🏬 Introduction

In the bustling landscape of modern commercial architecture, the first impression is everything. Whether it is a high-end retail boutique on 5th Avenue or a corporate office lobby in New York, the interface between the public street and the private interior defines the customer experience. This interface is almost always a storefront system.

However, for developers, general contractors, and procurement managers, “storefront” is more than just a window. It is a complex assembly of aluminum framing, high-performance glazing, entrance hardware, and critical waterproofing details.

Get it right, and you have a durable, inviting entrance that drives foot traffic.

Get it wrong, and you face years of storefront system water leakage causes, condensation issues, and expensive repairs.

This comprehensive guide, drawing on APRO’s extensive manufacturing and installation experience, is your definitive resource. We will move beyond the basic storefront system meaning to explore the technical nuances of thermal breaks, storefront system drainage and weep holes explained, and the critical storefront vs curtain wall difference.

By the end of this 7,000+ word deep dive, you will have the knowledge to specify, source, and install a commercial storefront system with absolute confidence.

What Is a Storefront System?

🏢 The Core Definition

A storefront system (also called a storefront framing system) is a non-load-bearing exterior (or interior) glazing-and-framing assembly used mainly at ground-floor commercial areas—think retail façades, mall entrances, restaurant fronts, and office lobbies.

💡 In Other Words…

An aluminum storefront system explained properly is not “just storefront glass.” It’s a full storefront glazing system overview:

- 🔹 Mullions + Transoms

- 🔹 Glass Infill

- 🔹 Pressure Plates + Cover Caps

- 🔹 Gaskets + Sealant

- 🔹 Anchors

- 🔹 Weep/Drainage Details

- 🔹 Door Hardware

That’s why people also search storefront system vs storefront glass—because glass is only one part of the system.

What Does a Storefront System Do? (Its core functions)

👁️ 1. Creates a transparent commercial façade

- 🔹 Gives large display windows and clean sightlines for branding and merchandising

- 🔹 Makes the space feel open and bright (natural daylight)

🛡️ 2. Holds and protects the glass safely

- 🔹 Supports the glazing against wind pressure and daily impacts

- 🔹 Allows proper glass edge clearances, setting blocks, and safe retention (captured or SSG)

☔ 3. Keeps weather out—if detailed correctly

- 🔹 Controls water penetration and manages rain via drainage/weep paths

- 🔹 Controls air infiltration (drafts) through gaskets + sealant continuity

🌡️ 4. Delivers comfort performance (optional but common)

- 🔹 Thermal performance (with thermal breaks + IGU/Low-E)

- 🔹 Condensation resistance (warmer interior frame surfaces)

- 🔹 Acoustic performance (airtightness + laminated/acoustic IGU)

🚪 5. Integrates the entrance doors and hardware

- 🔹 Provides a stable frame for doors, sidelites, transoms

- 🔹 Supports heavy-traffic hardware (closers, pivots/floor springs, locks) and alignment over time

📐 6. Manages tolerances and movement

- 🔹 Connects to concrete/steel structure via anchors and shims

- 🔹 Allows building/thermal movement without cracking glass or tearing sealant

🔒 7. Can add safety/security features

- 🔹 Impact-rated or forced-entry-resistant configurations

- 🔹 Laminated safety glass for fall protection or smash-and-grab risk

Where Is a Storefront System Used?

If you’re specifying a storefront system for retail storefront projects, you’ll usually see it in these common application zones:

🛍️ Street retail / mall perimeter façades (continuous bays)

A storefront framing system for commercial building façades is common along street-facing shop lines. Designers like it because it offers a consistent “brand-ready” grid, good transparency, and easy integration with signage and lighting.

🚪 Store entrances (door + sidelites + transoms)

A storefront system for shopping mall entrances usually means an entrance door package plus fixed glass panels. This is where the storefront entrance system definition becomes very practical: the system is doing façade + door integration at the same time.

🖼️ Display glazing / storefront windows

For storefront system for storefront windows (display glazing), the goal is often maximum visibility and minimal visual obstructions. That puts pressure on sightlines, glass size, and how clean the cap/cover looks.

🍽️ Restaurants and hospitality fronts

A storefront system for restaurant front designs often need comfort (air leakage control), easy cleaning, and durable door cycles. Restaurants also tend to have heavy traffic—door hardware becomes a big deal.

🏢 Office lobbies and commercial entry zones

A storefront system for office lobby entrance is a sweet spot: high transparency, moderate height, strong door coordination, and a clean interior finish.

🛋️ Tenant fit-out and interior storefronts

An interior storefront system meaning is basically the same concept—glass and framing used as an interior “front” (often for store-in-store or office suites). You’ll see interior storefront system for tenant fit out in malls, airports, office towers, and mixed-use projects.

🔄 Ground-floor transition between curtain wall and storefront

It’s also common to use a storefront system for curtain wall transition at ground floor—for example, curtain wall above, storefront at the podium/retail level, because storefront is often easier for doors, service access, and fast replacement.

✅ One-line reality check: Storefront is typically favored for lower heights, faster installation, and strong door integration—fast install, door-heavy, ground-floor-friendly.

What Are the Main Components of a Storefront Framing System?

If you’re looking up storefront framing system components or storefront system parts (mullion transom pressure plate cover cap), here’s the practical breakdown—with what each part really controls on site.

🏗️ Aluminum frame: mullions and transoms

- 🔹 Mullions (vertical members) and transoms (horizontal members) create the grid.

- 🔹 The storefront mullion sizes and types (depth and reinforcement options) heavily influence structural capacity and deflection.

- 🔹 The narrow stile storefront system meaning usually refers to thinner-looking sightlines—great aesthetically, but it demands careful structural checks.

Why it matters: sightline and depth control both looks and “how much wind load can this take.”

🖼️ Glazing and infill: glass, spandrel, or panels

When buyers ask what glass is used in storefront systems, the answer is: it depends on performance targets and safety requirements.

- 🔹 Common infills include tempered, laminated, IGU, or hybrid assemblies.

- 🔹 There can also be opaque infill zones (spandrel glass, insulated backpans, or decorative panels), which is where storefront spandrel glass vs backpan becomes relevant.

🔩 Captured glazing hardware: pressure plate + cover cap

A captured storefront system (often called a pressure plate storefront system or cap cover storefront system) uses:

- 🔹 A pressure plate to mechanically clamp the glass

- 🔹 A cover cap to hide the plate and create the exterior appearance

Why it matters: captured systems are forgiving and serviceable—great for real-world building operations.

🧪 Structural silicone glazing (SSG)

A structural silicone glazed storefront (SSG storefront system) bonds glass to the frame with silicone (with mechanical retention details per system rules).

- 🔹 A 2-sided SSG storefront system typically has silicone on two sides, with caps on the other two.

- 🔹 A 4-sided SSG storefront system is the cleanest look, but the most sensitive to QA/QC and fabrication discipline.

🛡️ Seals: gaskets and sealant joints

The storefront system glazing gasket types (EPDM profiles, wedge gaskets, etc.) and sealant details control air/water performance and long-term durability.

Failures here often show up as storefront system sealant joint failure or “mysterious leaks that only happen in wind-driven rain.”

💧 Drainage and pressure equalization

If you only remember one phrase, remember this one: storefront system drainage and weep holes explained is not a side detail—it’s the difference between dry building and call backs forever.

- 🔹 Weep holes, internal gutters, and pressure-equalized cavities are what make a storefront behave like a rain screen.

- 🔹 The phrase storefront system rain screen / pressure equalization (storefront) is exactly the concept you want to build into your details.

⚓ Anchors and brackets

Storefront system anchorage details tie the frame to concrete or steel structure. This is where you manage:

- 🔹 Wind load transfer

- 🔹 Tolerances and shimming

- 🔹 Storefront system movement allowance (expansion, inter-story drift assumptions at the ground floor, and thermal movement)

🚪 Entrance doors and hardware

The storefront entrance door system hardware is often the highest-maintenance part of the entire storefront.

- 🔹 Think commercial storefront door hardware selection, floor springs, closers, pivots, locks, and panic devices.

✅ Bottom line: a storefront system is a coordinated kit. If you try to buy “glass” and “frame” separately without a clear system approach, you risk mismatched tolerances, weak drainage logic, and warranty gaps.

Common Types of Storefront Systems

If you’re mapping keywords like stick-built storefront system, preassembled storefront system, thermal storefront system, and non-thermal storefront system, here’s the clearest classification.

🏗️ 1) By build method: stick-built vs preassembled

- 🔹 Stick-built storefront system: most common; frame members are assembled on site, glass installed afterward. Flexible and cost-effective.

- 🔹 Preassembled storefront system: more work done in the factory (better consistency), faster site time, but demands accurate opening measurements and logistics planning.

🖼️ 2) By glazing capture: captured vs SSG

- 🔹 Captured storefront system: pressure plate + cap/cover. Reliable, serviceable.

- 🔹 SSG storefront system (2-sided or 4-sided): maximum transparency, higher QA/QC needs, more critical silicone and surface prep control.

🌡️ 3) By thermal construction: thermal break or not

This is where buyers ask do storefront systems need thermal breaks.

- 🔹 Non-thermal storefront system: cheaper, but more prone to cold-bridge discomfort and storefront system condensation problem in colder climates or humid interiors.

- 🔹 Thermally broken storefront system: includes a thermal barrier in the profile. The thermally broken storefront system benefits are comfort, condensation resistance, and energy performance—especially when codes or building owners demand it.

(You’ll also see “storefront thermal break vs non-thermal storefront” comparisons in value engineering meetings all the time.)

🛡️ 4) By security and performance features

- 🔹 Impact rated storefront system

- 🔹 Forced entry resistant storefront system

- 🔹 Fire-rated storefront assemblies (must be certified as a system; not just “fire glass”)

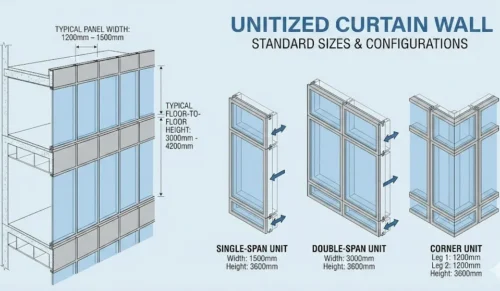

Storefront vs. Curtain Wall vs. Window Wall: What’s the Difference?

| Item | Storefront | Curtain Wall | Window Wall |

|---|---|---|---|

| Structural definition | Non-load-bearing aluminum framing + glazing system, typically engineered for lower-height commercial fronts | Non-structural exterior wall system transferring wind loads to the building structure; engineered for larger/taller façades | Window units installed slab-to-slab; more like repeated windows than a continuous façade system |

| Typical use | Retail shopfronts, mall entrances, restaurant fronts, office lobbies (door-heavy zones) | Mid/high-rise façades, large continuous building envelopes | Multi-story buildings with repetitive window bands (residential/hotel/office) |

| Where it’s installed | Mostly ground floor / podium | Across the façade, often upper floors and tall elevations | Each floor between slabs (from level to level) |

| Installation method | Usually stick-built on site; glazing and doors integrated | Stick-built or unitized (prefab panels) on larger projects | Repeating window units installed per floor |

| Visual effect | Clean shopfront grid; can be captured or SSG for more glassy look | Most “continuous façade” look; high design flexibility | Looks like stacked windows; slab lines often visually define the façade |

| Cost (typical) | Often lower for ground-floor zones; doors/hardware and detailing can add cost | Often higher due to engineering/testing and complexity (especially unitized) | Often cost-effective for repetitive floors; depends on slab-edge/detail quality |

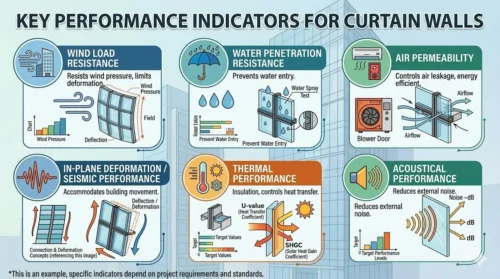

Storefront Systems Key Performance Metrics That Matter Most

When you’re specifying storefront, the performance section is where disputes are prevented—or born.

These are about storefront system air infiltration requirements, storefront system water penetration resistance, storefront system structural performance (deflection), and storefront system performance testing requirements.

🏗️ Structural performance: wind load and deflection

- 🔹 Storefront system design pressure is the project wind load target.

- 🔹 Deflection limits (often expressed as span/___) control glass edge stress, gasket performance, and visual waviness.

- 🔹 Testing and calculations must match the system and glass configuration.

- 🔹 A key reference point for structural testing is ASTM E330/E330M, a standard test method for structural performance under uniform static air pressure difference.

💨 Air infiltration (leakage)

Air leakage drives comfort complaints, energy loss, and condensation risks.

- 🔹 For lab testing methods, ASTM E283 is a common standard test method used to determine air leakage rates of exterior windows, curtain walls, and doors under specified pressure conditions.

- 🔹 If you’re in ISO/EN ecosystems, ISO air permeability testing exists too. ISO describes a test method to determine air permeability for assembled windows and pedestrian doorsets.

☔ Water penetration resistance

Water resistance is often the #1 punch list category.

- 🔹 A foundational lab method is ASTM E331, which covers resistance to water penetration when water is applied with a static air pressure difference.

- 🔹 For dynamic pressure water testing (more like gusty rain), industry methods such as AAMA 501.1 are also used in certain QA/QC or forensic contexts.

🌡️ Thermal performance: U-factor and SHGC

To talk thermal performance clearly, owners and codes often rely on standardized rating procedures.

- 🔹 NFRC 100 is used to determine fenestration product U-factor (thermal transmittance).

- 🔹 NFRC 200 is commonly referenced for calculating/rating SHGC and visible transmittance under standard conditions.

These are exactly the “industry data standards” that keep energy discussions measurable instead of emotional.

🌫️ Condensation resistance

Storefront system condensation resistance is not just glass—it’s frame thermal bridging, interior humidity, air leakage, and thermal breaks.

🔇 Acoustic performance (STC/OITC)

- 🔹 Storefront system acoustic performance STC OITC matters for street retail in loud areas and office lobbies near traffic.

- 🔹 A simple truth: acoustic outcomes usually come from glass makeup (laminated acoustic interlayers, asymmetric thickness, IGU cavity), and airtightness—not “just thicker glass.”

🛡️ Security: impact and forced entry

- 🔹 Impact rated storefront system (especially in coastal storm regions)

- 🔹 Forced entry resistant storefront system (high-theft retail)

Thermal Breaks, Energy, and Condensation: How to Decide

Buyers usually search best Low-E glass for storefront system, storefront system U-factor SHGC explained, and how to prevent condensation on storefront glass because these three items drive comfort complaints and rework risk.

📊 U-factor vs SHGC

- 🔹 U-factor = how fast heat escapes through the storefront (frame + glass). Lower U-factor = better insulation and warmer interior surfaces.

- 🔹 SHGC = how much solar heat passes through the glass. Lower SHGC = better solar control (less overheating and glare).

🌡️ Do storefront systems need thermal breaks?

- 🔹 Choose a thermally broken storefront system when you have cold winters, humid interiors (restaurants/malls), strict energy targets, or any history of “sweating frames.”

- 🔹 A non-thermal storefront system can work in mild climates with controlled indoor humidity—but it has higher condensation risk if air leakage or humidity is high.

💧 How to prevent condensation on storefront glass (the 3 levers)

- 🔹 Warmer interior surfaces: thermal break frames + better IGU (Low-E, gas fill).

- 🔹 Reduce edge condensation: consider a warm edge spacer on the IGU.

- 🔹 Control moisture + air leakage: keep indoor RH reasonable in winter and seal the perimeter properly—air leaks often cause “localized sweating.”

✅ Best Low-E glass for storefront system (how to pick quickly)

- 🔹 Heating-dominated climates: prioritize lower U-factor (comfort + condensation control).

- 🔹 Cooling-dominated climates: prioritize lower SHGC (solar control), while keeping enough visible light for retail display.

- 🔹 Mixed climates: pick a balanced Low-E and lean on a thermal-break frame if condensation risk is a concern.

Glass Configurations: IGU vs Laminated vs Tempered (and How to Choose)

🔍 What glass is used in storefront systems?

- 🔹 Tempered (safety, impact resistance)

- 🔹 Laminated (fall protection, security, acoustic)

- 🔹 IGU (insulation, comfort, condensation control)

- 🔹 Hybrids: laminated IGU (both security + energy)

🚀 Step-by-step: choose glass based on risk

1️⃣ Start with safety requirements

If fall protection, overhead risk, or smash-and-grab security is a concern, laminated is often the right base.

2️⃣ Add energy targets

If you need thermal performance, IGU is usually required. Then decide whether one lite must be laminated.

3️⃣ Consider panel size

For large display panels, storefront glass thickness for large panels becomes structural and deflection-driven. Don’t guess—calculate.

4️⃣ Decide acoustic strategy

Acoustic laminated glass + good airtightness often beats “random thickness increases.”

5️⃣ Lock down color and coating

Storefront glass color consistency control must be defined: same supplier, same coating family, same batch control strategy, and sample approvals.

Critical Details & Nodes (Where Projects Succeed or Fail)

Success is in the details. Storefront system shop drawing details checklist must include these nodes.

💧 The Sill (The #1 Leak Zone)

- 🔹 Sill Pan: The storefront sill flashing detail must be continuous, with end dams sealed watertight.

- 🔹 Weeps: Storefront weep hole design must not be blocked by caulk.

- 🔹 Shim Space: Must allow water to flow under the glass setting blocks.

🏗️ Head & Jamb

- 🔹 Head Receptor: Used to accommodate slab deflection. The storefront head slides inside a U-channel to allow the building to move without crushing the frame.

- 🔹 Jamb: Storefront head jamb sill details must show the continuity of the air barrier (caulk joint) to the rough opening.

📐 Corners & Expansion Joints

- 🔹 Corners: Storefront system corner detail (90-degree post or brake metal) is complex for thermal breaks.

- 🔹 Expansion: Aluminum expands. Storefront expansion joint detail (split mullions) is required every 20-25 feet to prevent buckling.

🚪 Door Thresholds

- 🔹 Water vs. ADA: Storefront door threshold waterproofing detail is a trade-off. Low ADA thresholds (1/2″ max) are hard to waterproof.

- 🔹 Sweep: Use a quality door sweep to stop wind-driven rain.

Common Problems & How to Avoid Them (The “Pitfalls”)

Avoiding storefront water leakage causes requires vigilance.

💧 Why Do Storefronts Leak?

- 🔹 Cause 1: Storefront leaks at sill (storefront sill pan detail) failure. The end dams were not sealed, or the splice joints in the flashing leaked.

- 🔹 Cause 2: Storefront system sealant joint failure. The perimeter caulk failed due to poor surface prep.

- 🔹 Cause 3: Storefront system glazing gasket types shrinkage. Cheap vinyl gaskets shrink, leaving gaps in the corners. Storefront perimeter sealant best practices dictate using high-quality silicone.

🌫️ Why Does Glass Fog or Mold Appear?

Cause:

Storefront system condensation problem. Using a non-thermal storefront system in a cold climate creates a cold bridge.

Fix:

Use a warm edge spacer for storefront IGU and a thermally broken frame. How to prevent condensation on storefront glass starts with the spec.

🚪 Why Do Doors Sag?

Cause:

Storefront door sagging causes are usually undersized hinges or loose tie-rod construction in the door leaf.

Fix:

Use heavy-duty pivots and welded corner doors for high-traffic areas.

🎨 Why Is The Glass Color Wrong?

Cause:

Storefront glass color consistency control. Different batches of Low-E coating can look slightly different.

Fix:

Order all glass from one batch run.

Site experience: fixing a wind-driven rain storefront leak (Canada, 2023)

🏗️ The Context: A Frustrating Handover

In 2023, we were brought into a storefront system project on Canada after a frustrating handover story.

The client had originally hired another storefront provider to supply and install the system. For the first few months, everything looked fine—but about six months after installation, the tenant began reporting drainage issues and intermittent leakage, especially during heavy, windy rain.

The client did what any owner would do: they contacted the original storefront provider. Unfortunately, the response was worse than “no help.” The provider refused to offer any warranty support and even verbally insulted the client, leaving the owner with a leaking storefront and nowhere to turn.

Through a friend’s introduction, the client reached out to us.

🚀 Our first move: activate local support—fast

Because the project was in Canada, we immediately coordinated with our local dealer in the area. We shared the project background, photos, and the reported symptom (“leaks during wind-driven rain”), then arranged for our distributor’s service team to visit the site, inspect the sill condition, and perform troubleshooting in a controlled way.

We treated it like a real storefront diagnostic—not a “sealant smear” job.

🔍 What our distributor found on site

After opening up key areas at the sill and checking the drainage logic, the issue became clear:

The previous storefront provider did not properly handle the sill drainage during installation.

- 🔹 The sill pan / drainage setup was either incomplete or incorrectly configured, which meant:

- 🔹 Water entering the glazing pocket could not drain outward effectively

- 🔹 During heavy rain and wind pressure, water built up inside the sill cavity

- 🔹 With no reliable exit route, water took the path of least resistance—into the interior

In other words: the system wasn’t failing because “water got in.” It failed because the ‘get out’ part of drainage was never properly built.

🛠️ How our distributor fixed it (step-by-step)

- Opened up the sill area strategically: They removed limited sections of trim/cover components only where needed to expose the drainage path—minimizing disruption to the tenant.

- Verified drainage components and checked the actual path: They confirmed where water was collecting, checked for blocked/incorrect weeps, and traced whether the drainage route truly connected to the exterior.

- Corrected the sill drainage configuration: Where the previous installer had missed or misapplied drainage detailing, our distributor rebuilt the intended flow path so water could move outward instead of pooling.

- Cleaned and re-established weep function: Any debris, sealant blocking, or dead-ended outlets were cleared so the weeps became “live” again.

- Reworked perimeter sealant only where it mattered: Instead of sealing everything shut, they repaired joints with proper sealant geometry and backer rod, restoring a durable, flexible joint without trapping water.

- Re-tested under controlled water spray: They repeated the water test and confirmed stable drainage and zero interior leakage, including under conditions simulating wind-driven rain.

💬 How we handled communication with the client

We documented everything with photos and a simple explanation the owner could trust:

No public trade-blaming. Just clear mechanism + clear corrective scope + proof by re-test.

✅ The result: trust, then repeat work (2023–2026)

After the repair, the client’s view changed completely:

- 🔹 They saw fast response through our local distributor

- 🔹 They saw a solution based on system behavior, not patching

- 🔹 They got documentation and a verified water test result

From that point on, the client strongly (recognized) our reliability. Up to 2026, we have partnered again on four additional projects, covering both curtain wall and storefront systems—not because we promised the most, but because we proved we could solve the root cause and stand behind the outcome.

What to Include in Your RFQ / PO (Buying Guide)

To get accurate quotes and avoid change orders, use this storefront system RFQ checklist.

📝 System Specification (System Spec)

- 🔹 Dimensions: Storefront mullion sizes and types (e.g., 2″ x 4-1/2″).

- 🔹 Thermal: Thermally broken storefront system required? Yes/No.

- 🔹 Type: Captured storefront system or SSG storefront system?

- 🔹 Finish: Clear Anodized vs. Dark Bronze vs. Custom PVDF Color.

🎯 Performance Targets

- 🔹 Wind Load: Storefront system design pressure (e.g., +30/-30 psf).

- 🔹 Water: Storefront system water test procedures required? (e.g., 12 psf static).

- 🔹 Thermal: Max U-factor (e.g., 0.38).

🧱 Material & Workmanship

- 🔹 Aluminum: Alloy 6063-T5 or T6.

- 🔹 Sealant: Dow Corning 795 or Tremco Spectrem 2.

- 🔹 Gaskets: EPDM only (no vinyl).

📦 Submittals & Deliverables

- 🔹 Drawings: Storefront system shop drawing details checklist.

- 🔹 Calcs: Structural calculations stamped by a PE.

- 🔹 Samples: Storefront system mockup requirements (corner sample).

- 🔹 Warranty: Storefront system warranty typical terms (e.g., 10 years on finish, 5 years on install).