Introduction

The Strategic Edge of Unitized Curtain Walls

In the high-stakes world of commercial construction, the building envelope is the critical path.

It defines the aesthetic, manages the energy performance, and often dictates the schedule of the entire project. Among the various façade options available, the unitized curtain wall stands out as the premier solution for high-rise and fast-track construction.

Definition vs. Strategic Reality

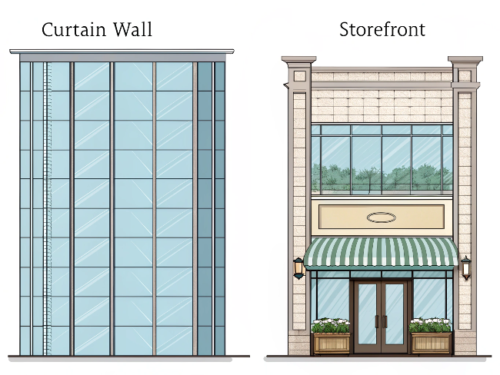

“According to Wikipedia, a curtain wall is defined as an outer covering of a building in which the outer walls are non-structural.”

However, for the modern developer or General Contractor, a unitized curtain wall is much more than a definition; it is a strategic tool for risk management and schedule acceleration.

About This Guide

Drawing from over a decade of manufacturing experience at APRO, this guide will take you from the basic unitized curtain wall meaning to the complex nuances of sourcing, cost drivers, and quality control.

Whether you are an architect detailing a unitized curtain wall section detail or a procurement manager building a unitized curtain wall specification, this is your roadmap.

🏗️What is a Unitized Curtain Wall?

The Meaning of Unitized Curtain Wall

At its core, what is a unitized curtain wall? It is a prefabricated curtain wall system composed of large, pre-assembled, glazed, and sealed panels (units) that are manufactured in a factory and shipped to the construction site for immediate installation via crane or hoist. Unlike traditional methods, unitized curtain wall assembly happens entirely off-site in a controlled environment.

When we talk about unitized curtain wall system explained, we are describing a shift from “construction” to “manufacturing.”

The unitized curtain wall definition architecture relies on the concept that building parts should be built like cars: on an assembly line, with rigorous quality checks, before ever reaching the chaotic job site. This makes it a distinct modular curtain wall system compared to field-assembled options.

In the UK and other regions, you might see it spelled as unitised curtain wall, but the unitized facade system principles remain identical. It serves as the skin of the building, hanging off the main structure, transferring wind and gravity loads back to the floor slabs.

⚖️Pros and Cons of Unitized Curtain Wall

Every system has trade-offs. Understanding the unitized curtain wall vs panelized curtain wall nuances helps in making the right choice.

✅ Advantages of Unitized Curtain Wall

- •Speed of Installation: The unitized curtain wall schedule advantages are massive. Since fabrication happens concurrently with the site concrete pour, the façade can be enclosed 30-50% faster than stick systems.

- •Quality Control: Unitized curtain wall factory quality control is superior. Applying structural silicone in a climate-controlled factory prevents the dust and humidity issues common on sites.

- •Reduced Site Labor: Unitized curtain wall labor savings are significant. You need fewer workers hanging off the side of the building, reducing insurance risks and safety hazards.

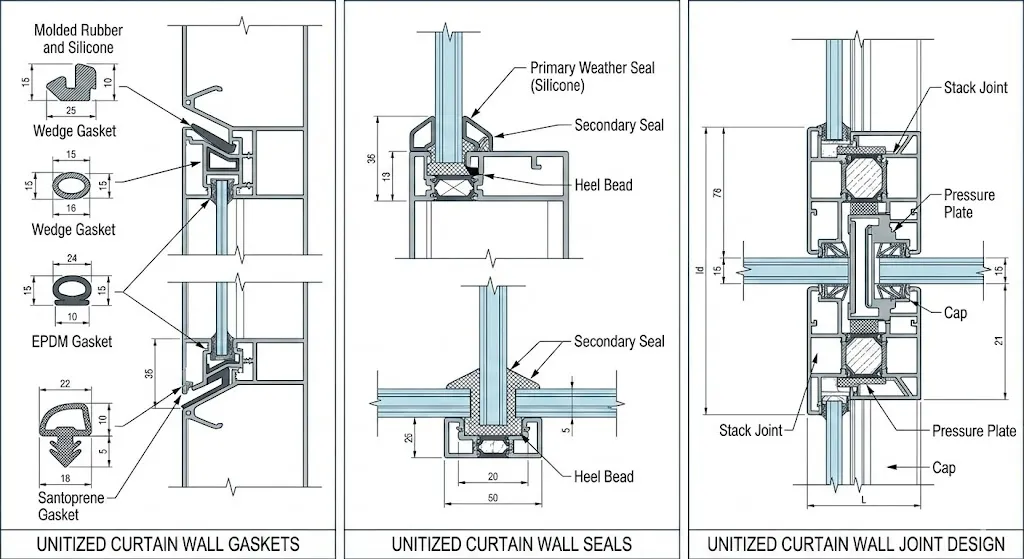

- •Movement Capability: The unitized curtain wall stack joint is designed to handle seismic drift unitized curtain wall and thermal expansion better than rigid stick systems.

⚠️ Disadvantages of Unitized Curtain Wall

- •Higher Upfront Cost: The unitized curtain wall cost vs stick system analysis often shows a higher initial price tag due to shipping “air” (bulky frames) and specialized equipment.

- •Design Inflexibility: Once the unitized curtain wall system design is frozen and dies are cut, late changes are incredibly expensive. Unitized curtain wall change order management is difficult.

- •Logistics: Unitized curtain wall site logistics require heavy cranes and large staging areas for the stillages, which can be tricky on tight urban sites.

- •Joint Aesthetics: The unitized curtain wall interlocking joint means you have double mullions (a split mullion) at every grid line, creating a wider sightline compared to stick systems.

⚙️How Unitized Curtain Wall Works

1. Basic Idea: Panel + Stack Joint + Anchors

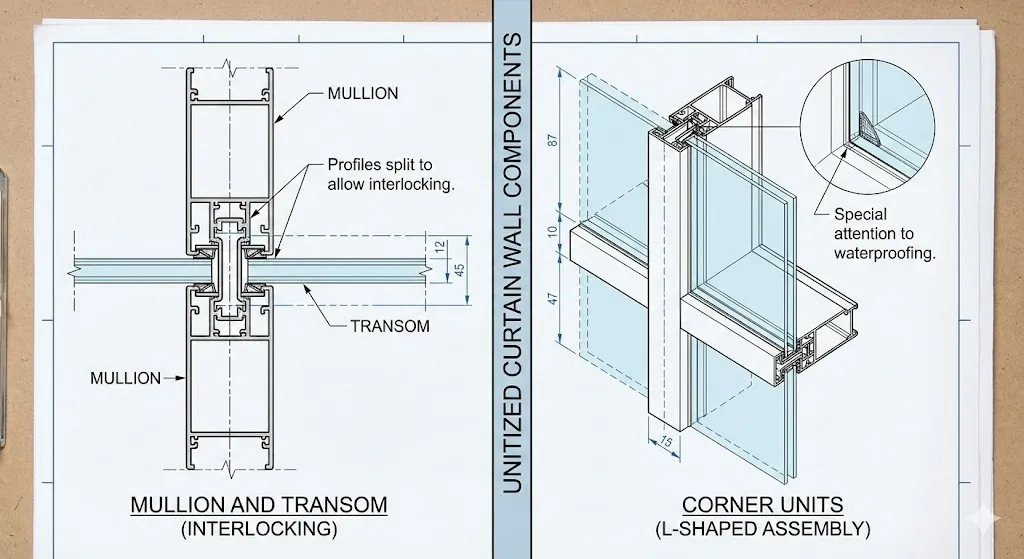

How does a unitized curtain wall work? It relies on a “male/female” interlocking system. Each unitized curtain wall panel has a split mullion. When installed, the male mullion of one unit mates with the female mullion of the adjacent unit. The unitized curtain wall stack joint (horizontal) allows the units to stack on top of each other while accommodating floor movement.

2. Load Path Explained (Wind, Dead Load, Movement)

The unitized curtain wall details must account for three primary loads:

- Dead Load: The weight of the glass and aluminum is transferred via the unitized curtain wall anchor bracket to the floor slab.

- Wind Load: The wind pressure pushes on the glass, transfers to the mullions, and then to the anchors. High wind curtain wall design requires robust reinforcement.

- Movement: Interstory drift curtain wall capacity is handled by the sliding joints between units.

3. Movement Management: Drift + Thermal Expansion

A building is never static. Curtain wall movement joint design in unitized systems is critical. The gap between the units (the stack joint) is filled with gaskets that allow the aluminum to expand in the summer and contract in the winter without breaking the seal or the glass. During an earthquake, the units slide past each other to prevent structural damage.

4. Water Management Concept: Pressure Equalized Rain Screen

The rainscreen principle curtain wall is the secret to weatherproofing. Instead of trying to seal water out perfectly (which fails), unitized systems use a pressure equalization chamber curtain wall.

Wind pressure pushes water into joints. By creating a chamber inside the joint that is vented to the outside, the air pressure inside the joint equals the outside pressure. Without a pressure differential, water isn’t “sucked” in. Any water that does enter drains out via weep holes. This is far superior to a “face-sealed” system.

🧩Unitized Curtain Wall Components

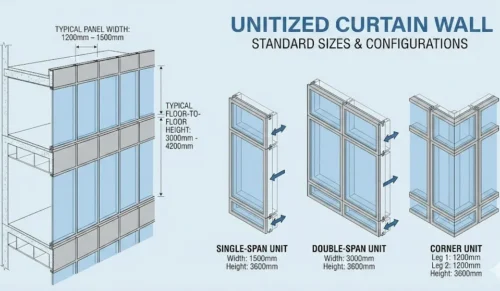

1. Unitized Panel/Frame (Mullion, Transom, Corner)

The skeleton of the system is the unitized curtain wall frame.

- Mullion and Transom: The vertical (mullion) and horizontal (transom) members create the grid. In a mullion and transom unitized curtain wall, these profiles are split to allow interlocking.

- Corner Units: A unitized corner unit curtain wall is often pre-assembled as a single L-shaped piece or mitered on-site, requiring special attention to waterproofing.

2. Vision Glass vs Spandrel (Back Pan, Insulation, Fire)

- Vision Glass: The transparent part.

- Spandrel: The opaque area covering the floor slab. The spandrel panel unitized curtain wall often uses spandrel glass curtain wall detail (ceramic frit or back-painted).

- Back Pan: A back pan spandrel curtain wall (metal sheet) holds the unitized curtain wall insulation detail (mineral wool) in place, providing thermal resistance and fire protection.

3. Gaskets, Seals, and Joint Design

- Gaskets: Unitized curtain wall EPDM gasket profiles are the first line of defense.

- Sealants: The unitized curtain wall sealant joint (structural silicone) bonds the glass to the frame. Curtain wall silicone compatibility testing is mandatory to prevent chemical failure.

- Air/Water Seal: The unitized curtain wall interlocking joint relies on “chicken head” gaskets and wiper seals to maintain the air barrier.

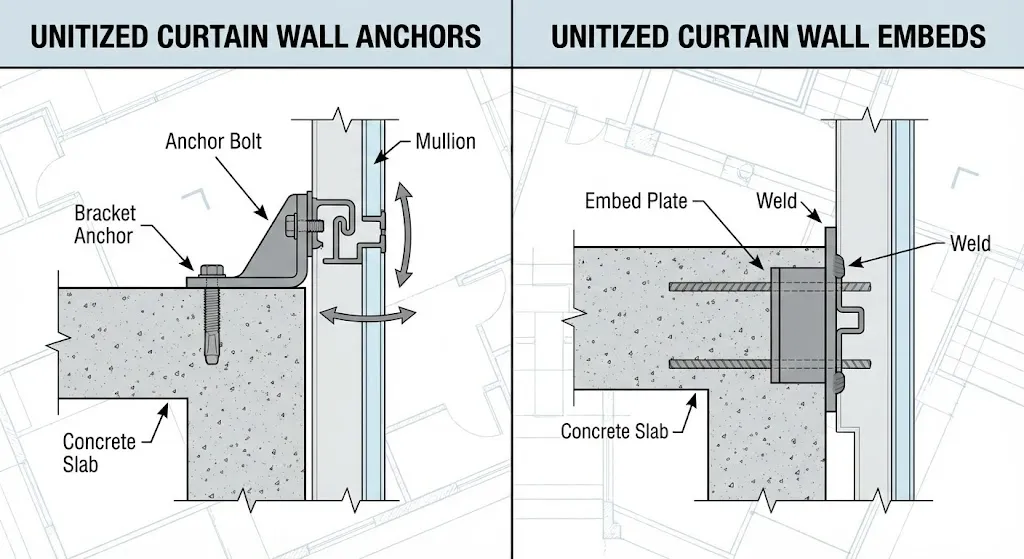

4. Anchors and Embeds (Edge Conditions + Tolerance)

The connection to the building.

- Anchors: The unitized curtain wall anchor bracket is typically aluminum or steel.

- Embeds: Curtain wall embed plates tolerance is a major site headache. If the concrete team places the embeds off by 2 inches, the curtain wall anchors must have enough unitized curtain wall bracket adjustment (3-way adjustability) to compensate.

5. Thermal Break Strategy (Condensation & U-value)

Why is a thermal break unitized curtain wall essential? Aluminum conducts heat efficiently. Without a polyamide thermal break curtain wall strip separating the interior and exterior metal, you get curtain wall thermal bridging. This leads to heat loss (poor U-value) and curtain wall condensation risk on the interior frame during winter.

6. Optional Modules (Vents, Sunshades, BIPV)

Modern systems are multifunctional.

- Windows: Unitized curtain wall with operable windows (like parallel opening vents) allow natural ventilation. Trickle vent curtain wall options provide passive airflow.

- Shading: Unitized curtain wall sunshade integration helps reduce solar heat gain. Curtain wall shading devices are bolted directly to the mullions.

- Energy: BIPV unitized curtain wall (Building Integrated Photovoltaics) turns the façade into a power plant using a photovoltaic curtain wall system.

⚖️Unitized Curtain Wall vs Stick Curtain Wall (Quick Comparison)

If you’re deciding between unitized vs stick curtain wall, anchor the decision in schedule + tolerance + change risk, not only in $/m².

| Factor | Unitized curtain wall system | Stick built curtain wall system |

|---|---|---|

| Installation method | Hoist-and-hang units (unitized curtain wall erection) | Assemble on-site (stick curtain wall installation) |

| Speed | Faster enclosure cycle; predictable sequence | Slower; more weather-dependent |

| QA/QC | Factory controlled; repeatable checks | More field variability |

| Tolerance management | Requires survey + bracket adjustment strategy | Can “absorb” more variability but increases rework risk |

| Change orders | Expensive after fabrication begins | More flexible late, but can create site chaos |

| Logistics | Heavier site logistics + crane planning | Less bulky shipping; more onsite labor |

| Best fit | High-rise, repetition, tight schedule | Smaller façades, complex field conditions, frequent change |

📊Performance Metrics Buyers Care About

1. Airtightness

Unitized curtain wall air leakage is tested per curtain wall ASTM testing standards (E283). The unitized curtain wall air permeability must be low to reduce HVAC loads.

2. Water Penetration Resistance

Unitized curtain wall water penetration is the #1 failure mode. The curtain wall rain penetration stack joint design is critical. We aim for high static and dynamic water resistance (e.g., 15 psf).

3. Thermal Performance

Unitized curtain wall U-value measures heat loss. Curtain wall SHGC glazing measures solar heat gain. Together, they define the thermal performance unitized curtain wall.

4. Acoustic Performance

Curtain wall sound transmission class STC measures noise blocking. Using laminated IGU curtain wall acoustics improves performance near airports or highways.

5. Fire & Smoke Details

The curtain wall firestop at slab edge (safing) prevents fire from jumping floors. The perimeter fire containment system curtain wall (PFCS) must be tested and listed (e.g., UL rated). Curtain wall fire and smoke protection is a life-safety issue.

6. Structural Behavior (Wind/Seismic)

In a hurricane rated curtain wall system, the glass must resist impact and high pressures. Seismic drift unitized curtain wall capability ensures the façade stays on the building during an earthquake.

🏗️Typical Unitized Curtain Wall Installation Process (Step-by-Step)

Step 1: Pre-install preparation

(Survey, embed verification, mockups, release drawings)

- As-built survey of slab edges: Confirm slab edge tolerance issues, embed locations, and real dimensions. Output: survey report + deviation map + “go/no-go” thresholds.

- Embed plate and anchor verification: Check curtain wall embed plates tolerance against shop drawings. Decide adjustment ranges and shim strategies early.

- Performance mock-up plan: (curtain wall performance mock-up / unitized curtain wall mockup testing). Confirm whether the project requires curtain wall laboratory testing or site testing. Lock the testing matrix early—late changes cause rework.

- Release drawings and manufacturing freeze: This is where unitized projects either become smooth… or become expensive.

Step 2: Factory stage

This is where unitized wins—if your factory quality plan is real. Factory checkpoints we insist on in a unitized curtain wall QA/QC checklist:

- Profile dimensional checks (critical for unitized curtain wall details at joints)

- Thermal break placement verification (polyamide continuity)

- Gasket hardness and fit checks

- Sealant prep verification (including compatibility controls)

- IGU edge condition check (avoid IGU edge damage curtain wall)

In one project, our production team noticed that stack joint engagement felt inconsistent during dry-fit checks. The units would “seat,” but the interlocking joint didn’t snap in with the same resistance across batches. That’s a classic early warning sign for future unitized curtain wall leak at stack joint or gasket failure.

- Problem: A small but repeatable deviation in a profile batch and a gasket batch that was slightly stiffer than the approved sample.

- Action: We stopped the line, quarantined the batch, and ran a controlled fit-up test. We negotiated a split solution: ship only verified batches and rework the deviating units.

- Result: We resumed production only after restoring consistent engagement forces. The client kept the schedule and avoided downstream rework.

Step 3: Site logistics

(Receiving, staging, lifting plan)

- Receiving inspection: Check packaging, corner protection, and glass condition. Log damage immediately; do not “wait until install.”

- Staging and sequence planning: (unitized curtain wall site logistics). Units must be staged in installation order. Avoid double-handling (that’s where glass breaks).

- Unitized curtain wall lifting plan: Define pick points, lifting frames, tag line control, wind limits, and exclusion zones. Confirm crane time cost assumptions.

Step 4: Installation

(Anchors, hanging, alignment, joint closure)

- Set and verify anchor brackets: (unitized curtain wall field adjustment). Confirm bracket adjustment range and lock-off.

- Hoist and hang the first reference unit: Establish a baseline line/level.

- Install adjacent units and check stack joint engagement: Never force a joint “because the crane is waiting.”

- Close joints and verify gasket continuity: Corner zones are where failures hide.

- Perimeter closure and sealant application: Use approved primers; keep records.

Step 5: Post-install

(Field testing, punch list, replacement procedure)

- Field testing: Unitized curtain wall field testing may include curtain wall air infiltration test and curtain wall onsite water test depending on project spec.

- Punch list: Curtain wall punch list closeout should track issues by elevation + unit number.

- Replacement procedure: Unitized curtain wall replacement procedure must be planned before the first unit goes up (crane access, removal path, spare units strategy).

⚠️Common Failure Points (And How to Prevent Them)

🏭 Factory Experience (Production Floor)

“We once encountered a recurring issue with sealant incompatibility curtain wall components. A client specified a particular EPDM gasket setting block that, unknown to us, contained plasticizers that reacted with the structural silicone.”

The silicone wasn’t curing properly at the contact points, leading to a potential adhesion failure.

We caught this during our routine ‘peel adhesion test’ in the factory lab before shipping any units. We halted production and contacted the sealant manufacturer.

We switched to a silicone-compatible setting block and re-tested. We also implemented a mandatory compatibility test report for every new material combination in our BOM (Bill of Materials). This internal factory action prevented a catastrophic failure on site.

1. Stack Joint Leakage

Unitized curtain wall leak at stack joint interfaces is common.

- Cause: Debris in the gutter or missing “chicken head” gaskets.

- Prevention: Strict QC on the unitized curtain wall stack joint assembly.

2. Misalignment and “Read-Through”

- Cause: Poor unitized curtain wall field adjustment or anchor setting.

- Prevention: Use a jig for anchor setting and verify with 3D scanning.

3. Sealant Incompatibility

Silicone weatherseal failure curtain wall happens when materials react chemically.

- Prevention: Always perform curtain wall silicone compatibility testing (ASTM C1087).

4. Condensation Issues

Curtain wall thermal bridge condensation occurs if the thermal break is bridged.

- Prevention: Continuous unitized curtain wall insulation detail and verifying the polyamide thermal break curtain wall integrity.

5. Glass Breakage

Thermal stress glass breakage curtain wall or curtain wall glass breakage handling is a risk.

- Prevention: Heat-strengthen glass and ensure edges are polished (reduce IGU edge damage curtain wall).

🤔When Should You Choose a Unitized Curtain Wall?

✅ Best-fit criteria

Unitized is usually the right call when you have:

- Height and repetition: (high-rise, hotels, office towers).

- Tight schedule: (fast dry-in required).

- Labor constraints: (reduce site operations).

- High exposure: (wind-driven rain where joints must be engineered).

🚩 Red flags (when unitized may be a poor fit)

- Small façade areas where engineering/setup costs dominate.

- Renovations with highly irregular structure.

- Projects with frequent late design changes.

- No crane access or impossible staging.

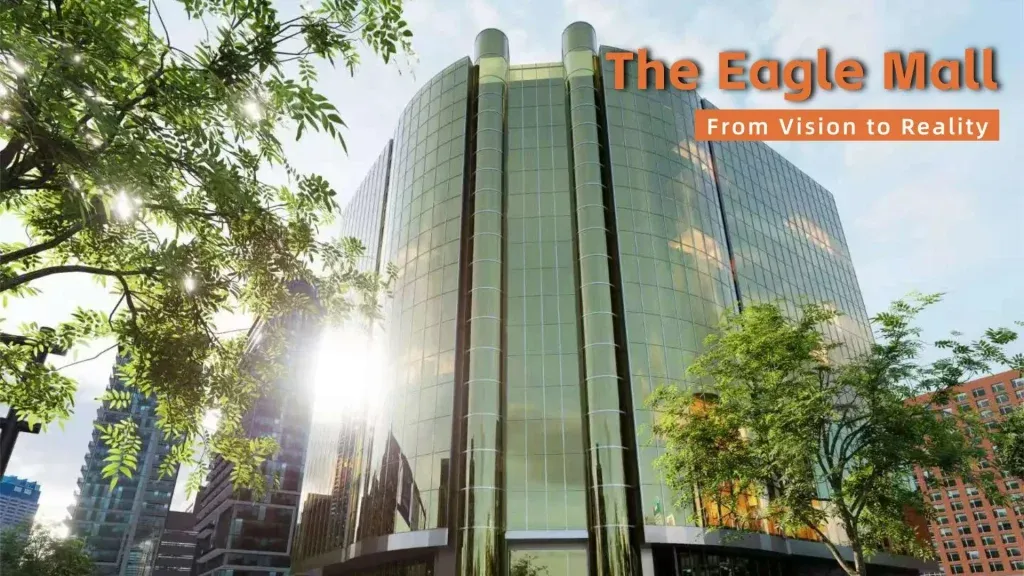

☀️ Climate and exposure considerations (Eagle Mall example)

Hot climates punish weak details. Our Eagle Mall project in Iraq is a good real-world reference because it forced the team to treat heat and site execution as first-class design inputs. The project notes emphasize extreme heat stress on materials and the need for thermal control plus safe high-level installation planning.

- Validate sealants and gaskets for temperature ranges.

- Prioritize thermal control (U-value + SHGC strategy).

- Plan installation safety systems as part of scope—not a jobsite improvisation.

📋Specification & Procurement Checklist (B2B-Friendly)

This is where buyers protect themselves: you want a spec that prevents scope gaps and change-order traps.

1) What to include in RFQ / tender requirements

unitized curtain wall specification, curtain wall performance specification, unitized curtain wall tender requirements, unitized curtain wall scope of work

Must define:

- System type: factory-glazed vs site-glazed

- Performance targets (air/water/structural/thermal/acoustic)

- Firestop/PFCS responsibilities at slab edge

- Field testing requirements

- Warranty requirements and exclusions

2) Shop drawings + submittals checklist

unitized curtain wall shop drawings requirements, curtain wall submittals checklist, unitized curtain wall details / unitized curtain wall section detail

Shop drawing must show:

- Stack joint geometry + drainage

- Anchor bracket adjustment ranges

- Thermal break continuity

- Spandrel build-up and fire interface

- Movement joint capacities (seismic drift, thermal)

3) Quality plan (ITP) + traceability

curtain wall inspection test plan ITP, traceability curtain wall fabrication, unitized curtain wall QA/QC checklist, unitized curtain wall factory quality control

Practical requirement (Ask for):

- Hold points at critical operations (glazing, gasket, sealant)

- Batch traceability for gaskets, sealants, and IGUs

- Nonconformance reporting and corrective action workflow

4) Mockup and testing requirements

curtain wall performance mock-up, curtain wall laboratory testing, curtain wall ASTM testing, curtain wall onsite water test, curtain wall air infiltration test

Tie your performance requirements to recognized test methods such as ASTM E283 (air leakage) and ASTM E331 (water penetration).

5) Packaging, shipping, and spares strategy

unitized curtain wall packaging and shipping, curtain wall transport damage prevention, spare units curtain wall strategy, unitized curtain wall fabrication lead time

Don’t skip this: define whether you’ll hold spare units (or at least spare glass and critical gaskets), and how replacement units are ordered and delivered.

🌍Real-World Case Study: The Eagle Mall (Iraq)

Project Snapshot

🔻 What problem did the project face?

- Extreme heat affecting façade materials and performance.

- High thermal insulation demand to reduce heat transfer.

- Safety risks during high-level installation + limitations of local safety systems.

🛠️ What was done after discovering the problems?

The solution described combines high thermal-insulation curtain wall system design, heat-resistant materials, and integrated scaffolding/safety systems, coordinated across design-production-installation.

✅ What was the result?

The outcomes section reports stable performance under extended heat, improved indoor comfort from reduced heat gain, and safe, controlled installation that stayed on schedule.

💡 How to use this as a buyer takeaway:

If your project is hot-climate commercial, treat the façade like an HVAC partner: specify thermal targets (U-value + SHGC), validate materials for heat exposure, and scope safety execution early—don’t leave it to “site means and methods” at the last minute.

❓FAQs

Is unitized always better than stick-built?

No. If your project is small, changes constantly, or has chaotic as-built conditions with limited adjustment capacity, a stick curtain wall may reduce risk—even if it’s slower.

What’s the typical lead time?

It depends on system complexity, mockup/testing requirements, and how fast the design freezes. Unitized rewards early decisions.

Can unitized curtain walls be repaired unit-by-unit?

Yes, but only if a replacement procedure is planned: crane access, removal path, spare parts strategy, and safe staging.

What’s the biggest cause of leaks in unitized systems?

Most often: stack joint engagement issues driven by tolerances + alignment + gasket compression consistency.

How do unitized systems handle building movement?

Through engineered movement capacity at anchors and joints—allowing interstory drift, thermal expansion, and building sway without forcing stress into the glass.