Introduction

Curtain Wall Glass Selection Guide

Curtain wall projects live or die on glass selection. Not because glass is “the expensive part” (though it often is), but because the wrong glass make-up can quietly create a chain reaction: unexpected distortion complaints, overheating behind spandrels, seal failures in IGUs, edge damage during installation, condensation at the perimeter, or safety concerns after breakage.

In real projects, “choose glass” is never just “pick tempered” or “pick Low-E.” What you’re really doing is matching system type + support condition + performance targets + façade zone to a glass build-up that can be fabricated, transported, installed, and maintained—while still meeting code, test requirements, and owner expectations.

📋 This article is written like a specifier’s walkthrough:

First, we’ll map the most common glass types used in curtain wall projects.

Then we’ll match glass to curtain wall system types (framed, unitized, glass fin, point-supported, double-skin, sloped glazing).

Next, we’ll select glass by performance requirements (structural, thermal, acoustic, safety, durability, visual quality).

After that, we’ll refine by façade zone (vision, spandrel, corners, entrances, slab edges).

Finally, we’ll give a step-by-step workflow and copy-paste spec language you can actually use in RFQs and submittals.

Along the way, we’ll reference the kinds of tests and rating systems that appear repeatedly in real specifications—like ASTM E283 for air leakage and ASTM E331 for water penetration under uniform static air pressure. We’ll also use the NFRC rating framework as a practical “industry data standard” for U-factor / SHGC style performance language.

⚠️ Industry Lesson: We’ll end with the famous case of the John Hancock Tower (Boston), where curtain wall glazing failures led to a major reglazing effort—an evergreen reminder that glass selection is engineering, not cosmetics.

Common Glass Types in Curtain Wall Projects

The Building Blocks of Performance

Below are the glass “building blocks” you’ll see again and again. You rarely use them alone—you combine them into a make-up that matches the system and performance targets.

1. Float Glass (Annealed Base Glass)

Float glass is the baseline product most architectural glass starts from: flat, clear (or tinted), and produced by floating molten glass on molten tin. On its own, standard annealed float glass is not a default choice for most curtain wall vision zones because it breaks into large shards and has lower strength compared to tempered or heat-strengthened.

- Laminated assemblies where the glass plies may be annealed for optical reasons (depending on design and safety requirements).

- Spandrel and shadow box areas where impact risk is low and the assembly is protected.

- Certain interior lite positions within an IGU in low-risk zones (only when permitted by code/spec and validated by safety requirements).

- Float glass is often the best “optical” baseline (less roller-wave than tempered), but the safety and strength limitations mean you typically upgrade it through heat strengthening, tempering, laminating, or insulating.

- If you are trying to solve “waviness” complaints in a premium façade, you don’t start by banning tempered glass—you start by controlling thickness, heat treatment type, and visual quality criteria, plus mock-up review.

(Internal link: Curtain Wall Parts: The Complete Guide… for how glass relates to mullions, gaskets, setting blocks, and bite.)

2. Tempered Glass (Safety + Strength)

Tempered glass is heat-treated to increase strength and to change breakage behavior. When it fails, it breaks into small fragments rather than large, dangerous shards—one reason it’s widely used as “safety glazing” in many curtain wall applications.

- Vision lites in many commercial curtain walls (especially where human impact is a concern).

- Outer lites exposed to higher thermal stress (sun, wind, temperature swings), when the risk of thermal breakage is higher.

- Spandrel outer lites when heat build-up is expected (but spandrel requires additional strategy—more on that later).

- Tempered glass can show anisotropy (a visible pattern under polarized light) and sometimes greater distortion than annealed, especially at larger sizes.

- Tempered glass has a known (low-probability) risk of spontaneous breakage due to nickel sulfide inclusions. That’s why many specs include discussion of heat soak testing for tempered glass in sensitive projects.

- When we write specs, we treat tempered glass as a tool, not a religion: use it where safety/strength is needed, and control the side effects with mock-ups, visual criteria, and careful make-up selection.

3. Laminated Glass (PVB/SGP Interlayer and Why It Matters)

Laminated glass is two (or more) plies bonded with an interlayer. The interlayer holds fragments after breakage, improves safety, and can deliver acoustic and security benefits. In curtain walls, laminated glass is often the difference between “breakage” and “hazard.”

- PVB (polyvinyl butyral): widely used, good optical clarity and acoustic options, common and cost-effective.

- SGP (ionoplast / structural interlayer): much higher stiffness, better for structural performance (especially in point-supported glass, fins, or when post-breakage capacity is critical).

- Overhead glazing (skylights / sloped glazing): laminated is typically expected because you need post-breakage retention.

- Fall protection zones or guard applications where glass must remain in place after breakage.

- Acoustic upgrades: laminated glass with acoustic interlayers can reduce sound transmission.

- Point-supported / spider systems: laminated with SGP is often favored because holes and concentrated loads demand higher interlayer performance.

🏭 Factory Experience #1: Edge Quality Lesson

In one project, the client specified laminated IGUs for a high-visibility façade but wanted aggressive lead time and minimal cost. Early samples looked fine—until we started seeing edge issues during processing: small chips at the laminate edge translated into micro-cracks that later grew during handling and installation. We paused production, pulled the batch, and did a root-cause review across our line:

- We tightened edge seaming quality (not just “polish,” but consistent arris and removal of sharp micro-notches).

- We changed our handling method so the glass never rode on a hard edge; we used soft edge supports and adjusted rack spacing.

- We coordinated with the façade contractor to revise site handling: suction cup placement and rotation paths were damaging edges during turn-over.

The result: we eliminated repeat edge damage and improved field yield. The key lesson was not “laminated glass is fragile”—it’s that laminated glass makes edge quality and handling discipline non-negotiable. That kind of production reality is why you should always treat “laminated” as a full system decision: glass edge, interlayer, IGU design, and installation method all interact.

4. Insulated Glass Units (IGU): Double and Triple Glazing

An IGU combines two or three panes separated by a sealed airspace (often argon-filled) to improve thermal performance and reduce condensation. IGUs are common in curtain wall vision areas because they help meet U-factor and SHGC targets.

- Double glazing is the most common curtain wall choice because it balances performance, weight, and cost.

- Triple glazing can improve U-factor further but adds weight, thickness, edge complexity, and cost. It’s typically justified in extreme climates or when energy targets are aggressive.

- Spacer system (thermal bridge at the edge)

- Gas fill retention

- Sealant system durability

- Coating selection and surface position

- Moisture control and desiccant capacity

🏭 Factory Experience #2: IGU Seal Failure Prevention

A client once came back with a painful complaint: after installation, several IGUs showed early fogging—classic symptom of moisture entering the cavity. Instead of arguing, we treated it like a failure analysis project:

- We requested returned units and cut them open to inspect primary and secondary seal integrity.

- We checked our production records—sealant mix ratios, cure time, humidity conditions, and spacer batch.

- We discovered the real issue wasn’t “bad glass.” It was a combination of (a) inadequate cure time before packing due to schedule pressure and (b) edge contamination from a cleaning solvent that wasn’t fully flashed off.

- We changed our internal process: mandatory cure window, solvent control, and a moisture checkpoint before packing.

- We renegotiated delivery sequencing with the client: we shipped in batches aligned to installation, reducing time pressure and handling.

The fix wasn’t glamorous, but it prevented repeat failures and rebuilt trust—because we solved the mechanism, not the symptom. This is why, in specs and submittals, we insist on IGU warranty terms + manufacturing quality documentation, not just a nice cut sheet.

5. Low-E Glass (Surface Location Matters)

Low-E coatings reduce heat transfer and manage solar gain. They’re not “one thing.” In performance specs, you’ll see:

- Single silver: often balanced performance, moderate cost.

- Double/triple silver: stronger solar control and/or improved thermal performance, often used in demanding commercial façades.

A Low-E coating placed on the wrong surface can change solar control, visible reflectance, and even durability. That’s why your spec should not just say “Low-E”; it should say the glass make-up line and coating location (we’ll show how later).

If your project uses NFRC-style language (U-factor, SHGC), remember NFRC’s rating approach treats the whole product/system performance and is used broadly to describe those metrics in a consistent way.

6. Reflective / Solar Control Coatings

Solar control is where aesthetics and physics fight. Your toolkit includes:

- Tinted glass: reduces glare and solar gain but can reduce daylight and shift color.

- Reflective coatings: strong solar control and a specific “mirror” look; can create glare issues and neighborhood complaints.

- Spectrally selective coatings: deliver good solar control while preserving visible light, often a “premium default” for modern office towers.

In London, the building at 20 Fenchurch Street became famous for concentrated reflected sunlight at street level—an extreme but memorable reminder that façade reflection and solar geometry can cause real-world problems. That doesn’t mean reflective glass is “bad.” It means you must model and review reflection and glare risk during design, especially on concave forms or highly reflective surfaces.

7. Heat-Strengthened Glass (Strength with Better Optics)

Heat-strengthened (HS) glass sits between annealed and fully tempered in strength. It breaks into larger pieces than tempered (so it may not meet all “safety glazing” requirements by itself), but it often has better optical quality and lower distortion risk than fully tempered.

Where HS is commonly specified:

- Outer lite in an IGU when thermal stress is high and optical performance matters.

- Projects where temper distortion is a known concern (large lites, high reflectivity, tight aesthetics).

- HS is often paired with laminating when you need safety + post-breakage behavior: e.g., HS + SGP + HS in demanding structural glass applications.

8. Special Performance Glass (Fire, Blast, Impact)

These are not “single product choices.” They’re complete systems:

- Fire-resistant glazing involves tested assemblies, framing, and certified build-ups.

- Blast-resistant glazing depends on glass make-up, laminate interlayer performance, anchorage, and test criteria.

- Hurricane impact requires compliance with specific code/test requirements and is not just “tempered glass.”

- Safety glazing is a code-driven concept: it’s about breakage mode, impact zones, and hazard mitigation.

In these scenarios, you do not “guess.” You reference tested assemblies, approved suppliers, and verified test reports—and you align the glass make-up with the curtain wall system and anchorage details.

Selecting Glass Based on Curtain Wall System Type

Practical Mapping for System-Specific Performance

Here’s the practical mapping: the same glass performs differently depending on how it’s supported and how the façade is assembled.

1. Framed Curtain Walls (Most Common Commercial System)

Framed curtain wall systems (captured variants) support glass with pressure plates, gaskets, and caps. Your glass choices focus on strength, thermal goals, and visual quality.

A. Visible (Capped) Curtain Wall

- Typical choices: Double IGU with Low-E (outer lite HS or tempered; inner lite tempered or laminated depending on safety). If acoustics matter, consider laminated inner lite.

- Key risk points: Sightline consistency and visual distortion across repetitive bays. Perimeter sealing and gasket quality—small mistakes scale across thousands of panels.

B. Semi-Visible Curtain Wall

Semi-visible systems reduce external caps in one direction. Glass build-up often remains similar to visible systems, but you must watch:

- Edge bite and support consistency.

- Alignment tolerances that can create visual “waving” lines.

C. Hidden-Frame (Captured Look / Minimal Caps)

Hidden-frame looks push more attention onto:

- Edge detailing and alignment.

- Coating uniformity (color/reflectance) because the façade reads as a continuous plane.

Practical default: High-quality IGUs with controlled optics and a well-defined visual standard in mock-up approval.

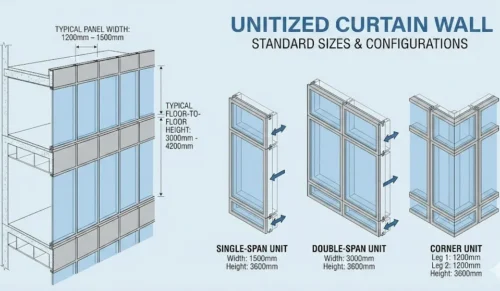

2. Unitized Curtain Walls (Factory Prefabricated Modules)

Unitized systems move much of the assembly into the factory. Glass selection priorities shift slightly:

- Weight and handling limits become central (module shipping and hoisting).

- Repeatability becomes a performance advantage: consistent seal compression, consistent gasket installation.

- Double IGU with Low-E; frequent use of laminated inner lite when safety/acoustics matter.

- In tall towers, glass thickness may increase at corners/high-pressure zones.

The question you should ask early: “What is the maximum unit weight per module and per lite?”

That single constraint can reshape glass thickness and whether triple glazing is feasible.

(Internal link: Stick vs Unitized Curtain Wall: How to Choose?)

3. Glass Wall Series (Structural Roles)

These systems push glass toward structural roles. This is where laminated glass—often with SGP—shows its value.

A. Glass Fin Curtain Wall

Glass fins act like structural members. Recommended direction:

- Laminated glass with SGP for fins (stiffness, post-breakage behavior).

- For vision lites supported by fins, make-ups often trend more conservative because deflection control matters.

Underestimating edge support and point loads at fin connections. Ignoring long-term creep behavior of interlayers in hot climates.

B. Point-Supported (Spider) Curtain Wall

Spider systems introduce drilled holes and stress concentrations. Common practice:

- Laminated glass (often SGP) to provide redundancy and post-breakage capacity.

- Careful hole edge finishing and strict fabrication quality control.

A simple rule: if the system includes holes, you stop thinking “glass panel” and start thinking “engineered component.”

4. Double Skin Facades (Outer/Inner Layer)

Double-skin façades have two layers with a ventilated cavity. Glass selection becomes “role-based”:

- Outer skin: solar control, durability, reflection management, weathering.

- Inner skin: airtightness, thermal insulation, acoustics, occupant comfort.

- Outer: solar control coating or frit strategy to manage heat.

- Inner: high-performance Low-E IGU designed for energy and condensation control.

The most common failure is not glass—it’s operational complexity: shading devices, cleaning access, and maintaining the cavity function.

5. Sloped Glazing / Skylight Systems

Overhead glazing changes the safety baseline. Drainage + Thermal + Safety Upgrades are required.

- Laminated glass is commonly expected for post-breakage retention.

- Drainage details become more sensitive because water sits and moves differently on slopes.

- Heat build-up can be higher; thermal stress and seal durability must be considered.

Laminated IGU (often laminated inner lite at minimum; sometimes laminated both sides depending on risk and code). Clear specification of slope conditions, drainage, and cleaning access.

6. Related Contexts (Window Wall & Storefront)

Window Wall Systems

Window wall systems are not curtain wall, but they show up in early comparisons. The key difference is support condition: window walls sit between slabs. Glass make-ups may look similar (IGUs with Low-E), but slab-edge detailing and perimeter air/water transitions often dominate performance outcomes.

(Internal link: Curtain Wall vs Window Wall: How to Choose Guide? 2026)

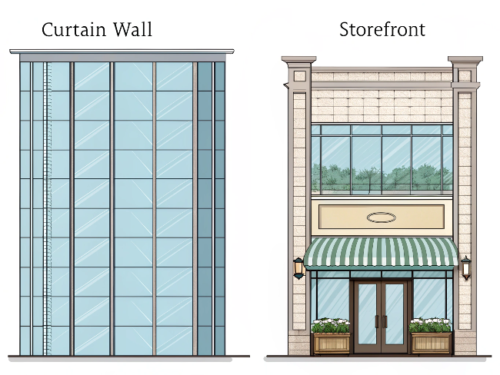

Storefront Systems

Storefronts are typically lower-rise opening systems used at podiums, retail, and entrances. Glass selection can overlap with curtain wall at the material level (tempered, laminated, IGU), but performance and anchorage expectations differ.

Tip: If your project scope includes storefront at podium levels and curtain wall above, align glass appearance and coating to avoid a visible mismatch across the façade.

Selecting the Right Glass Based on Performance Requirements

The “Why” Behind the Choice

This section is where specs become “real.” You’re not choosing glass types; you’re choosing tradeoffs.

1. Structural: Wind Load, Thickness, Deflection, Edge Support

- Design pressure (positive and negative).

- Glass thickness and ply arrangement.

- Support conditions (2-side vs 4-side support; captured vs structural glazing; point supports).

- Deflection limits (comfort and visual criteria as well as engineering).

- Four-side support captured systems typically allow more flexible make-ups than point-supported systems.

- Corners and high-pressure zones often require thicker glass; don’t assume “one thickness fits all.”

- Identify the highest design pressure zones (corners, parapets, top floors).

- Size glass for those zones (or plan zone-based thickness).

- Confirm the system can physically accept the glass thickness (bite, gasket range, pocket depth).

- Validate with engineering calculations and submittals.

2. Thermal Performance: U-Value, SHGC, Condensation

Thermal performance is not just glass; it’s the whole assembly. But glass is a major lever.

- U-factor: heat transfer rate (lower is better).

- SHGC: how much solar heat enters (lower reduces cooling load, but climate and daylight goals matter).

- Condensation risk: interior surface temperature and humidity interaction.

- Thermal bridging: frame and edge effects can erase glass gains.

NFRC methods are widely referenced for describing U-factor and related fenestration metrics in a consistent framework. Even if you’re not in a strictly NFRC-labeled market, using that vocabulary helps your specs become measurable.

- Start with climate and building type.

- Decide if you’re cooling-dominated (solar control priority) or heating-dominated (U-factor priority).

- Choose coating and glazing make-up accordingly.

- Then coordinate with frame thermal breaks—because “great glass in a weak frame” is still a weak envelope.

3. Acoustics: STC/OITC Strategies

For hotels, airports, highways, or dense urban projects:

- STC focuses on speech frequencies.

- OITC better represents lower-frequency outdoor noise (traffic, aircraft).

- Increase mass (thicker plies).

- Use laminated glass with acoustic interlayer.

- Use asymmetric make-up (different thicknesses) to reduce resonance.

If the curtain wall or window wall leaks air, your acoustic ratings suffer. That’s why air leakage testing language matters. ASTM E283 defines the method used to measure air leakage through exterior windows and curtain walls under specified pressure differences.

In plain terms: acoustics is glass + seals + perimeter continuity. Treat it as one system.

4. Safety and Post-Breakage Performance

Safety is a combination of break pattern (tempered vs annealed), post-breakage retention (laminated), and hazard mitigation (does glass stay in place?).

- Vision areas near occupants: tempered or laminated depending on impact zone and code requirements.

- Overhead/sloped glazing: laminated is widely expected because fragments must not fall.

Practical: Always define post-breakage expectations in your spec, especially for areas over public sidewalks, entrances, and atriums.

5. Durability: Seal Failure, Edge Chipping, Risk Management

Durability is where projects bleed money over time.

- IGU seal failure → fogging.

- Edge damage → cracks during install.

- Thermal stress → breakage in spandrels or high-absorption conditions.

- Nickel sulfide inclusion risk in tempered glass (low probability, high impact).

- Specify IGU quality documentation and warranty.

- Control edge quality, handling, and installation method.

- Use mock-ups and test planning early.

Water performance is not an opinion. ASTM E331 is used to evaluate resistance to water penetration under uniform static air pressure differences. If your project is high-wind, your water test pressures and detailing must match reality, not just a typical catalog value.

6. Visual Quality: Haze, Distortion, Anisotropy

The “premium façade” fight is often visual.

- Haze and clarity differences across batches.

- Distortion (roller wave, bow).

- Anisotropy patterns in tempered glass.

- Color shift from coatings, especially at angles.

- Reflection consistency across elevations.

- Require a visual mock-up and define the acceptance criteria.

- Control coating selection and production batches.

- Coordinate spandrel appearance early (because spandrel mismatches are a common owner complaint).

Facade Zone Glass Selection

Where the Glass Sits Changes the Rules

Even with the same system, glass selection changes by zone.

1. Vision Zones (Daylight, Color, Reflection)

Vision glass is what people see and judge.

- Color consistency across elevations.

- Balanced SHGC and visible transmittance.

- Controlled reflection.

- Double IGU with spectrally selective Low-E for many office towers.

- Laminated inner lite if acoustics or safety calls for it.

2. Spandrel Zones (Heat Build-Up, Mismatch Risks)

Spandrel is where good façades get embarrassed.

- Insulation behind glass increases temperature.

- Paint/coating appearance shifts with heat and lighting.

- “Ghosting” or uneven appearance can appear over time.

- True spandrel glass solutions with tested compatibility.

- Shadow box assemblies to reduce harsh appearance transitions.

- Opaque panel alternatives when consistent appearance is critical.

Tip: Treat spandrel as its own spec item, not an afterthought.

3. Corners and High-Pressure Zones

Corners see higher wind pressures. Practical steps:

- Identify corner zone pressures early.

- Specify thicker glass or laminated make-ups in those zones.

- Confirm system bite and gasket range.

- Validate with calculations.

This is also where you often see upgraded heat treatment choices to manage stress and distortion.

4. Entrances / Human Contact Zones

Entrances bring:

- Higher impact risk.

- More public exposure.

- Greater security concern (depending on project).

- Safety glazing requirements drive tempered/laminated decisions.

- Laminated glass can improve post-breakage retention and delay forced entry in some scenarios (system dependent).

5. Slab Edge / Shadow Box Interfaces

At slab edges, you manage:

- Alignment tolerances.

- Transition details.

- Appearance (shadow boxes, back pans, insulation).

Glass selection alone doesn’t solve this—coordination does. But you may adjust spandrel glass type, coating, or opacity to maintain a consistent exterior appearance.

Step-by-Step Workflow

How to Choose Curtain Wall Glass Like a Designer/Specifier

This is the “walk through it like you’re on the project” part.

Step 1 — Confirm System Type + Support Condition

- Captured framed?

- Structural silicone glazing (SSG)?

- Unitized modules?

- Glass fin / spider?

- 2-side, 4-side, point supports, holes, fin connections.

Why it matters: the same IGU that works in a captured system can be unsafe or impractical in a point-supported system.

(Internal link: Five Types of Curtain Wall Systems: Key Differences)

Step 2 — Lock Performance Targets

Don’t pick glass before targets. Set:

- Design pressure (including corner zones).

- Air leakage target and test method language (ASTM E283 defines the method).

- Water penetration target and method (ASTM E331 defines the method).

- Thermal targets (U-factor / SHGC) aligned to your energy goals; NFRC language helps standardize these metrics.

- Acoustic targets (STC/OITC where relevant).

Require the contractor to submit performance documentation (test reports, calculations) early. Performance is easiest to fix on paper, hardest to fix at 40 floors.

Step 3 — Choose Glass Make-Up

- Monolithic: limited use in modern curtain walls (rare in premium vision zones).

- Laminated: safety and post-breakage retention; acoustics and security.

- IGU: thermal baseline for most curtain walls.

- Laminated IGU: common premium solution combining thermal + safety.

- Overhead? → laminated is likely required.

- High acoustics? → laminated inner lite.

- High thermal targets? → IGU, maybe triple.

- Point-supported? → laminated (often SGP).

Step 4 — Decide Interlayer and Coating Orientation

This step prevents expensive mistakes.

- PVB for standard laminates and acoustic upgrades.

- SGP for structural roles (fins, point supports) and stronger post-breakage capacity.

- Choose the Low-E type and specify surface position in your make-up line.

- Confirm compatibility with frit/patterns if decorative control is included.

Require physical samples and a mock-up review under real lighting. Coating color shift surprises are very expensive after procurement.

Step 5 — Detail Critical Zones

Do not treat the façade as one condition. Create zone notes:

- Corners: thickness upgrades, support checks.

- Spandrels: heat stress control + appearance strategy.

- Skylights: laminated safety + drainage details.

- Entrances: impact/security considerations.

This is where good specs get written: not “tempered glass everywhere,” but “glass make-up by zone.”

Step 6 — Validate with Samples, Mock-Ups, and Test Reports

Validation is not bureaucracy; it’s risk control.

- Glass samples (vision + spandrel + frit).

- Visual mock-up review (color, distortion, reflectance).

- Engineering calculations and submittals.

- Performance test plan (air/water/structural) aligned to project requirements.

Water penetration tests like ASTM E331 evaluate resistance under uniform static air pressure differences; that’s why test pressure selection must match wind exposure, not a default number.

How to Write the Glass Specification Line

Copy-Paste Friendly Formats

Below are practical formats you can adapt for your specifications.

1. Glass Make-Up Examples

Use a consistent structure: Thickness + Heat Treatment (A/HS/T) + Interlayer + Special Notes.

Example 1 — Laminated (structural / point-supported direction):

Use when stiffness and post-breakage capacity are priorities (system dependent).

Example 2 — Laminated for acoustics (vision):

Use when sound control is needed and safety requires retention.

2. IGU Line View (Airspace, Gas, Spacer, Coating)

Write the IGU from exterior to interior: Outer lite / cavity / inner lite.

Example — Double IGU with Low-E (typical commercial):

Example — Laminated inner lite IGU (safety + acoustics):

- Warm-edge spacer (if required).

- Visible transmittance and reflectance targets.

- Color range approval.

- NFRC-style language is often used to describe U-factor and SHGC targets consistently, which helps align submittals to measurable expectations.

3. Tolerances and Quality Notes

Instead of vague “high quality,” write specific acceptance criteria:

- Sample approval process (one approved standard retained).

- Color/reflectance tolerance (by supplier capability).

- Visual inspection distance and lighting conditions.

- Allowable distortion criteria (especially for large lites).

Avoid: “No distortion allowed.”

Better: “Visual acceptance based on approved mock-up under defined viewing conditions.”

4. What Submittals Must Include

- Glass make-up schedule by zone (vision / spandrel / corners / skylight).

- Structural calculations and thickness justification.

- IGU warranty language.

- Coating data sheets and sample approval record.

- Sealant compatibility statements (where relevant).

- Test reports and performance documentation language.

Air leakage is typically measured via ASTM E283 method, and water resistance via ASTM E331 method; write your acceptance criteria and pressures clearly so everyone prices the same scope.

Conclusion

Engineering Alignment Over “Premium” Labels

Choosing glass for curtain walls is not about picking a “premium” label. It’s about making the glass do the right job in the right place, inside the real constraints of system type, structural support, performance targets, and façade zones.

⚠️ One Headline Lesson from the Industry

Major curtain wall projects have suffered when glass design assumptions didn’t match real building behavior. The John Hancock Tower reglazing history is a classic reminder that curtain wall glass failures can become a major project story—expensive, public, and avoidable with better early engineering alignment.

For your next project, keep it simple:

- ☑Confirm system type and support condition.

- ☑Lock performance targets (DP, air/water, thermal, acoustic).

- ☑Choose glass make-up by zone.

- ☑Validate with samples, mock-ups, and test planning.

And if procurement is part of your scope, tie this workflow into your internal article:

FAQ

Curtain Wall Glass Selection

1) Do I need laminated glass for every curtain wall?

Not always. But laminated glass is strongly favored when you need post-breakage retention, improved safety, acoustics, or security. Overhead glazing and fall-risk zones commonly push you toward laminated solutions.

2) What’s a safe “default” vision glass build-up for many commercial curtain walls?

A common baseline is a double IGU with Low-E, with heat-strengthened or tempered outer lite and tempered or laminated inner lite depending on safety and acoustics requirements. Always confirm with structural and code needs.

3) PVB vs SGP—when is SGP worth it?

Use SGP when the glass plays a structural role (glass fins, point-supported systems) or when you need stronger post-breakage performance. PVB is often sufficient for standard laminated vision glass and acoustic laminates.

4) Double vs triple glazing—when does triple actually make sense?

Triple glazing is most justified in extreme climates or very aggressive energy targets. But it increases weight and thickness, affecting curtain wall pockets, handling, and cost. Often, a strong double IGU + good frame thermal break achieves the best total value.

5) Why does spandrel glass often look different from vision glass?

Spandrels sit over opaque materials (insulation, back pans) and can experience higher temperatures. Light transmission and backing differences often create visible mismatch. Early mock-up review is critical.

6) What causes IGU fogging most often?

Fogging usually indicates seal failure allowing moisture into the cavity. Common contributors include production process control, edge contamination, handling damage, and installation stress. Require IGU warranty and quality documentation.

7) Which test methods are commonly referenced for curtain wall air and water performance?

Air leakage is commonly measured using ASTM E283. Water penetration resistance under static air pressure is commonly evaluated using ASTM E331. Your project spec determines target pressures and acceptance criteria.

8) How do I prevent “too reflective” façades from causing glare problems?

Use glare and reflection modeling early, especially on concave geometry or high-reflectance coatings. The well-known 20 Fenchurch Street glare issue shows why reflection can become a real-world hazard if not evaluated.

9) What’s the most overlooked part of glass selection?

Zone-based thinking. Corners, spandrels, skylights, and entrances are not the same condition. One make-up for everything often creates risk somewhere.

10) What should I ask the supplier to prove before finalizing glass?

Ask for: glass make-up schedule, calculations, coating data, sample approval record, IGU warranty terms, and performance documentation. Align submittals to consistent rating language (NFRC-style U-factor / SHGC terms are widely used).