replacing a panel on the 40th floor requires specific logistics that must be documented in the O&M manual.

11. Which has greater schedule risk?

Stick-built risks: Weather, site congestion, labor variability.

Unitized risks: Factory capacity, shipping, hoisting windows, design freeze.

12. Which is cheaper? The illusion of “Cheap”

Stick-built has lower material costs but higher labor/risk.

Unitized has higher BOM but faster installation.

Don’t look at material cost alone. Calculate the “Total Installed Cost.” Shaving 3 months off construction saves bank interest and gains rental income that often outweighs the material difference.

📋 Performance Specs & Testing Checklist

Regardless of whether you choose stick or unitized, the system must perform. Do not rely on verbal promises. Ensure your tender documents reference these standards.

According to a whitepaper by the Glass Association of North America (GANA), field testing is the only way to verify installation quality.

| Test | Where | What it checks | Best used for |

|---|---|---|---|

| ASTM E283 | Lab | Air leakage (airtightness risk) | comfort/energy-focused projects |

| ASTM E331 | Lab | Static water penetration resistance | rain/wind-driven rain risk |

| ASTM E1105 | Field | Installed system water test | site QA and acceptance checks |

| AAMA 501.1 | Verification | Dynamic water resistance | higher-risk wind/rain exposure |

- 🧪 ASTM E283 curtain wall air leakage test: Critical for energy modeling.

- 💧 ASTM E331 curtain wall water penetration test (lab): Used during the PMU phase.

- 🏗️ ASTM E1105 curtain wall field water penetration test: The gold standard for site testing.When to specify? Typically, we recommend testing the first 5% of installed bays to catch systemic errors early.

🏗️ Project Case Note: Minerals Commission Office Ghana Project

For our Minerals Commission Office Ghana Project, we utilized a custom stick-built system because of the highly irregular steel substructure. However, we mandated ASTM E1105 testing on specific zones. This rigorous QC caught a minor gasket compression issue early, saving the client thousands in potential future repairs.

🤔 How to Choose the Right Curtain Wall System?

Still undecided? Use this 6-step decision framework to clarify your strategy.

✅ The Decision Checklist

- 1

Define Project Needs:

What is the height, geometry, and degree of façade repetition? - 2

Assess Schedule & Budget:

Is time money? Or is cash flow the restriction? - 3

Evaluate Labor:

Is local skilled labor available, or should you import labor-saving unitized panels? - 4

Review Design Flexibility:

Are drawings frozen, or are changes likely? - 5

Confirm Performance Targets:

What are the wind load (kpa) and thermal (U-value) targets? - 6

Verify Execution Capability:

Does your subcontractor have crane access for unitized or scaffolding for stick?

📝 Team Checklist: The Go/No-Go Decision

Before you sign a contract, gather your project manager, architect, and structural engineer to answer these critical questions:

- ☐

Geometry:

Is the façade vertical and flat (Unitized friendly) or multi-plane and twisted (Stick friendly)? - ☐

Repetition:

Do we have enough identical panels (standard floors) to justify the mold cost for unitized? - ☐

Site Logistics:

Do we have a staging area for 40-foot containers and crane hook time? - ☐

Timeline:

Can we freeze the design now to start factory production? - ☐

Structure:

Is the concrete tolerance within ±25mm? If not, can stick-built absorb the error better? - ☐

Labor:

Are we easily able to find skilled subcontractors for installation?

📨 RFQ Package Checklist

Ready to get a quote from a manufacturer like APRO? To get an accurate comparison of stick vs unitized curtain wall costs, your RFQ (Request for Quotation) package must include the following.

📋 The Essential RFQ List

- ➤Drawings:

Architectural elevations, module layout, key details/sections, interfaces. - ➤Dimensions:

Floor-to-floor height, slab edge conditions, tolerance notes, survey data. - ➤Performance Targets:

Wind load report, U-value requirements, and STC (acoustic) ratings. - ➤Materials:

Specs for aluminum finish (PVDF/Powder coat) and Glass makeup (Low-E/Laminated). - ➤Scope Boundaries:

Supply only? Or Supply & Install? Who handles hoisting? - ➤Mockup & QA:

Requirements for visual samples, curtain wall mockup testing requirements, and inspection checkpoints.

Need to find a reliable supplier?

Check our list of Top 10 Curtain Wall Manufacturers in China.

🚫 Common Mistakes & How to Avoid Them

🛠️ Stick-built Pitfalls

- Inconsistent Field Sealing: Assuming every worker seals perfectly.

✅ Fix: Implement a rigorous curtain wall site inspection checklist with photo logs for every 10 meters of seal.

- Blocked Drainage: Weep holes getting clogged by debris during construction.

✅ Fix: Verify drainage paths before snapping on the covers.

- Tolerance Handling: Stick-built curtain wall tolerance adjustment not planned, causing misalignment and rework.

✅ Fix: Build a tolerance management plan before installation—start with verified as-built survey control lines, then use adjustable anchors/shims and hold-point inspections to catch drift early.

🏭 Unitized Pitfalls

- Embed Misalignment: Concrete anchors cast in the wrong spot.

✅ Fix: Conduct a 3D scan of the structure before shipping panels to verify fit.

- Logistics Bottlenecks: Trucks arriving without a crane ready to lift.

✅ Fix: Detailed unitized curtain wall logistics planning meetings with the GC.

- Lack of Replaceability: Unitized curtain wall replaceability design not considered, making future maintenance expensive.

✅ Fix: Design unitized panels with a defined replacement strategy—accessible fasteners/cover caps, clear removal path, lifting points, and a documented swap procedure approved during mockup.

🏗️ Factory Experience

We once had a client in downtown Melbourne who chose a prefabricated modular structure to speed up construction, but they overlooked the reason why Melbourne is known as the “windy city.” As a result, after the prefabricated panels arrived on site, the tower crane was unable to operate for three days a week due to strong winds. Ultimately, we had to temporarily redesign the layout of the construction area.

Since then, when developing product plans for curtain wall projects, we always consider the local climate conditions, including but not limited to wind speed, snow season, seawater corrosion, and desert climate.“

🌍 Universal Mistakes

- ⚠Unclear Scope Interfaces: Who waterproofs the gap between the curtain wall and the concrete wall? This is the #1 cause of disputes.

- ⚠Late Design Freeze: Changing the glass color after production starts. This is a budget killer.

🏁 Conclusion: Making the Right Choice

There is no “better” system, only the system that is better for your specific constraints.

✅ Choose Stick-Built

If you are building a complex, low-rise boutique hotel and need flexibility.

✅ Choose Unitized

If you are building a 40-story office tower and need speed, safety, and consistent quality.

Still unsure which path to take?

Don’t gamble with your building envelope. Send your elevation drawings to the APRO engineering team. We will provide a comparative analysis of stick vs unitized curtain wall costs specific to your project, ensuring you build on time and on budget.