What is a Unitized Curtain Wall? Pros & Cons

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

Certification and Guarantee are vital for ensuring product reliability and customer trust.

Our commitment to quality is backed by comprehensive certifications and robust after-sales support.

NFRC, CSA C&US, AS2047, ISO, CE and so on.

Warranty periods, repair response times & surveys.

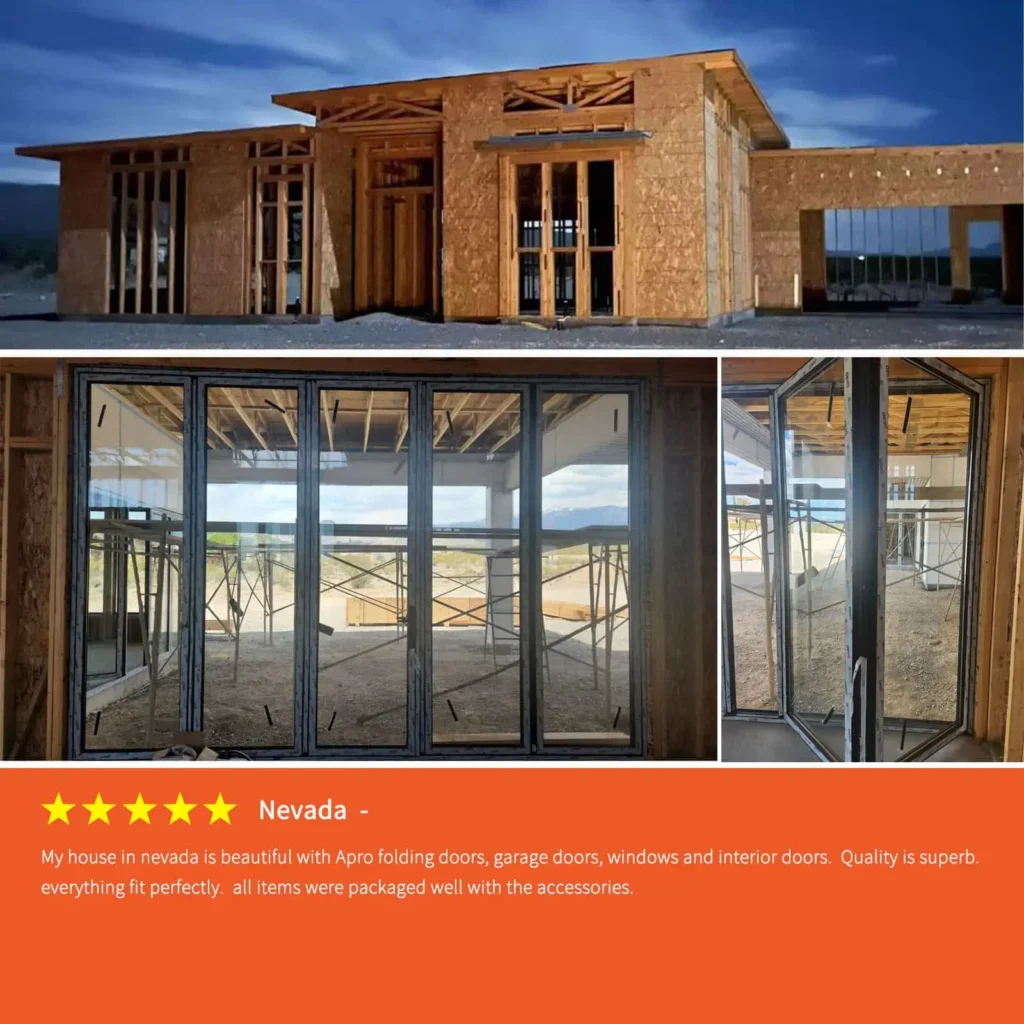

To ensure exceptional quality, we focus on meticulous standards for materials and production processes.

Material selection focuses on frame materials, glass performance, and sealing.

Production process ensures strict controls and precise assembly for quality.

The Quality Inspection System is crucial for maintaining high standards throughout production. It includes rigorous checks at every stage, ensuring excellence.

To maintain high quality, we focus on continuous improvement through various mechanisms. Our approach includes market research, R&D for new materials, and employee training.

Analyzing customer needs and industry trends for improvement.

Researching new materials and optimizing structural designs continually.

Educating staff on quality standards and enhancing skills.

A Quality Management System (QMS) is essential for ensuring consistent product quality and customer satisfaction. Below are the key components of our QMS:

Provide training programs to improve employee knowledge of quality controls and industry standards.

Conduct regular performance evaluations and offer feedback for improvement.

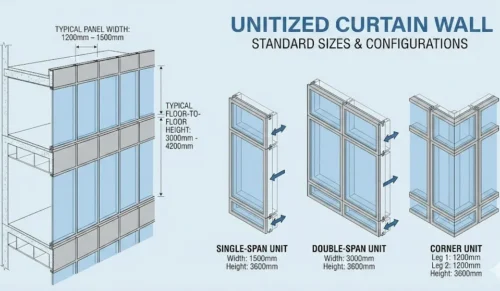

Unitized curtain wall guide: meaning, pros/cons, details, performance, install steps, QA/QC, and sourcing checklist—based on APRO factory experience.

Standard unitized curtain wall sizes explained: module width/height, frame depth, IGU thickness, joint sizing, tolerances, and case-based sizing plans.

Learn curtain wall glass types and uses: IGU vs laminated vs tempered, Low-E benefits, safety needs, and spec tips for projects

Learn what glass is, how it’s made, and how to choose: tempered, laminated, IGU, Low-E, VLT/SHGC/U-value, plus PO spec tips.

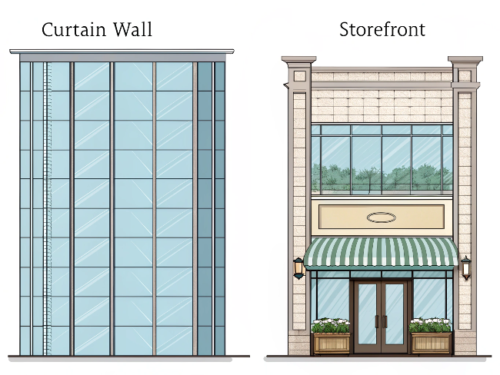

Learn its core definition, key components, performance metrics, drainage/weep details, and how it differs from curtain wall—so you can specify with confidence.

storefront vs window wall explained with clear pros/cons, costs, leak risks, and selection tips—use our decision framework to choose the right system today.

WhatsApp us